H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Case Study

AeroFlexx needed a better way to make real-time data visible—and in a big way. By Seth Thompson

Visualizing Success:

How AeroFlexx Enhanced Converter Line Visibility

Case Study

H2 Deck Info By Paragraph Style Bold

Headline

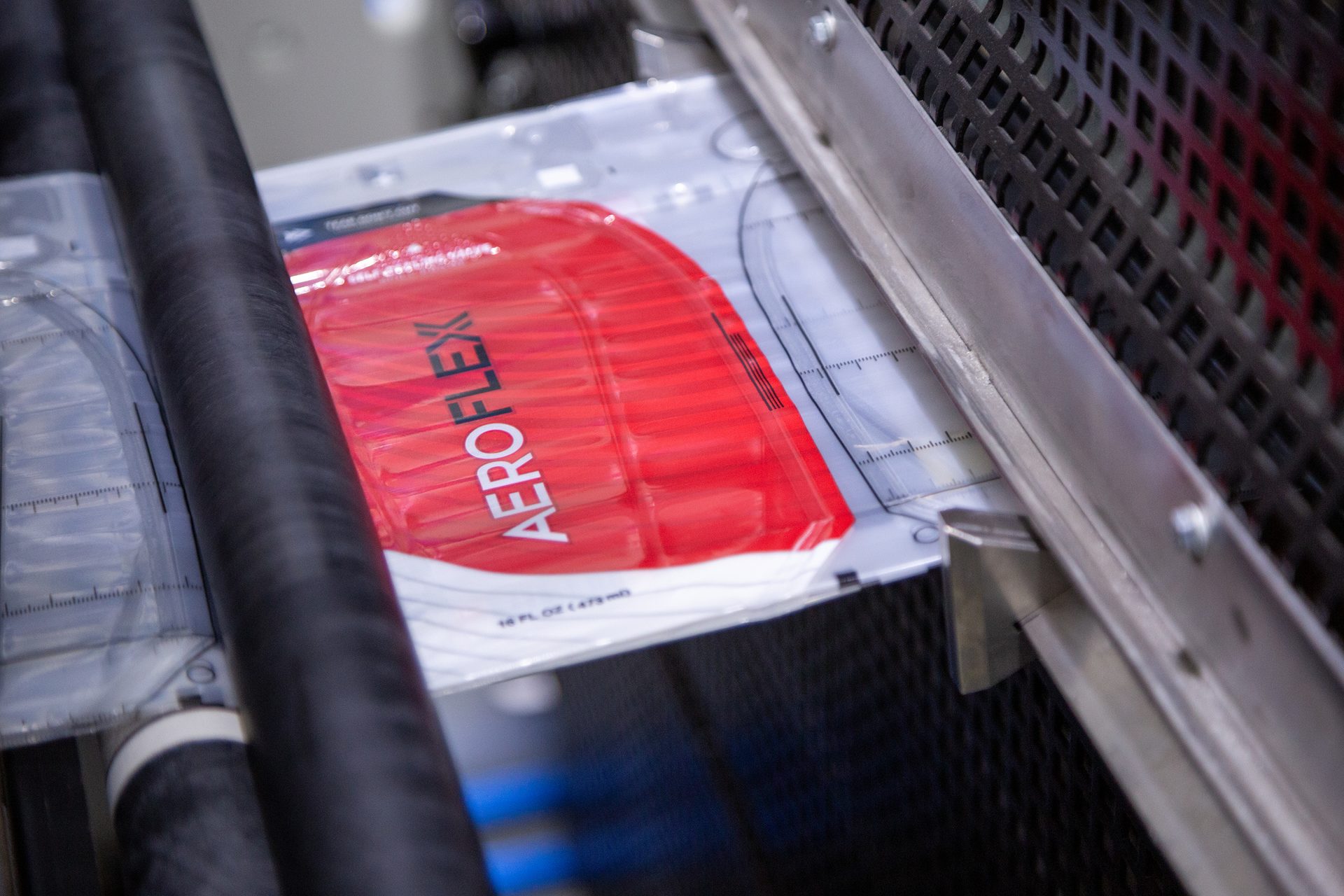

AeroFlexx, an innovative manufacturer of liquid packaging solutions, partnered with Factory Systems, a provider of smart manufacturing solutions, to solve a critical data visibility challenge on its high-speed converter line, dramatically improving operator insight, production tracking, and plant-wide communication.

AeroFlexx has built its reputation on disrupting traditional rigid packaging with its sustainable package that combines the best qualities of flexible and rigid bottles to create an entirely new format for liquid packaging. Central to its success is the converter line, a highly engineered system that shapes and seals each AeroFlexx Pak with precision.

As their process around the converter developed, they identified one crucial pain point. Operators needed to make on-the-fly adjustments to process parameters, but typical HMIs were too small, cluttered, and limited for high-speed decision-making. AeroFlexx needed a better way to make real-time data visible—and in a big way.

