H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Case Study

The software has been transformative for PCC Airframe, enabling the team to maintain high standards while improving operational efficiency. By DISCUS Software Company

PCC Airframe Achieves Enhanced Efficiency and Consistency with Discus Software’s IDA

Case Study

H2 Deck Info By Paragraph Style Bold

Headline

PCC Airframe, a leader in the aerospace industry, specializes in manufacturing complex airframe components. Based in Northern Kentucky, PCC Airframe provides high-quality parts across a global market and consistently meets the stringent requirements of the aviation sector. The company’s dedication to precision and innovation ensures that it remains at the forefront of aerospace manufacturing, delivering products that support the safety and performance of aircraft worldwide.

The Challenge

Before implementing DISCUS Software, the PCC Airframe team faced significant challenges in their quality control processes. Dustin Teter, Product Integration Engineer, says their previous method involved manual hand ballooning and notation for blueprint creation, which was labor-intensive and prone to inconsistencies.

“We never had any software prior to DISCUS,” he recalls. “Notations, learning, data entry for the spreadsheets and FAIs — all of it was done by hand.” Naturally, this caused a long list of key issues, including:

- Lack of electronic consistency, leading to discrepancies in balloon drawings across different engineers.

- Time-consuming manual data entry.

- No electronic traceability, making it difficult to track and reuse previous data accurately.

- Damaged blueprints that exacerbated inconsistencies when different engineers worked on the same projects.

These challenges not only slowed down the production process but also increased the risk of errors, ultimately affecting the efficiency and reliability of the company’s operations.

