This Case Studies Special Advertising Section features manufacturing companies with real-world challenges using quality equipment, software and services to solve their problems and improve their processes. These problem-solving stories describe myriad manufacturing challenges and how the correct application of a supplier’s product or service made the difference, providing quantitative benefits to quality and manufacturing issues.

The suppliers in this special section present these real-world problems and solutions to help Quality Magazine subscribers who may have similar experiences.

Case Studies

— Special Advertising Section —

AngioDynamics uses GAGEtrak® for FDA Audit Success

Founded in 1988 in Queensbury, N.Y., AngioDynamics is a leader in the design, development and manufacturing of innovative therapeutic devices used for minimally invasive medical treatment and is selling in over 50 markets worldwide.

Prior to 2004, AngioDynamics’ Ben Gleason used Excel to manage his gages and calibrations and that worked fine for a while. However, when his responsibilities grew to tracking nearly 4,000 instruments and performing over 2,000 calibrations annually, he needed a more robust, secure system; that’s when he chose GAGEtrak.

Gleason is most impressed by GAGEtrak’s reporting features and FDA compliance. "It is so much easier to get a list of what is required at any given time and there’s a history of transactions for audits. Overall, [GAGEtrak is] a very good product. Pretty easy to use and the FDA has not been able to find fault with our process since we started using it."

Gleason also uses the GAGEtrak Calibration Label Kit to further streamline his workflow and when asked about his experience with the CyberMetrics support team, Gleason said, "Support has been absolutely fantastic! [The staff is] knowledgeable, courteous, patient and good-humored - a real pleasure to work with."

Making the leap from spreadsheets to GAGEtrak calibration management software was an easy choice for AngioDynamics and has proven invaluable for their FDA audits. It’s no surprise that GAGEtrak is consistently recommended by quality auditors. Contact us today to learn how GAGEtrak will do the same for your company.

From Motorsport to the Sky: Poggipolini’s Precision Power Takes Flight

PoggipoliniS.p.A., an Italian specialist in titanium and steel fasteners founded in 1950, spent three decades refining ultralight, high-strength hardware for motorsport giants like Porsche and Ferrari.

The company’s growth encountered a sharp challenge in 2009, when motorsport regulation changes slashed sales by 65%. Poggipolini strategically pivoted to aerospace in 2010, transferring its titanium and Inconel fastening expertise to aircraft applications. Within ten years, aerospace became its core business, now accounting for 60% of revenue by 2020.

Central to the firm’s aerospace success is its investment in advanced hot fast forging and precision measurement technologies. This process enables agile, cost-effective production of critical components—from drone assemblies to helicopter gearbox parts—even in small batches. Ensuring stringent compliance with aerospace quality standards, Poggipolini relies on a suite of ZEISS coordinate measuring machines, including PRISMO ultra, PRISMO, O‑INSPECT, and DuraMax systems.

Quality Manager Giacomo Michelini emphasizes that these systems allow automated measurements with unrivalled accuracy. CEO Stefano Poggipolini confirms that ZEISS technology has become integral to certifying every stage of production, meeting the exacting demands of aviation-grade safety and reliability. Their collaboration illustrates how agility, foresight, and precision-engineered inspection tools empowered Poggipolini to soar from racetracks to the skies—turning adversity into advantage.

Providing value creation guidance to NDE professionals worldwide to help them create and mature their own Use Cases for a Conformable DR Detector

Context of the solution

Radiographic image formation principles advise that, whenever feasible, the distance between the subject and the recording media, regardless of whether it is film, IPs, or DDAs, should be maintained as minimal as it is possible to minimize distortion and unsharpness effects on the resulting image.

This image formation principle is replicated in the radiographic inspection requirements contained within an ample spectrum of manufacturing and construction codes worldwide. Codes such as the ASME BPVC for boilers and pressure vessels or AWS D1.1/D1.1M in steel construction, specifications such as API 6A and standards such as ASME B31.1, ASME B31.3 or API 1104 have as a common trait that they embrace this imaging principle not only for the inspection of welds on pipes or tubular components, but also integrate it in the radiographic inspection requirements for castings, rolled products, forges, pipes, tubing, or other manufactured components formed with rounded surfaces.

