How new tools—including 3D laser scanning and probing devices—can help the industry innovate and adapt in an increasingly competitive (and tariffed) world. By Daniel Teigman

Beyond the Factory Floor: Why Smarter Tools Mean Smarter Quality Control for U.S. Manufacturers

measurement

How new tools—including 3D laser scanning and probing devices—can help the industry innovate and adapt in an increasingly competitive (and tariffed) world. By Daniel Teigman

Beyond the Factory Floor: Why Smarter Tools Mean Smarter Quality Control for U.S. Manufacturers

measurement

H2 Deck Info By Paragraph Style Bold

Headline

When was the Golden Age of U.S. manufacturing? I recently did a Google search to find out. While I expected a .gov or .edu stat or reference to post-World War II, I didn’t expect that the first hit would be from the House of Representatives Ways & Means Committee with the bold title: “The Golden Age of American Manufacturing Starts with the Extension of the Trump Tax Cuts.”

Kudos to whoever worked the algorithms to achieve top rank.

Politics aside, a more objective answer is in fact the late 1940s through the early 1980s. This was the period where, as a percentage of GDP, manufacturing had the largest piece of the American pie, at around 21-25%. It was also a time of high wages, (mostly) low inflation, and widespread union membership. In 1979 at its peak, nearly 20 million Americans were directly employed in some form of manufacturing. Today that figure is below 13 million, a 35% decrease.

Setting the Stage for Manufacturing Success

But as evidenced by the Ways & Means proclamation, American manufacturing is again a hot topic. Whether or not the country is on the verge of a new Golden Age is up for debate.

What’s unequivocal though, is that if we are on that exciting new precipice, the future of manufacturing belongs to companies that can move faster, train smarter, and deliver consistent quality with fewer barriers toward finished results.

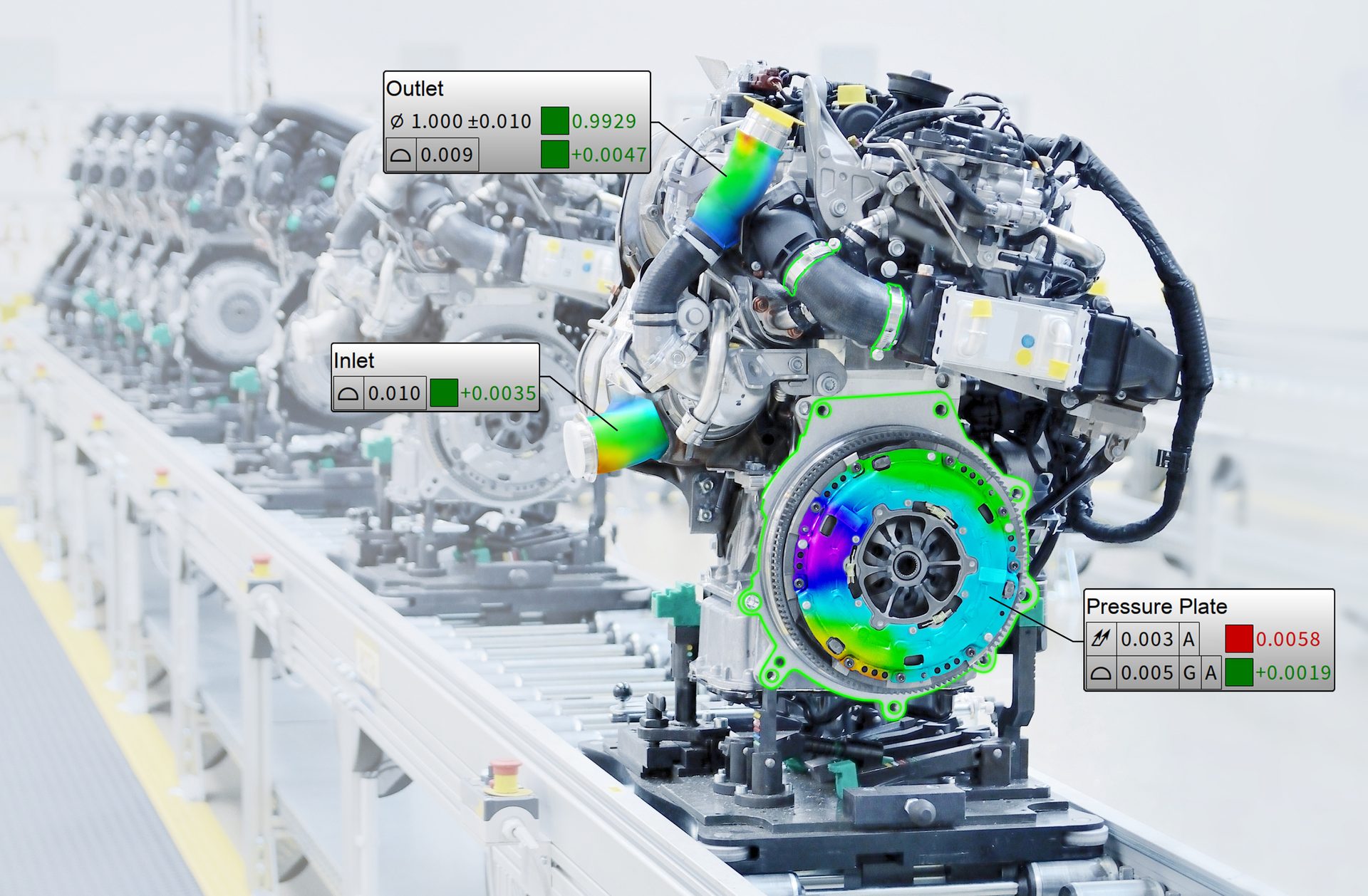

And one of the key methods of achieving this coveted four-way win is through adopting portable 3D scanning and probing technologies. Collectively, these solutions make complex inspection tasks simpler. They accelerate production. They feature simpler learning curves. They require fewer personnel to operate. They allow teams to streamline workflows with greater part accessibility. They reduce rework, waste, and scrap. And they scale productivity through increased throughput.