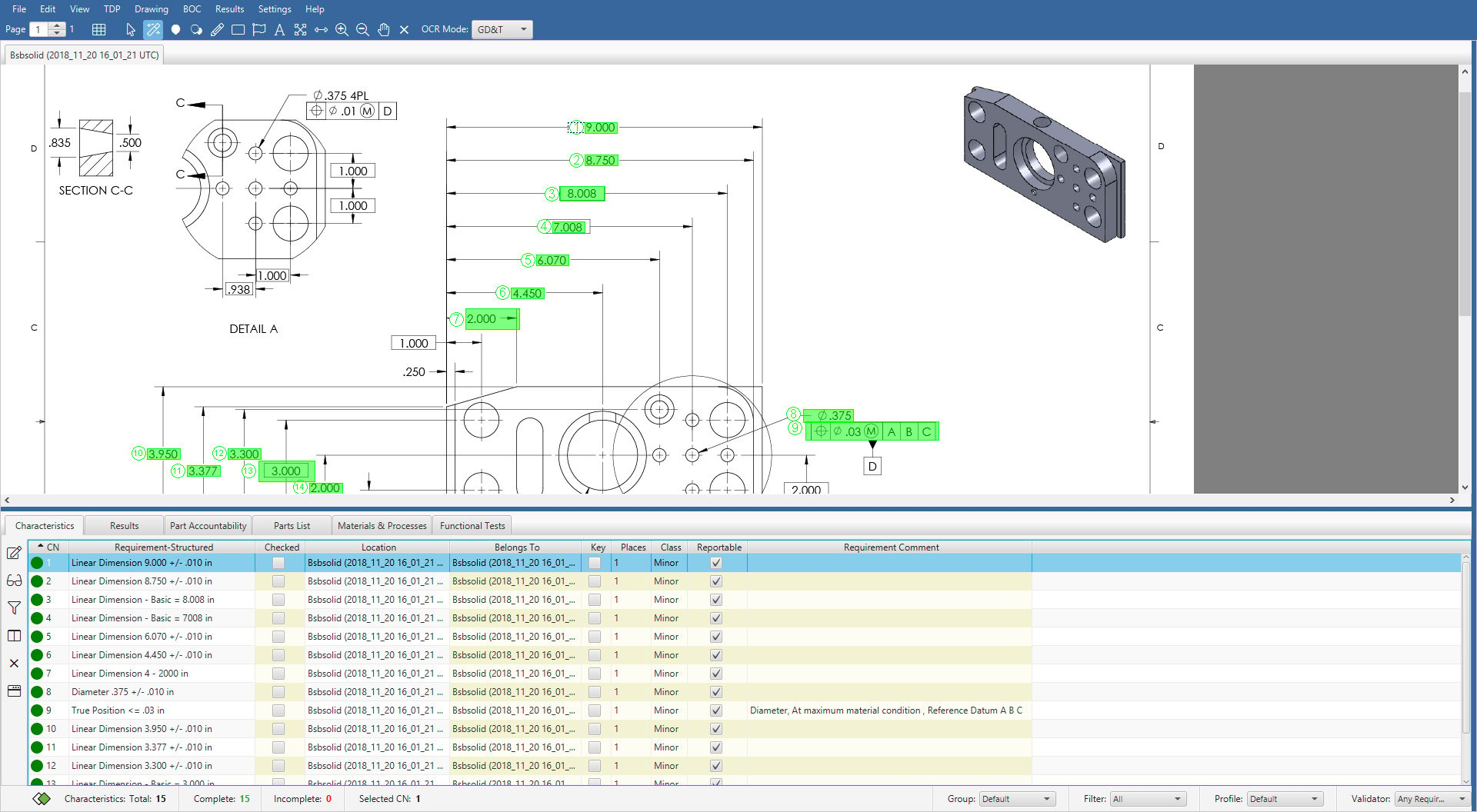

Caption

The Solution

At the time, one of the previous PCC Airframe engineers was retiring, leaving Teter to make new decisions that would shape the company’s future. One such decision was embracing the power of advanced technology. “I was like, ‘Hey, this is sweet. I can do everything via computer,’” he says.

Of course, there was one initial obstacle: the old ways. Some of his team had been using tried-and-true methods for 30 years, and Teter and his technology represented unfamiliar solutions and functionality.

Fortunately, getting buy-in was easy once Teter discovered and ultimately chose DISCUS Software. Several factors drove this decision:

- Proximity and ease of communication with DISCUS Software, located close to PCC Airframe in Ohio.

- Direct support from DISCUS to tailor the software setup for seamless integration with existing customer requirements.

- The capability and functionality of the software itself, including the then-forthcoming Intelligent Drawing Analysis (IDA), which would streamline and standardize the ballooning and data entry processes.

