Products

the latest products to help you improve your manufacturing process

Shimadzu Scientific Instruments AUTOGRAPH AGS-V Series Tabletop Universal Tester

Shimadzu Scientific Instruments (SSI) introduces the AUTOGRAPH AGS-V Series tabletop precision universal testing machines. Featuring a wide selection of load cell capacities, versatile control options and compatible accessories, the AGS-V Series delivers dependable testing of diverse material types.

Available in seven different models, the AGS-V Series supports load capacities from 1 newton to 10 kilonewtons, making it ideal for delicate samples and high-force testing applications. It also accommodates a wide test speed range of 0.0005 to 1500 mm/min, providing greater adaptability for various test conditions. An improved crosshead return speed of 1650 mm/min helps reduce test cycle times and boost lab productivity.

Expandable frame options are available to handle materials that undergo deformation, such as rubber and plastics. Users can increase both the testing stroke and main unit height with +250 mm and +500 mm extensions, enabling reliable tests to failure on highly elastic or stretchable materials.

With a high-speed data sampling rate of 0.2 milliseconds, AGS-V Series instruments precisely capture rapid or subtle changes in force during testing. They also offer test force accuracy down to 1/1000 of the load cell capacity, improving data reliability, particularly during the initial rise in test force. This precision reduces the need for frequent load cell changes, simplifying setup and saving time.

To further expand testing capabilities, the AGS-V Series is compatible with a comprehensive lineup of accessories, including pneumatic flat grips, a selection of extensometers and atmosphere test devices.

The AGS-V Series is powered by TRAPEZIUMX-V software, known for its intuitive interface, including a Method Wizard that guides users through test setup.

Additional software options include:

- Single software for standard tensile, compression, bending and peeling tests

- Cyclic software for durability testing involving repeated loading patterns

- Control software for creating custom test operation sequences

- Texture software for evaluating the properties of food and pharmaceutical products

- Spring software for specialized testing of spring performance

Shimadzu Scientific Instruments Inc.

www.ssi.shimadzu.com

https://www.ssi.shimadzu.com/products/materials-testing/uni-ttm/autograph-ags-v-series/index.html

Carestream NDT Bendable Digital Radiography Detector

Carestream’s Non-Destructive Testing (NDT) group announced worldwide availability for a new bendable digital radiography (DR) detector with physical properties to markets in need of capturing images around curved surfaces. The new INDUSTREX HPX-ARC 1025 PH will deliver next-generation digital imaging capabilities to streamline workflows and instantly capture high-quality images. In addition to offering unprecedented flexibility, the Carestream NDT bendable DR detector is lightweight, easily adapts to specific applications, and has a capture area of 4x10 inches (10x25 centimeters) specifically for common NDT applications.

The Carestream bendable DR detector has the flexibility to curve from a flat position to a 2-inch diameter object and instantly captures high-resolution images.

It offers reliable, close-to-edge imaging with high resolution. The detector also provides instant image access for rapid analysis during a quick examination and reduces time-consuming reshoots after inspection point.

The new bendable DR detector provides a compelling reason for the transition into digital technology. Unlike conventional devices, the Carestream bendable DR detector offers digital enhancements that allows users to experience instant, high-quality image processing and reduced dosages for faster throughput, which improves workflow efficiencies. The new features make the detector an effective solution for a wider variety of applications, specifically traditional welding inspections.

“Until now, the use of DR for NDT inspection has been limited due to size and rigid properties, making it difficult to access tight spaces and satisfy certain applications. This can be challenging for applications that require the manipulation of the detector around the inspected part or object,” said David Chan, Global General Manager for Carestream NDT. “Our customers have been looking for a solution to this problem. Carestream NDT’s bendable DR panel provides that solution, building on our leadership in radiography and long history of innovation.”

“It transforms the NDT inspection market and opens the use of DR to applications our customers never thought possible,” Chan said.

For Carestream NDT product users, the new detector seamlessly integrates with Carestream NDT’s award winning, all-in-one INDUSTREX Digital Viewing Software. This feature allows faster integration into existing workflow and enables customers to standardize on an all-in-one software platform for both computed radiography (CR) and DR inspection.

Carestream NDT

http://www.carestream.com/nondestructivetesting.html

Mahr Inc. Digimar 814 C Height Gage

Mahr Inc. announced the new Digimar 814 C height gage, designed for ease of use and efficiency in production environments. The 814 C offers practical measuring modes and functionality that simplify common dimensional measurement tasks.

