Quality testing is paramount to preventing costly and dangerous failures. By Tyler Laravuso and Jennifer Redmond

Wire Terminal Testing and Onshoring: It’s All About Connections

Test & INspection

H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Test & INspection

H2 Deck Info By Paragraph Style Bold

Headline

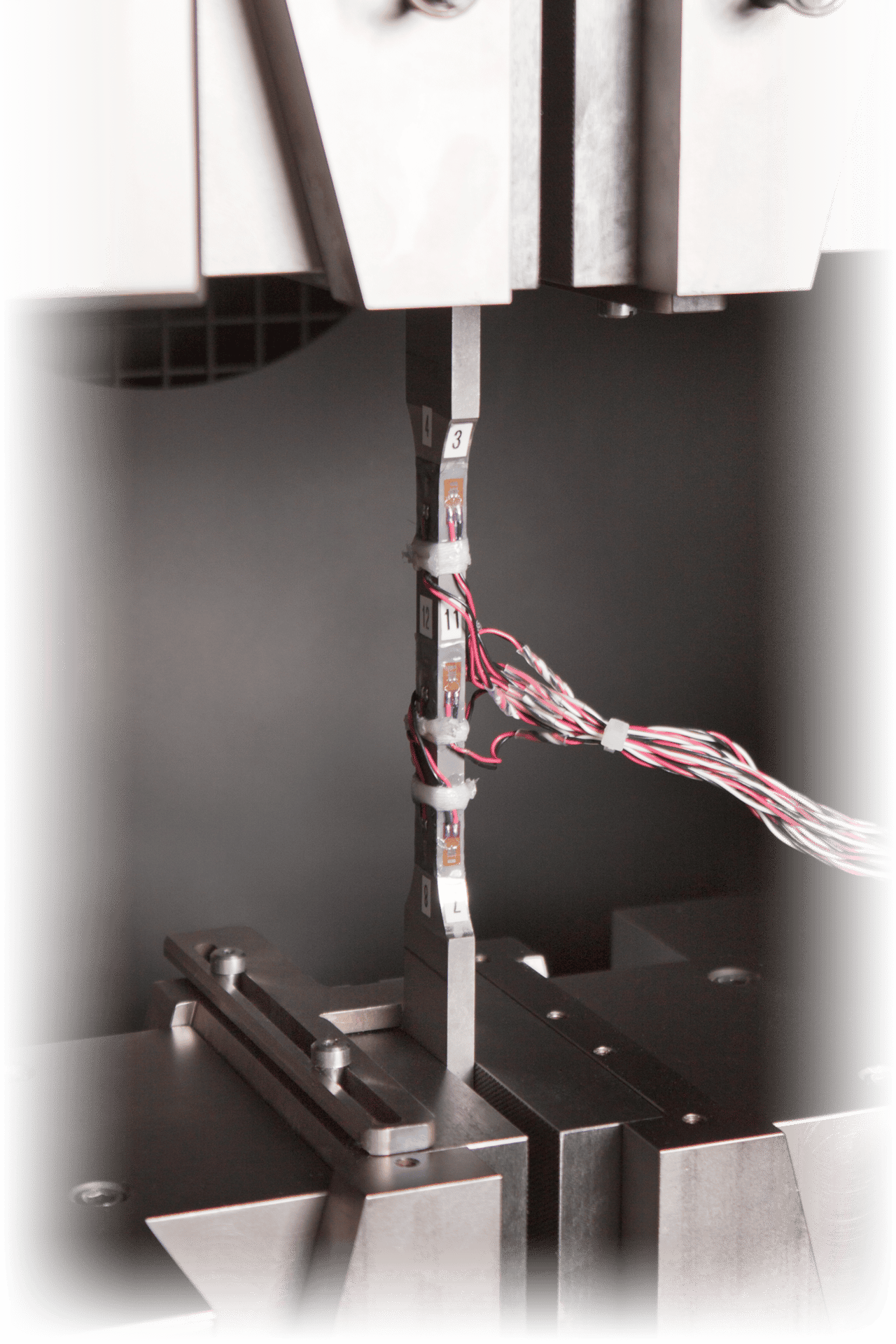

Force measurement analyzes the amount of compression (push) or tension (pull) an object experiences in order to assess its quality and performance. Testing by hand with a suitable gage or sensor is a simple and quick option, but more reliable data is achieved by benchtop systems that control the angle and speed of force actuation. One force measurement application seeing growing interest is wire terminal testing, in which a controlled pull against a crimped connection produces a force measurement, characterizing its integrity and quality.