Description of the initiative

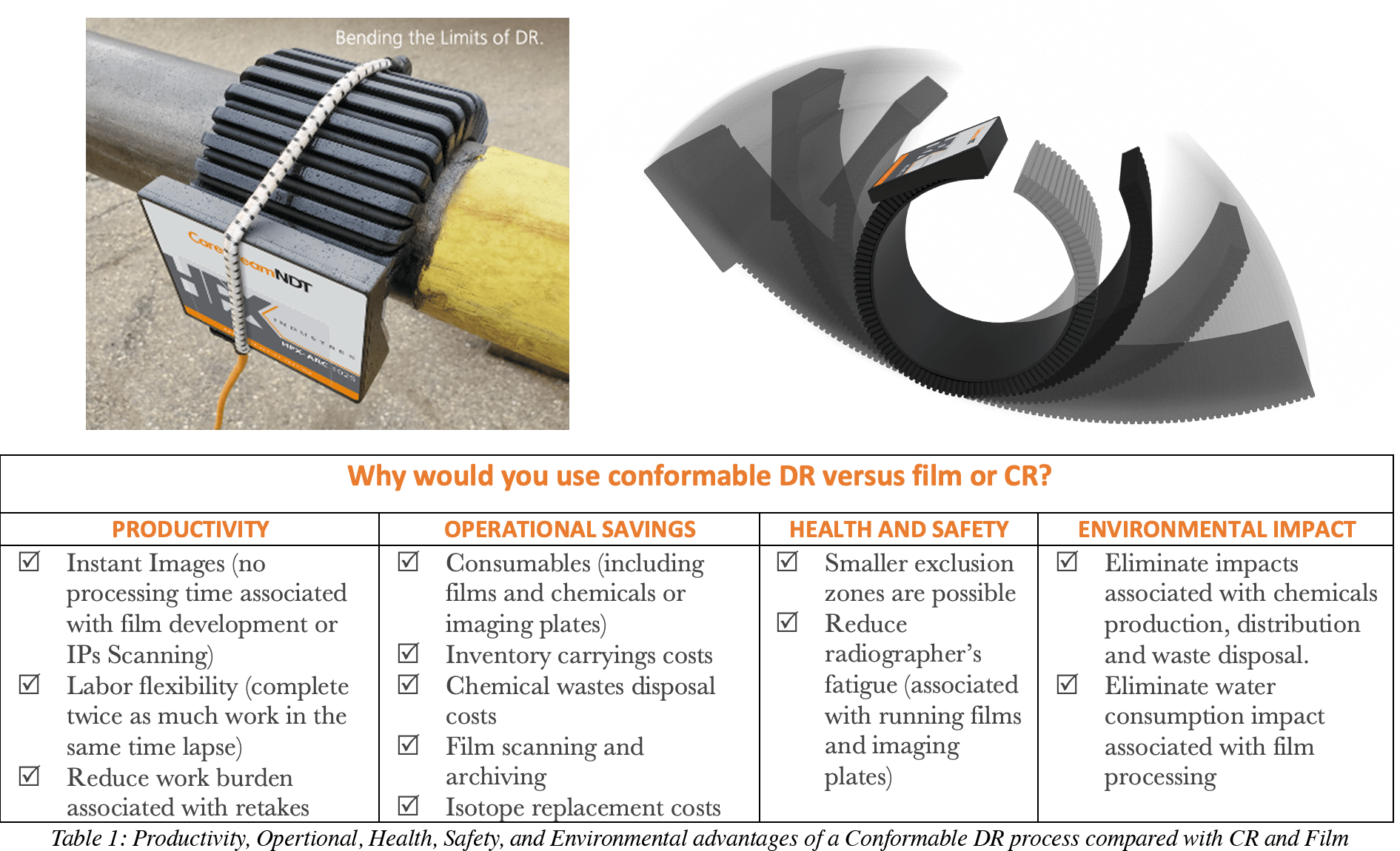

Bendable Digital Radiography Detectors constitute a new, exciting product category that delivers high-resolution images for these rounded components at game-changing speed and certainty in industries such as Oil & Gas, Energy Generation, Aerospace, Transportation, Military and Defense or NDE Services, which should capitalize on their inherent advantages as described in the following table:

In order to facilitate the creation of customized use cases for specific industries and imaging applications, Carestream NDT created a series of guidance documents that merge the hands-on field experience of its product specialists with the vast knowledge of its NDE imaging researchers.

Results Obtained - The Why’s, How’s and What’s

These guidance documents took the form of a series of three white papers with a profound strategic approach that adapts the structure of Simon Sinek’s Golden Circle:

Part I – “The Why’s”: Expanding, Enriching, and Reinforcing Your Imaging Capabilities

Part II – “The How’s”: Proposing an actionable approach to a new set of imaging capabilities

Part III – “The What’s”: An Instructive Comparison of Conformable DDAs to Film and CR Imaging Plates

This series of three whitepapers is available to download at our website.