The new height gage allows users to quickly and accurately measure distances, as well as inner and outer diameters, using a reliable handwheel-operated measuring slide. It features six clearly marked function keys and a high-contrast display with intuitive symbols, enabling straightforward operation with minimal training. Measuring functions include bidirectional measurement and preset value settings, and measurement data can be securely transferred directly via USB to MarCom software for streamlined documentation.

Available in 300 mm and 600 mm measuring ranges, the Digimar 814 C is built to perform reliably on the shop floor. Users can choose between a steel base or a granite table, depending on stability requirements. Additionally, the gage's robust yet portable design makes it a practical solution for a wide range of applications in production metrology.

Key features of the Digimar 814 C include:

- Practical measuring modes for bi-directional distance and diameter measurements

- Handwheel with fine adjustment for precise positioning

- Constant measuring force for consistent, reproducible results

“The Digimar 814 C is designed to deliver precise, repeatable measurements with an interface that supports high productivity,” said Dr. Farzad Azimi, Precision Gage Product Manager at Mahr Inc. “Its intuitive operation and rugged design make it an ideal fit for today’s manufacturing production environments.”

Mahr Inc.

www.mahr.com

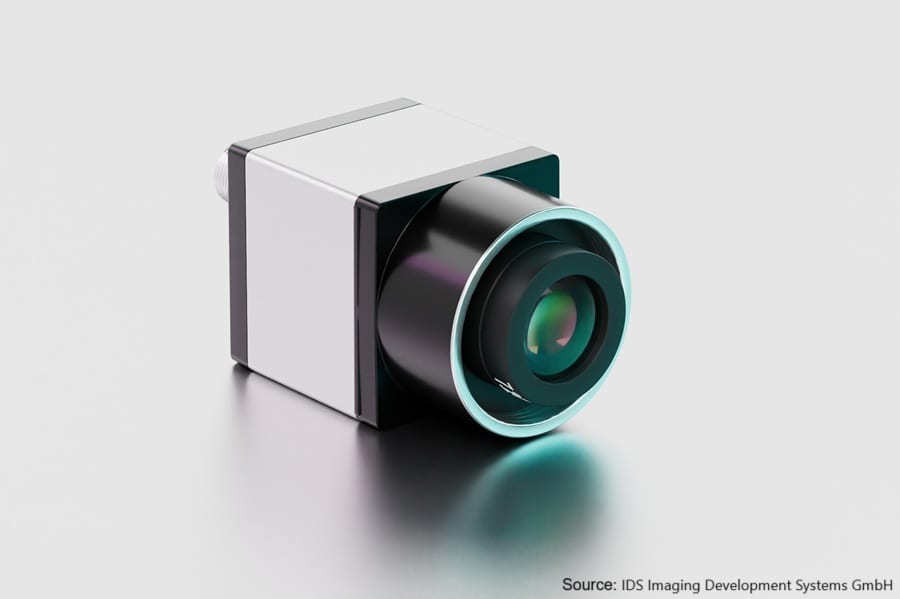

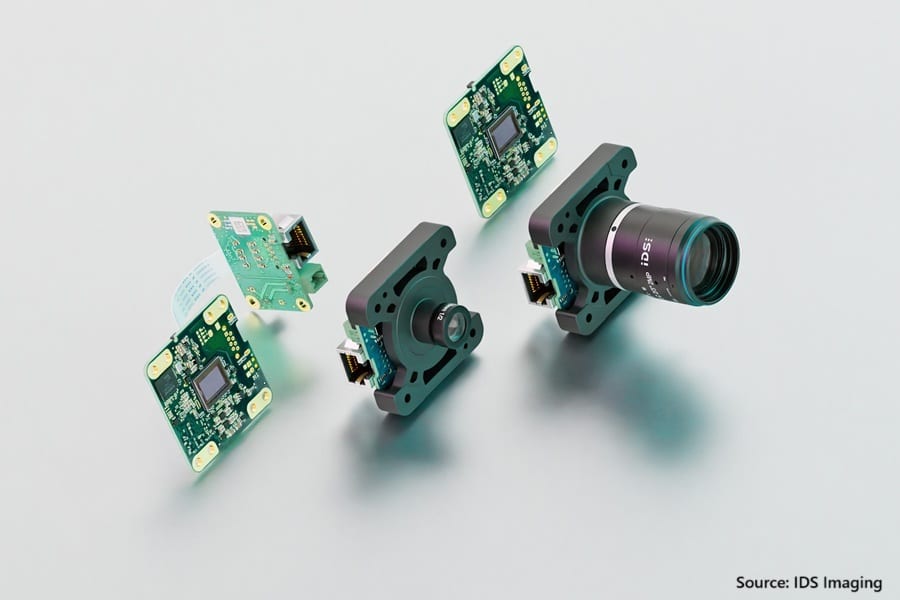

IDS Customized Industrial Cameras

Standard products are often not enough to meet the diverse needs of modern industrial companies.

IDS Imaging Development Systems GmbH, therefore, offers customized industrial cameras. The spectrum ranges from simple modifications, such as logo imprints or software customizations to completely new designs precisely tailored to the respective application, the environment of use and the customer's brand identity.

"Our customers benefit from customized camera solutions that are as special as necessary and as efficient as possible," explains Moritz Fuchs, Project Manager Customized Solutions. "Thanks to our many years of experience in hardware and software development, we accompany projects from the initial idea to the final integration, with comprehensive advice and technical support."

By minimizing development effort, companies save time, costs and internal resources. Modifications to the hardware and software of existing series products can be made quickly and easily. The highest manufacturing standards “Made in Germany” and certified processes ensure the quality of every customized industrial camera. In addition, the sustainable design of the solutions guarantees long-term availability and maximum planning security.

Whether hardware or software customization - standard solutions become individual systems. Typical customized products include individual designs, special front and lens mounts or customer-specific pre-focusing. White labelling, preconfigured settings and quality assurance agreements are possible on the software side.