Wire terminal testers generally involve a mechanism to apply a test force, a grip to hold the terminal, a grip to hold the wire, and a load cell and electronics to process and display the data. Force results may include a date and time stamp and pass/fail indicator according to pre-configured acceptance limits.

During the test, which can be conducted using either a lever- or wheel-operated manual system, or a motorized tester, the actuator speed should be controlled to yield the most repeatable possible results.

Three common test methods are (1) pull-to-failure, a destructive test which applies force until the wire separates from the terminal, (2) pull-to-load, where a sample is deemed acceptable if it remains attached at a target force, and (3) load-hold, where a sample is held at a target force for a specified amount of time. Results for these tests are typically measured in lbF (pound-force), kgF (kilogram-force), or N (Newton) units. Other data that may be included are test speed (in/min or mm/min) and location of failure, which can identify if there is an issue with the crimp or the wire itself. Results depend on several factors like wire gauge, type of terminal, crimping process and crimping tool condition, type/quality of wire, and environmental factors like temperature and humidity.

xxxxxxxx

xxxxxxx

Although it may seem logical that a higher force measurement represents higher quality, it’s not always the case. Higher forces may be a symptom of over-crimping, in which incorrect or faulty tools excessively crimp the terminal. Over-crimping can be just as problematic as weak crimping and may lead to a brittle, easily broken connection. Industry testing standards like UL 486A specify the force required to pull a terminal off a wire as well as the speed of the pull. These harmonized processes allow data to be seamlessly shared amongst vendors up and down the supply chain.

Supply chains today are changing. Self-shoring/onshoring, or the process of relocating manufacturing back to or near a company’s home country, has gained traction in recent years, driven not only by the need for stability in the face of external crises such as Covid, but also by a growing emphasis on national security and technological independence. Companies also recognize that onshoring can reduce transportation costs and help to rebuild technical workforces hollowed out in earlier deindustrialization cycles. Challenges remain, such as high costs and limited skilled labor pools, which industries must balance with the opportunities that arise from a more localized approach. Three industries in particular that are self-shoring and rely heavily on wire terminal testing are appliance, automotive, and aerospace manufacturing.

xxxxxxxx

xxxxxxx

Pull testing is critical in household and commercial appliances where electrical reliability is critical to performance and safety. This includes high-power appliances such as refrigerators, washing machines, dryers, ovens, and dishwashers, as well as smaller devices like microwaves, coffee makers, and vacuum cleaners. In these products, wire harnesses connect motors, heating elements, sensors, and control boards - components that demand secure and consistent electrical connections to function safely. A weak or faulty crimp in any of these appliances can lead to intermittent operation, short circuits, or overheating, posing risks to the user. Crimp pull testing ensures that each terminal can withstand the mechanical stress and thermal cycling over the appliance’s lifetime, helping manufacturers meet UL, IEC, and other relevant standards.

Automobiles are major users of wire harnesses. These must be rigorously tested for safe, dependable connections that can withstand vibrations, temperature fluctuations, and other environmental factors typical in use. Data from these tests directly influence the design and manufacturing phases, enabling engineers to refine their techniques and materials to more stringently comply with industry standards and resolve weaknesses before they reach assembly lines.

High-voltage electric vehicles (EVs) and batteries are particularly reliant on wire harnesses, where malfunctions can lead to breakdowns and hazardous situations. Successful crimps equal trustworthy connections in battery management systems, drive controls, and other EV components. This ensures proper performance, dependability, and the manufacturer’s reputation in an increasingly competitive market. In the U.S., construction of battery production facilities and EV assembly plants have grown significantly. More long-term growth is expected, despite temporarily softening in the adoptation rate of EVs.

Wire terminal pull testing is vital to the aerospace industry as well. Wire harnesses are employed in navigation, flight controls, hydraulics, engines, and almost every part of an aircraft, including cabin comforts like climate control and entertainment. Military helicopters and fighter jets use wire harnessing for additional purposes like weapons control. Space vehicles and satellites rely on them for dependable communications. These components must perform safely and optimally under extreme conditions. Quality testing is paramount to preventing costly and dangerous failures.

In these examples, localization of production requires opening new production facilities, with all of the associated challenges of construction, tooling up, and staffing. Whether it’s a barbecue or a Boeing, effective wire crimp pull testing, and uniform standards for how to perform it, help identify issues before they become hazards, keeping costs down and ensuring end-user satisfaction as production shifts closer to home.