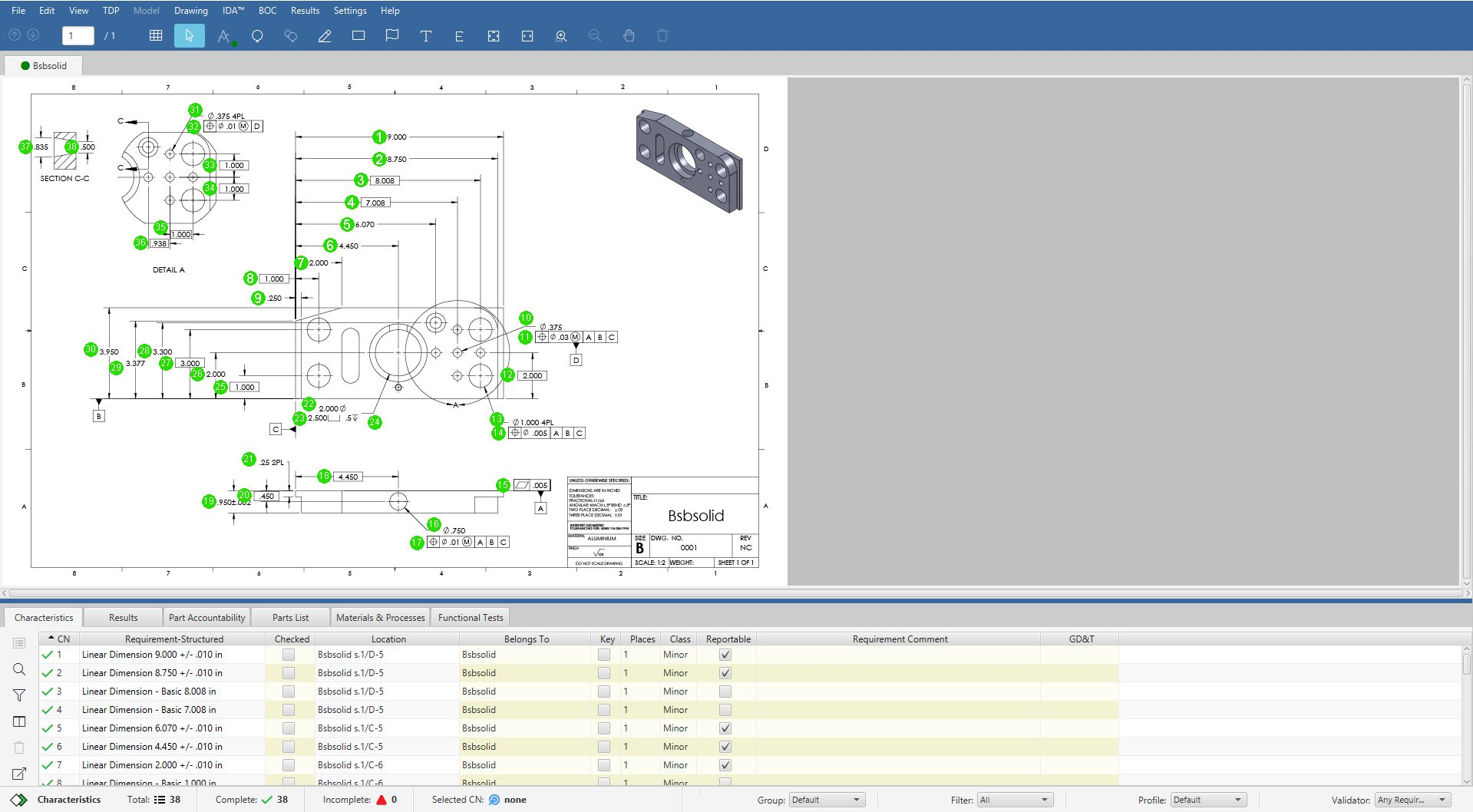

Caption

Teter remembers valuable conversations with the DISCUS team early on, noting that one especially crucial element was “the ease of getting the relationship started up and having direct contact to work through the process.” From there, he says the new solutions were “welcomed by everyone from the front side of engineering to the guys on the shop floor.”

When everything was in place, the DISCUS and PCC Airframe teams were ready to begin addressing key issues with a targeted implementation process. This was no small feat, considering Teter estimates that the company handles anywhere between 50 and 100 FAIs per month. Some periods even climb to 1,500 or more, which Teter says is “pretty wild.”

Fortunately, DISCUS solutions were well-equipped to handle this level of demand and variation, helping the PCC Airframe team optimize processes that needed to work across multiple customers. Implementation included:

- Formatting and translating existing data into DISCUS to populate the correct fields in Excel spreadsheets.

- Uploading these spreadsheets into customer databases, ensuring compatibility and accuracy.

- Fine-tuning the data export to meet specific customer needs, eliminating unnecessary columns and rows.

For example, Teter recalls one project that relied on the DISCUS team helping create a custom template per the customer’s requirements.

“We could just export the data straight into those spreadsheets and have it already set up, per that specific customer,” he says. Soon, similar solutions were at work across the organization, making DISCUS Software an answer to everyday challenges.

In the early days of the relationship, Teter and his team were relying on a now-historical solution called optical character recognition (OCR). After recently renewing his software subscription, Teter recalls noticing something new: IDA. Although he and his team had questions at first, they quickly realized that IDA represented the new generation of OCR-based technology — and now they’re using it to its full potential.