"The individual adaptation of the camera to our lens changer was implemented in an uncomplicated manner - functionally, cost-efficiently and in a spirit of partnership," says Dr Christian Moitzi,,Research & Development, Anton Paar GmbH, describing the handling of the solution tailored by IDS.

IDS also develops and manufactures completely new camera systems for particularly demanding projects, including feasibility analyses, support with system integration and application-specific training. The camera thus becomes a perfectly integrated component - whether in automation, medical technology, agricultural technology or in the transport and logistics sector.

IDS also offers the modular uEye ACP system for smaller quantities that require customized configuration. Here, standardized components such as sensor boards, lens mounts and connectors can be flexibly combined - even from a quantity of one. Customers benefit from readily available, highly customizable cameras for prototype development through to series applications.

IDS Imaging Development Systems GmbH

https://www.ids-imaging.us/customised-cameras.html

Verosoft TAG Mobi EAM

Verosoft announced the launch of TAG Mobi EAM, a mobile-first EAM platform built to revolutionize how organizations in manufacturing, energy, and facility management modernize maintenance operations, strengthen workforce efficiency, and boost productivity.

As global enterprises work to navigate multi-site production, maneuver supply chain disruptions, meet sustainability goals, and mitigate a shortage of skilled labor, TAG Mobi EAM delivers a cost-effective, mobile-first, and AI-powered alternative to traditional EAM systems. Fully embedded in Microsoft Dynamics 365 Business Central, TAG Mobi EAM empowers enterprises with faster deployment and lower total cost of operations (TCOP), empowering enterprises to scale their asset operations without the complexity of legacy software.

"We wanted a fully mobile, AI-assisted EAM system to encourage user adoption," said Alexis Turgeon, Director of Innovation at Verosoft. "The AI capabilities in the TAG Mobi EAM system are designed to support users throughout their digital transformation journey by training and assisting them as they learn. Looking ahead, we are well-positioned to train AI agents that will not only simplify EAM implementations but also help drive decisions based on equipment data."

TAG Mobi EAM empowers teams to shift from reactive to preventive and predictive maintenance strategies, extending asset lifecycles and reducing downtime. By connecting TAG Mobi EAM and enterprise resource planning (ERP) environments, maintenance teams, finance, and operations can make smarter, faster decisions about equipment performance.

TAG Mobi EAM's flexible and user-based experience ensures that technicians, supervisors, managers, and operations each see only the tools and information relevant to their responsibilities, improving focus and efficiency on the job.

With built-in AI-assistance tools, TAG Mobi EAM also accelerates user training and adoption by guiding individuals through real-time workflows, which is an essential advantage in industries where skilled labor is limited and productivity demands are high.

