H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Software & Analysis

Imagine catching a problem while it’s happening, not days or weeks later. By Adam Grabowski

Beyond Inspections:

The Secret to Building a Quality-Driven Manufacturing Culture

Software & Analysis

H2 Deck Info By Paragraph Style Bold

Headline

Quality isn’t a department. It’s a mindset. That mindset can mean the difference between thriving and simply surviving. The modern customer demands flawless products, delivered on time, every time. Yet for many manufacturers, quality still feels like an endless game of catch-up – reacting to problems after they happen, throwing resources at rework and trying to patch cracks in the process while the production line keeps moving.

It doesn’t have to be that way. Enter ERP: Enterprise Resource Planning software that transforms quality management from a defensive scramble into an offensive strategy.

The Shift: From Quality Control to Quality Culture

Traditionally, quality was an end-of-the-line checkpoint – inspect parts, flag defects, hope the issues don’t resurface. But that reactive cycle often breeds repeat mistakes, rising costs and frustrated teams.

A robust ERP system rewrites the playbook by integrating quality at every stage of production. Real-time data, process visibility and instant feedback loops allow quality to become proactive. Instead of chasing problems, manufacturers prevent them.

With ERP fully embedded, quality becomes everyone’s responsibility – from operators on the floor to engineers, managers and even suppliers. It’s no longer about isolated inspections but building a system where quality is woven into daily decisions and actions.

Real-Time Data: The Quality Game-Changer

ERP transforms fragmented processes into an organized system that can help you catch problems early, understand root causes and make confident decisions based on real-time data. Over time, the data collected by ERP software becomes a valuable resource for continuous improvement, allowing quality team members to benchmark performance and measure the effectiveness of changes.

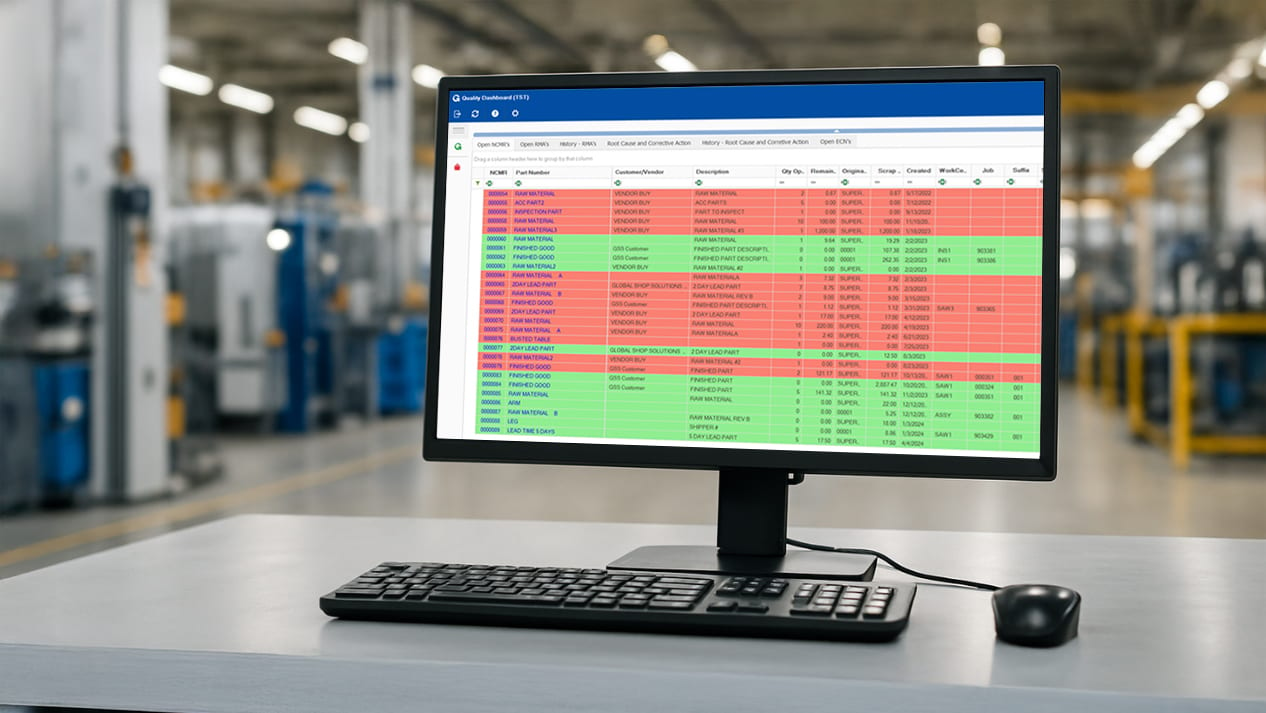

Imagine catching a problem while it’s happening, not days or weeks later. ERP makes that possible with live shop floor feedback, version-controlled documentation and integrated tracking of nonconformances, CAPAs (corrective and preventive actions) and trend reporting.