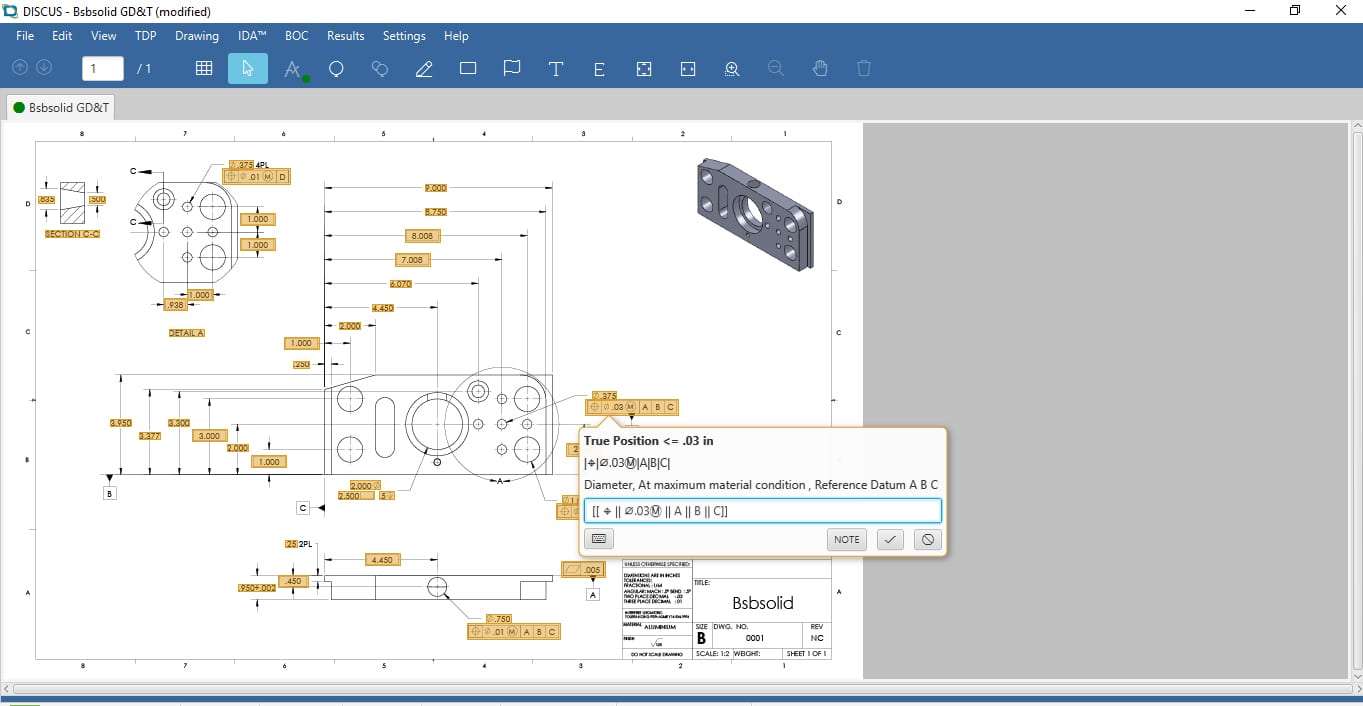

Caption

The Results

Since implementing DISCUS Software solutions including IDA, PCC Airframe has experienced substantial improvements in their operations. The immediate and long-term benefits of the solution are evident in several key areas:

- Increased Efficiency: The automated processes have significantly reduced the time required for ballooning and data entry.

- Enhanced Consistency: Standardized procedures have ensured uniformity across all quality assurance tasks, minimizing discrepancies and errors.

- Streamlined Workflow: Engineers and quality assurance teams can now rely on a consistent, electronic system that simplifies the tracking and updating of data.

Quantifiable impacts include:

- Between 25% and 50% FAI time savings:

The team can create FAIs in nearly half the time depending on the complexity of the drawings. - Accuracy up to 99%:

Thanks to the enhanced traceability and consistency provided by IDA, the team has significantly reduced rework.

Additionally, the user-friendly nature of DISCUS Software has made it easier for engineers to adapt, reducing the learning curve and resistance to change. This has fostered a more productive and positive working environment, ultimately contributing to PCC Airframe’s reputation for quality and reliability in the aerospace industry.

Overall, the implementation of DISCUS Software with IDA has been transformative for PCC Airframe, enabling the team to maintain high standards while improving operational efficiency. As Teter explains, “everything is way more streamlined” and there’s “a lot more consistency.” He looks forward to continuing the relationship with DISCUS Software, even leveraging his unique perspective to provide valuable insight and feedback for the DISCUS development team.

Top Features and Solutions for PCC Airframe

- Automated ballooning and data entry, reducing manual labor.

- Improved consistency across quality assurance processes.

- Customized spreadsheets that could be directly uploaded into customer systems.