As businesses continue to invest in infrastructure modernization and sustainable operations, the need for reliable, flexible, and future-proof asset management is imperative in a data-driven economy. TAG Mobi EAM helps medium to enterprise businesses, from regional to global innovators, to navigate this ever-changing economic landscape.

By delivering a mobile-first, AI-powered solution fully embedded in Microsoft Dynamics 365 Business Central, TAG Mobi EAM offers a scalable option to businesses looking for simplicity of use and integration within the Microsoft ecosystem.

Verosoft

verosoftdesign.com

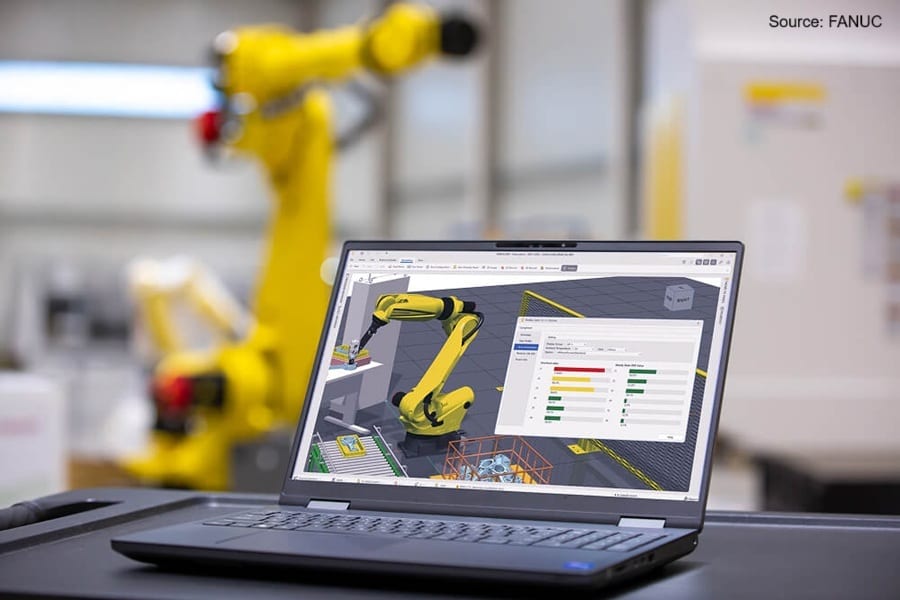

FANUC Introduces Enhanced, Next-Gen ROBOGUIDE Robot Simulation Software

Rebuilt and redesigned, FANUC announces the release of ROBOGUIDE Version 10, the latest and most advanced iteration of its offline robot programming and simulation software. Designed to enhance efficiency, visualization, and user experience, ROBOGUIDE continues to be the go-to solution for companies seeking to streamline automation design and implementation.

ROBOGUIDE allows users to create, program and simulate robotic workcells in 3D without the need for physical prototypes, reducing costs and improving accuracy in automation planning. With the launch of this next-generation software, FANUC is introducing several powerful upgrades, including:

- New Virtual Reality Capabilities – Users can now experience workcells in a fully immersive environment, improving line of sight and spatial awareness like never before. This enables engineers and operators to interact with automation designs in a more intuitive and insightful way with virtual reality playback and walk through.

- High-Performance 64-Bit Architecture – ROBOGUIDE is now a 64-bit application, delivering higher performance, increased content capacity, and improved processing power for complex automation systems.

- Modernized User Interface – Featuring a ribbon-style toolbar, floating and docking windows, and improved graphics, ROBOGUIDE V10 makes navigation more intuitive and efficient. Using a new drag-and-drop tool, users can quickly locate and define robots with ease.

- Enhanced Support for Native CAD Import – Simplifying integration and design processes, ROBOGUIDE now supports the import of many more native CAD formats, making it easier than ever to import, adjust, and optimize automation layouts.

"With the release of our enhanced ROBOGUIDE V10, we're delivering a smarter, more powerful simulation tool that meets the evolving needs of the automation industry," said Eric Potter, general manager, Robot Application Segment, at FANUC America. "Across nearly every industry, this immersive simulation software allows manufacturers to effectively visualize workcell effectiveness before actual installation, without the physical need or expense of a prototype setup.”