When quality becomes part of the everyday routine, everything else runs smoothly. ERP supports a proactive quality culture through:

- Real-time shop floor feedback to catch quality issues as they happen

- Version-controlled documentation to prevent errors from outdated specs

- Integrated quality tracking including NCMRs (nonconformance material reports), CAPAs and trend reporting

- Complete traceability from raw material to finished part

- Audit-ready data that makes certification and compliance less painful

Take the example of one manufacturer who achieved an astounding 99.67% quality rating. How? ERP-generated automated alerts, immediate NCMRs and job-specific corrective actions kept everyone on the same page. Operators flagged issues the moment they arose, while engineers initiated root cause investigations before flawed products even left the building.

The result? Problems were solved, not bandaged. Human error was minimized. Costs stayed down. And quality became an expectation, not a hopeful outcome. The goal isn’t just inspection, it’s full integration.

Caption

The Power of Traceability: Every Detail, Every Time

When the right data is available at the right time, teams can act fast. ERP systems make this possible by tying quality-related events, such as rejected parts, directly to work orders, job records and vendor histories. It eliminates lag between detection and action, reducing downtime and helping teams maintain delivery commitments.

For example, we’ve seen manufacturers achieve a 99%+ quality rating by using ERP to trigger automated alerts, NCMRs and approvals when deviant parts were reported. Corrective actions were attached to the job record, ensuring that operators had full context when the part returned to production. This approach minimized human error and ensured repeat issues were documented and addressed.

This level of traceability becomes even more crucial in regulated industries like aerospace, defense, and medical device manufacturing. For companies seeking ISO 9001 or AS9100 certifications, ERP isn’t just helpful – it’s essential.

- ISO 9001: ERP simplifies document management, enables rapid corrective actions and delivers the process consistency auditors demand.

- AS9100: ERP tracks every quality event with precision – who approved it, why it changed and how it meets both customer and regulatory standards.

Audits that once took days can be prepped in minutes. Every decision, revision and action is documented, making compliance not just achievable but sustainable.

Beyond Compliance: Quality That Drives the Bottom Line

The benefits of ERP go beyond certifications and passing audits. With features like serial and lot number tracking, warranty and compliance logging and built-in change management, manufacturers can trace every part from raw material to finished product. Instead of relying on gut instinct or disconnected reports, teams can use real-time dashboards to monitor key quality metrics and respond proactively. Engineering change notices, signoffs and approval workflows are all tracked within the system, making it easier to identify where and when a process shifted and how it may have impacted product quality.

Outside of tracking documentation, ERP helps quantify what quality issues actually cost. See patterns in scrap and rework, isolate problems by department or vendor and target improvements that drive measurable value. Without a clear picture of quality-related costs, manufacturers may overinvest in certain areas while overlooking others with higher impact.

ERP can break down quality metrics like scrap rate or defect count by department, employee, customer, vendor, part number, workcenter, geographic location and more. By analyzing this data, companies can make better decisions and prioritize corrective actions that are likely to yield the biggest improvements in quality and cost savings.

When manufacturers understand both where quality breaks down and what it costs, they’re in a stronger position to drive real change. Quality challenges are part of manufacturing, but with the right systems in place they don’t have to be ongoing roadblocks. ERP gives the structure and visibility to embed quality into every decision, from design through delivery.

Companies that adopt this mindset often see results quickly: scrap and rework rates drop, audit prep becomes faster, documentation becomes easier to retrieve. Operators, engineers and managers start speaking the same language because they’re working from the same data. By treating ERP as a strategic tool rather than purely administrative and preventing problems before they begin, a stronger foundation is built for performance, accountability and long-term success.

The Bottom Line: Make Quality a Competitive Advantage

Quality challenges will never disappear. But with ERP, they become opportunities for continuous improvement rather than recurring nightmares. Companies that embrace ERP as a strategic asset consistently see faster audit prep, lower scrap and rework rates and tighter cross-departmental collaboration.

By embedding quality into every process, decision and data point, manufacturers can move from firefighting to future-proofing – positioning themselves not only to meet today’s customer expectations but to exceed tomorrow’s.

In manufacturing, the best defense is a great offense. ERP delivers both.