These tools aren’t just upgrades—they’re strategic enablers for modern factories looking to stay competitive, agile, and proud of the quality of their work.

But before focusing on the present, first a nod to the past. Perhaps the greatest myth surrounding the Golden Age of Manufacturing was that it was, in fact, efficient – at least compared to today.

The truth is it wasn’t. Not by a long shot.

Caption

Source: FARO

Dispelling Manufacturing Myths

While the industrial revolution had begun in the 18th century, ostensibly to increase the number of goods produced with the advent of labor-saving machines (first by waterpower, then steam, then internal combustion) even by the 20th century manufacturing remained a highly labor-intensive process.

Mega factories like the now-largely demolished Detroit Packard Automotive Plant, for instance, at its peak employed over 40,000 workers and sprawled across 3.5 million square feet. (For reference, today’s residential population of Greater Downtown Detroit is about 37,000 across 7.2 square miles.)

Inside these behemoth factories quality control and quality assurance were largely manual tasks. As factory workers tended to individual parts and subassemblies, entire quality control departments were established to oversee the craftmanship produced. As output increased, it became impractical to inspect every single part.

The Birth of Statistical Quality Control

To address this challenge, visionaries like Walter Shewhart and W. Edwards Deming, a statistician with the U.S. Department of Agriculture and Census Bureau, began implementing statistical quality control, defined as “employing inspection methodologies derived from statistical sampling theory to ensure conformance to requirements.” Under SQC guidelines, samples are inspected from a batch and conclusions are drawn on the entire batch based on statistical inferences.

While no doubt a significant QC leap, it’s clear that this approach had its challenges. Key drawbacks include but are not limited to: data quality, interpretation and communication, expertise of use, time and resources expended, risk of false positives, (and unnecessary parts rejection), cost, productivity and overreliance on historical data.

Above all, SQC requires accurate and complete data, and poor data quality can lead to inaccurate findings. In addition to data quality is the need to explain one’s analysis to stakeholders, say a production manager. Both the volume and complexity of the data can make this difficult.

Source: FARO

How 3D Solutions Measure Up

Today, cutting costs in just the QC arena alone has profound advantages. For starters, the use of innovative, accessible technology, like 3D laser scanning and probing solutions makes local production a stronger business case.

How? By acquiring better, more accurate data on the shop floor as parts are being assembled means greater productivity. Combined with automated and semi-automated machines, guided by controlling software, this has a significant cost reduction value.

With tariffs on imported aluminum and steel now as high as 50% (as of June 4, 2025) from some markets and holding at 25% from the U.K., any way to reduce rework, waste and scrap is key in savings elsewhere, reducing the odds that those de-facto taxes are passed on to consumers. The less consumers shell out and the longer prices stay stable, the longer consumer confidence remains high, leading to more spending and the continuance of a healthy economy.

3D measurement solutions offer additional advantages too.

Ease-of-Use, Eager Employees

Intuitive and easy-to-use 3D scanners and portable coordinate measuring machines (CMMs) along with inspection software, all help shorten the operator learning curve, while providing superior in-process data.

Moreover, by transitioning from novice user to near-expert handler, faster, helps teams expand skills on the job without slowing down operations.

What’s more, the factory of today is also taking a page from the past, increasingly tapping into apprenticeships and embracing earn-and-learn programs, some as part of on-the-job training and others through academic partnerships. In either case, 3D technology is finding its way into the hands of the next generation of employees. Unfettered by restrictions from the past and eager to embrace change, these younger Millennials and GenZers are tomorrow’s tech-enabled workforce.

As a result, as these partnerships expand – in 2024, there were over 96,500 apprentices in advanced manufacturing industry alone, and this number is expected to increase – the U.S. will for the first time in decades, shorten the education/technology gap.

“Here’s to you, America”

For an article commenting on the state of U.S. manufacturing and quality control, it’s fitting, perhaps, to wrap up with referencing one of the country’s more enduring automotive marketing commercials by Chrysler Motors (now Stellantis North America), complete with its catchy jingle.

If you’re among a certain generation that recalls them either from their youth, college days, or early working years, these late 1980s and early 1990s TV (and radio) ads were bursting with American pride and included soaring images of the Blue Angels -- their red, white, and blue contrails streaking behind.

While our current Chief Executive remains a complex messenger, certainly no one can deny the power (and intended positivity) of his central slogan: Make America Great Again. It’s that kind of forceful messaging that underscores the House Ways & Means Google-topping link – a stylistic nod to the “Morning in America” optimism of the late-Reagan era.

A Homerun for the Home Team

But that kind of patriotism, that kind of can-do American spirit isn’t just a 1980s relic. And it’s not just part of some throwaway jingle. Nor is it lettering emblazoned on a hat. It’s the heart and soul behind so many American-made products. Products in transportation equipment, in chemicals, in heavy machinery, and computer and electronics. It’s imbued in the food we produce and export, and the petroleum and coal products we sell.

Whether it’s our cars or our aircraft and helicopters, the innovations that define the future of American manufacturing success are, in the final analysis, powered by people.

And the increasingly smart 3D laser scanning and probing technologies they (we) continue to produce.