ROBOGUIDE V10 is now available to users alongside the previous version, sharing a single license and ensuring that FANUC customers can take advantage of the latest advancements in robotic simulation.

FANUC America Corporation

www.fanucamerica.com

XIMEA Cameras with Sony Pregius S CMOS Sensors

XIMEA has enhanced the current portfolio with models using the new Sony CMOS Pregius™ S sensors.

Following the successful market launch of the first Pregius S-based cameras in 2020, XIMEA is continuing the series with camera models based on IMX545, IMX546, IMX547 and other sensors from the Sony 4th generation Pregius S family. This generation of Sony CMOS sensors utilizes a small pixel size of 2.74 µm in combination with BSI - backside illumination technology. The small pixel facilitates the use of lower-cost optics and helps to keep the system dimensions very compact by contributing to closer proximity for multi-camera setups. The miniature size does not mean a compromise in the imaging quality which stays remarkable judging by any kind of EMVA 1288 parameters.

As with previous generations, the 4th generation continues to offer high quantum efficiency as well as lower noise and noteworthy dynamic range above 70 dB. Additionally, all sensors offer global shutter readout making them ideal not only for scientific applications, but also for systems where objects move at a higher speed. Another important factor is the availability of high-speed version equivalents for each resolution, namely the IMX535, IMX536, IMX537. The higher speed models do not only bring additional considerable improvement in frame rate, but also interesting feature set not available for standard sensors.

This is a continuous Sony trend where standard models are cheaper with the same image quality whereas high speed ones are fast and offer complimentary functionality. Among the features is the dual ADC of low and high gain modes, the fusion of which produces HDR images as a result. The processing of dual ADC is done on the sensor side, plus XIMEA added the off-sensor FPGA merging that results in the linear response curve. Further new features include the ultra-short interval between two shutters, exposure time monitoring and an improved on-sensor thermometer.

To leverage the miniature size of Sony sensors, XIMEA has integrated them into the smallest form factor measuring only 26 x 26 x 33 mm and weighing 38 grams. This is to date the most compact size for cameras with Sony Pregius S 4th generation supplied with 10 Gbit/s bandwidth. The small pixel size of 2.74 µm and thus sensor sizes from 1/1.8” to 1/1.1” help with the choice of C-mount lenses, improving the cost attractivity and allowing a smaller footprint for mobility. Power consumption is as low as 3 Watts which allows the cameras to be bus powered directly over the cable.

In regard to cables - the sensors utilize both USB3 and PCIe interfaces to offer simplicity and excellent multiple camera system synchronization.

To summarize, the sensor models joining the XIMEA portfolio with USB3 or PCIe interface provide the following parameters:

- 5.1 Mpix, Sony IMX547, color and monochrome, 2472 x 2064, 1/1.8"

- 5.1 Mpix, Sony IMX537, color and monochrome, 2472 x 2064, 1/1.8" with HDR and other features

- 8.1 Mpix, Sony IMX546, color and monochrome, 2856 x 2848, 2/3"

- 8.1 Mpix, Sony IMX536, color and monochrome, 2856 x 2848, 2/3" with HDR and other features

- 12.4 Mpix, Sony IMX545, color and monochrome, 4128 x 3008, 1/1.1"

- 12.4 Mpix, Sony IMX535, color and monochrome, 4128 x 3008, 1/1.1" with HDR and other features

XIMEA

http://www.ximea.com

ABB Expands Large Industrial Robot Portfolio

ABB Robotics is expanding its large robot portfolio with the launch of the IRB 6730S, IRB 6750S and IRB 6760. The introduction of these new robots, alongside the wider portfolio of next generation robots launched since 2022, now means the company can offer its customers the most comprehensive lineup of industrial robots and variants on the market. The lineup of 11 next generation robot families comprising 60 variants offers customers new levels of flexibility and choice as well as class-leading performance and sustainability benefits.

“The launch of our new robots supports our vision that ‘versatility' will be the defining factor for robotics in 2025,” said Marc Segura, President - Robotics Division at ABB. “This market-leading range of industrial robots and variants, coupled with our comprehensive portfolio of mechatronic platforms, cobots, and AMRs, ensures we are ideally placed to support our customers as we enter a new world of increased productivity and flexibility. And our automation solutions can help companies to address challenges such as labor shortages while supporting sustainable operations.”