A Problem Hidden in Plain Sight

Despite the advanced automation behind AeroFlexx’s converter line, including top-of-the-line programmable logic controllers (PLCs) and integrated vision systems, much of the critical performance data remained locked inside the machine. HMI displays offered limited, localized views and weren’t designed to deliver broader insights to floor managers or plant leadership. At the beginning of the project, data was analyzed through data dumps and cellphone pictures of HMI screens. While some of these insights were actionable, the data was postmortem, leaving the production team unable to leverage proactive data monitoring insights before the end of production. Ultimately, AeroFlexx would need to find a way to see the production data in proactive and meaningful ways.

“It wasn’t that the data didn’t exist,” explained Mike Brentar, operations manager at AeroFlexx. “It was just siloed. We needed a way to liberate it from the line and make it accessible in real time everywhere.”

That’s when they turned to Factory Systems.

Caption

The FS.IoT Backbone

Factory Systems began by deploying its FS.IoT data aggregation solution, an edge-level platform that securely connects to industrial equipment like PLCs, sensors, and vision systems. With minimal disruption to the converter line, FS.IoT was configured to pull data points from:

- PLCs that were managing motion, temperature, distances, and sealing parameters

- The vision systems in place to perform real-time inspection and defect detection

Despite the complexity, the full integration was completed in just two weeks. During installation, Factory Systems provided on-site training, equipping AeroFlexx’s operators and engineers with the skills to use the new tools from day one.

This data was streamed to Factory Systems’ cloud-enabled web application, FS.Net, built on a SQL-based database. This normalized and timestamped all process metrics across the converter line. FS.IoT operated silently in the background, continuously collecting, storing, and preparing the data for visualization, in FS.Net without requiring changes to the existing control code. By hosting FS.Net on a leading cloud platform, AeroFlexx ensures secure, global access to real-time and historical plant data for operators on the floor and engineers halfway around the world.

From Data to Dashboards with FS.Display

Once FS.IoT had the data flowing into FS.Net, the data is displayed in FS.Display, a customizable dashboard application designed specifically for factory floor use. Built to run on low-cost streaming devices connected to standard televisions, FS.Display turned any device with a web browser in the facility into a potential dynamic operations board. With an easy to use browser-based configuration UI, AeroFlexx’s staff was able to easily implement their data philosophy in many customizable dashboards available to display at will.

Each dashboard was tailored to its location. Near the converter line, AeroFlexx’s operators viewed quality metrics, live status, defect rates, and material usage trends.

On-screen metrics included:

- CPK (Process Capability Index) for quality trends

- Total production counts for throughput monitoring

- In-spec vs. out-of-spec counts for real-time quality visibility

- Live charts of key measurements visually indicating their quality

In the office near the engineers pareto charts of downtimes along with their causes were added.

“The dashboards were a game-changer,” said Mike Brentar, AeroFlexx’s operations manager. “Everyone sees the same truth in real time. No more walking over to an HMI or pulling manual reports, it’s just there.”

Immediate Impact and Lasting Benefits

Within weeks of implementation, AeroFlexx noticed measurable improvements:

- Faster issue detection and resolution, thanks to real-time visibility

- Improved accountability across shifts, driven by transparent performance metrics

- Reduced downtime, as maintenance was able to respond proactively to emerging issues

The Chromecast-based solution proved remarkably scalable. As AeroFlexx expands its converter line capacity, new FS.Display dashboards are added simply by connecting another screen and assigning the relevant data views.

A Foundation for Smart Manufacturing

Beyond visualization, FS.IoT has positioned AeroFlexx to pursue broader Industry 4.0 initiatives. The centralized data lake now supports trend analysis, continuous improvement projects, and future integration with ERP and MES systems. The modular nature of the Factory System’s solutions coupled with the cloud-based platform enables wirelessly transmitting data even from machines anywhere to AeroFlexx’s system for visibility and analysis across the world.

What began as a pilot on one converter line quickly proved its value. Since this initial integration, AeroFlexx has expanded the solution to multiple production lines, including converters and fillers on a global scale.

“Implementing FS.IoT and FS.Display wasn’t just an upgrade, it was a strategic step forward,” said Veronica Sebald, vice president of quality at AeroFlexx. “With scalable data visibility and seamless cloud integration, we’re building a quality system designed to grow with our business, support predictive analytics, and enable smart manufacturing innovations well into the future.”

By combining the robust data collection capabilities of FS.IoT with the simplicity and flexibility of FS.Display, Factory Systems helped AeroFlexx turn hidden converter and filler line data into visible, actionable intelligence empowering operators, improving efficiency, and aligning the plant with its long-term production vision. As AeroFlexx expands, Factory Systems modular and scalable systems will grow alongside the flexible packaging manufacturer.