The IRB 6730S and IRB 6750S are both shelf-mounted robots and have been designed to support an increase in robot density in the production line. Capable of handling industry-leading payloads of up to 350 kg, the shelf robots can be installed at a height (or on a second floor) and can work with floor-mounted robots to maximize productivity. In addition, the robots provide excellent full vertical and horizontal motion to increase downward reach, making them ideal to optimize the space for die casting, injection molding, and spot welding for use in automotive, foundry, construction, and general manufacturing industries.

The new IRB 6760, a member of ABB’s latest generation of press tending robots, is the highest performance solution to date for mid-sized press lines. When combined with ABB’s carbon-fiber tooling boom, it can boost production output to a market-leading rate of up to 15 strokes per minute or 900 parts per hour. The IRB 6760 press tending robot is recommended for automotive, electronics and general manufacturing industries.

All three new robots are powered by OmniCoreTM, ABB’s advanced controllers for automation, delivering a 20% reduction1 in energy consumption and class-leading performance. For example, the IRB 6750S in conjunction with an OmniCoreTM controller can deliver path accuracy down to 0.9 mm.

The comprehensive lineup of next generation robots has been launched to work in partnership to further optimize plant performance. For example, ten IRB 6730S or IRB 6750S shelf-mounted robots can work in unison with eight floor-mounted IRB 6710~IRB 6740 robots to increase the number of spot welds on a car body from 70 to 80 joints in just 15 seconds, compared to predecessors. In addition, the modular design of the lineup can help reduce total cost of ownership through shared spare parts and service tools.

ABB Robotics & Discrete Automation

https://new.abb.com/products/robotics/robots/articulated-robots/irb-6750s

go.abb/robotics

VC MIPI Cameras with Cables up to 10 Meters

Vision Components presents its modular VC MIPI Bricks system with new micro-coax and GMSL2 cable options. They enable to build MIPI-based embedded vision systems with cable lengths of up to 10 meters between the camera module and processor board. The new micro-coax cable comes standard with I-PEX connectors and allows cable lengths of up to 100 cm without additional hardware. Adapters are available for the camera and processor-board sides, which simplify testing and prototyping.

The VC MIPI Bricks system includes over 50 VC MIPI Cameras and perfectly matched accessories, from lens holders to FPGA accelerator boards. The cable options include FPC cables in standard lengths of 60 mm, 100 mm and 200 mm and in variants for all common processor boards, as well as custom cables, for example with inputs for external trigger signals or flash outputs. With the new micro-coax cables, cameras can now be connected at a distance of up to 100 cm with high transmission frequency and full four lanes, ideal for applications with remote sensor heads, confined spaces, and other areas of use that require maximum flexibility. For the micro-coax cables, VC relies on twisted and shielded cables with up to 30 strands. Active components are not necessary, so the cables can be used without additional hardware. Vision Components has developed adapters for the standard I-PEX connectors that enable the VC MIPI Cameras to be connected to a standard flex cable socket for 22-pin ribbon cables at the other end. They simplify the rapid setup of functional samples and prototyping.

If even longer cables are required, for example for special vehicles or for connecting several distributed camera modules to a processor board, the VC MIPI Cameras are also available with a GMSL2 option for high-speed data transmission via serial signals. The necessary serializer is integrated into the camera design, to which the cable with MMCX connector can be directly connected. A deserializer with adapter is also available, so that the cameras can be connected directly to a processor-side MIPI CSI-2 interface during prototyping.

The cable options are part of the VC MIPI Bricks system. This also includes other options such as repeater boards, which enable longer cable lengths even when using standard FPC cables. The boards also feature additional interfaces for external triggers or a flash trigger output. Lens holders and other accessories are also available in the modular kit and can therefore be obtained from VC as a single source. On request, Vision Components configures ready-to-use cameras with the components, which are delivered fully assembled and calibrated. VC also carries out individual customization of the modules. For complete, tailor-made embedded vision systems and development support from the initial idea to integration, the experts at Notavis are available. The company is part of the VC Group and specializes in the development of embedded vision systems.

Vision Components GmbH

www.vision-components.com

www.mipi-modules.com

Shimadzu Scientific Instruments AUTOGRAPH AGS-V Series

Shimadzu Scientific Instruments (SSI) introduces the AUTOGRAPH AGS-V Series tabletop precision universal testing machines. Featuring a wide selection of load cell capacities, versatile control options and compatible accessories, the AGS-V Series delivers dependable testing of diverse material types.

Available in seven different models, the AGS-V Series supports load capacities from 1 newton to 10 kilonewtons, making it ideal for delicate samples and high-force testing applications. It also accommodates a wide test speed range of 0.0005 to 1500 mm/min, providing greater adaptability for various test conditions. An improved crosshead return speed of 1650 mm/min helps reduce test cycle times and boost lab productivity.

Expandable frame options are available to handle materials that undergo deformation, such as rubber and plastics. Users can increase both the testing stroke and main unit height with +250 mm and +500 mm extensions, enabling reliable tests to failure on highly elastic or stretchable materials.

With a high-speed data sampling rate of 0.2 milliseconds, AGS-V Series instruments precisely capture rapid or subtle changes in force during testing. They also offer test force accuracy down to 1/1000 of the load cell capacity, improving data reliability, particularly during the initial rise in test force. This precision reduces the need for frequent load cell changes, simplifying setup and saving time.

To further expand testing capabilities, the AGS-V Series is compatible with a comprehensive lineup of accessories, including pneumatic flat grips, a selection of extensometers and atmosphere test devices.

The AGS-V Series is powered by TRAPEZIUMX-V software, known for its intuitive interface, including a Method Wizard that guides users through test setup.

Additional software options include:

- Single software for standard tensile, compression, bending and peeling tests

- Cyclic software for durability testing involving repeated loading patterns

- Control software for creating custom test operation sequences

- Texture software for evaluating the properties of food and pharmaceutical products

- Spring software for specialized testing of spring performance.

Shimadzu Scientific Instruments

https://www.ssi.shimadzu.com/products/materials-testing/uni-ttm/autograph-ags-v-series/index.html

Eddyfi Cypher Ultrasonic Inspection Platform

Eddyfi Technologies announced the commercial release of Cypher®, a new portable ultrasonic inspection platform built to deliver faster, clearer, and more confident inspections in the world’s most demanding environments. With an emphasis on high-performance imaging, intuitive workflows, and field-ready durability, Cypher is poised to redefine expectations in advanced nondestructive testing.

“Cypher is a response to what our customers have been asking for—more speed, more clarity, and less friction in the inspection process,” said Dominic Giguère, Product Manager at Eddyfi Technologies. “It’s the most advanced ultrasonic platform we’ve built, but also the most accessible. Everything just works.”

Built on years of field insight and application engineering, Cypher combines the high-resolution performance of total focusing method (TFM) with intuitive touchscreen setup and seamless accessory detection. The result is a new standard for phased array ultrasonic testing (PAUT): inspections that are faster to deploy, easier to perform, and more consistent to repeat.

Cypher empowers inspection teams to act with certainty—no matter their experience level. Cypher combines advanced ultrasonic performance with field-ready design and effortless usability.

Key capabilities include:

- Fastest TFM inspection speed available on the market for accelerated decision-making in critical inspections

- Intuitive touchscreen setup through a 12.1-inch or 307-millimeter glove-ready, sunlight-readable display

- Automatic probe and scanner detection to minimize setup errors and optimize uptime

- Seamless live support for PAUT, time-of-flight diffraction, phase coherence imaging, and plane wave imaging to cover a wider range of applications

- IP65 environmental protection and MIL-STD-810G drop resistance for rugged reliability in harsh conditions

- Cloud-enabled data synchronization for real-time reporting, collaboration, and analysis

Designed from the ground up to thrive in real-world environments, Cypher features hot-swappable batteries and a ruggedized design—ensuring inspectors stay productive whether operating in offshore conditions, refinery shutdowns, aerospace assembly lines, or beyond.

Cypher also reflects a broader evolution at Eddyfi Technologies: advancing not only ultrasonic technology, but the way the company partners with clients. The launch marks a new era where innovation and customer success move forward together—empowering organizations to prioritize risk, protect assets, and achieve lasting value through inspection excellence.

“Cypher represents what’s next for Eddyfi Technologies and for our industry,” added Giguère. “It’s about delivering tools that empower action, clarity that drives decisions, and partnerships that help our customers succeed long after the first scan.”

From refinery shutdowns to aerospace manufacturing floors, Cypher meets the growing need for speed, precision, and reliability in ultrasonic testing. It streamlines the complex and strengthens results—reducing errors, increasing throughput, and helping teams protect the assets that matter most.

Eddyfi Technologies

https://www.eddyfi.com/en/product/cypher

B&K Precision DAQ3120 Benchtop Data Acquisition System

The DAQ3120 Benchtop Data Acquisition System is a modular solution that combines a 6½-digit digital multimeter (DMM) and a data logger in one compact design. With three module slots and five available modules to choose from, users can configure their DAQ3120 System to meet their specific application needs.

Features and Benefits:

- High accuracy and versatile measurements with a basic DCV accuracy of 0.0035%, and analog-to-digital conversions for temperature, AC/DC voltage and current, resistance, frequency, period, capacitance, and strain.

- Store up to 100 kpts of data in non-volatile internal memory, complete with time-stamps for all readings.

- Features a large 4.3" TFT color display and an intuitive user interface.

- Flexible remote connectivity with LAN, USB (USBTMC and USBVCP), and optional micro GPIB.

B&K Precision

https://www.bkprecision.com/

LUCID Triton10 High-Speed 10GigE Industrial Camera

LUCID Vision Labs, Inc., announced the launch of its new Triton10 camera family. Featuring Sony’s latest CMOS sensors ranging from 5.0 MP to 24.5 MP, the Triton10 delivers high-speed imaging over a 10GigE interface with RDMA support.

Built on LUCID’s Factory Tough™ platform, the compact IP67-rated Triton10 is designed for space-constrained environments, offering protection against dust and water along with a 17-pin M12 GPIO. The Triton10 with RDMA support enables zero-copy, high-throughput streaming—up to 1.2 GB/s directly to main memory—bypassing the CPU and OS. This significantly reduces latency and CPU load, making it ideal for multi-camera, high-bandwidth applications.

As an active contributor to the GigE Vision standards committee, LUCID supports the integration of RDMA into the upcoming GigE Vision 3.0 standard, driving broader adoption of high-speed Ethernet technologies like 10GigE and 25GigE.

“The Triton10 leverages a robust RDMA ecosystem with readily available industrial components,” says Rod Barman, Founder and President of LUCID. “It offers a cost-effective and accessible solution for demanding 10GigE Ethernet vision systems, and is ideal for applications such as automated inspection, robotics, and high-speed production lines, where performance and reliability are critical.”

All LUCID cameras conform to the GigE Vision 2.0 and GenICam3 standards and are supported by LUCID’s proprietary Arena software development kit (SDK). The Arena SDK provides easy access to the latest industry standards and software tools. It is compatible with Windows, Linux 64-bit, and Linux ARM operating systems, and supports C, C++, C#, and Python programming languages.

The new Triton10 models are available to order.

LUCID Vision Labs, Inc.

www.thinklucid.com

GigE uEye LE with Sony Starvis 2 Sensors

IDS is expanding its portfolio of GigE uEye LE single-board cameras to include models with Sony Starvis 2 sensors.

Whether in quality assurance, medical technology or automation - industrial image processing places high demands on precision and reliability, even under difficult conditions. IDS Imaging Development Systems GmbH is therefore expanding its portfolio of cost-optimized project cameras from the GigE uEye LE series with state-of-the-art Sony Starvis 2 sensors from the end of June 2025. These deliver impressive image quality even in low ambient light.

The new single-board cameras are GigE Vision-compliant, space-saving and designed for high-volume

applications. Thanks to their attractive price-performance ratio, they are suitable for cost-critical industrial projects. With the IMX675 (5 MP), IMX676 (12.5 MP) and IMX678 (8 MP) sensor variants, IDS will soon be able to offer further high-performance options for a wide range of requirements. The 12.5 megapixel version with its square 1/1.6" sensor is ideal for use in microscopy applications, for example.

GigE uEye LE: Design-to-cost single-board cameras for integration in machines, devices and embedded systems with a wide range of sensors and lenses.

The Sony Starvis 2 sensors utilize the latest CMOS technology, which impresses with excellent light sensitivity, low noise and an extended dynamic range. They were developed for applications where the highest image quality is required and guarantee detailed pictures even in difficult lighting conditions.

The introduction of the new models strengthens IDS's position as a supplier of versatile, powerful and economical image processing components - "Made in Germany". Like all members of the GigE uEye LE family, they follow the design-to-cost principle and are aimed specifically at users who want to efficiently integrate camera technology into machines, devices or embedded systems.

IDS Imaging Development Systems GmbH

www.ids-imaging.com