Products

the latest products to help you improve your manufacturing process

FLIR ADGiLE Automated Methane Monitoring Solution

FLIR, part of Teledyne Technologies Incorporated, unveiled ADGiLE™, a fixed-mounted methane monitoring solution. Featuring optical gas imaging (OGI) with comprehensive edge detection analytics, ADGiLE is the oil and gas industry’s solution to meeting environmental stewardship and efficiency goals. The system, featuring a pan-tilt gas imaging camera, edge computing device, connectivity, and FLIR United VMS software within a ruggedized package, can help companies address the ever-evolving requirements for reducing methane gas leaks within oil and gas production, transmission, and storage infrastructure.

Designed for wide-scale site video monitoring and continuous leak detection applied to storage tanks, compressors, separators and many other equipment in the oil and gas industry, ADGiLE offers an industry-first, end-to-end fixed methane detection solution that leverages FLIR’s uncooled GF77a OGI technology, and is consequential to industry demands concerning methane mitigation.

FLIR ADGiLE pairs the GF77a with platform analytics processed at the edge to detect emissions through automatic early detection, quickly pinpointing the leak source. It provides the critical situational awareness on the emission event that isn’t possible with other methane detection technologies, such as satellite and aerial-based detection methods. Data is displayed via the FLIR United VMS software back at the control room, which can be configured with custom alerts, areas of interest, and pre-set imaging pathways for a truly automated experience.

The solution primarily focuses on midstream and high-concentration methane upstream applications. It works to detect and prevent high volume emission events, compared to FLIR’s existing cooled handheld OGI technology, leveraging FLIR’s unmatched edge detection analytics built upon decades of detection data and experience to deliver consistent, accurate results. The system increases both site efficiency and safety, as it operates equally well during the day and in total darkness at safe distances, pending atmospheric and site conditions.

“The industry knows FLIR as the world leader in handheld OGI detection, and now they can access lower cost technology via a completely automated, fixed solution with ADGiLE, featuring everything they need out of the box to quickly pinpoint and then fix large methane leaks,” said Craig O’Neill, Business Development Director, FLIR. “ADGiLE is purpose-built for mid- and upstream methane operations to deliver game-changing results to achieve methane mitigation demands along with internal emission reduction goals. This makes ADGiLE a market leading solution for well site operators, compressor stations, and storage facilities that must invest in methane detection and monitoring technologies.”

FLIR ADGiLE uniquely meets the most serious methane leak detection challenges while providing operational insight to understand emissions that are a part of routine industry processes versus fugitive emission events. The system can also help prevent false readings, saving time and resources by avoiding the need to manually investigate and confirm specific leaks. At the same time, it can still detect intermittent leaks that happen and are too often missed by deployed aerial detection technologies using a wider temporal frequency. It can generate situational awareness that addresses the full range of challenges stemming from various methane emission scenarios.

INFICON Helium Leak Detection

Leak tests are essential in semiconductor factories and in the manufacture of solar cells and flat panel displays. Identifying the smallest leaks with helium leak detection is important for maintaining the required purity, avoiding defects and ultimately for product quality. To enhance the UL family of leak testers, INFICON has therefore launched the three intelligent additions SMART-Spray, I·BOOST and SPRAY-Check. The specialist in measurement technology, sensor technology and control software thus ensures easier handling, faster response times, shorter test cycles and more reliable measurement results.

INFICON is offering a new helium spray gun with the SMART-Spray. The hose-bound handling of large helium cylinders and the error-prone adjustment of the spray volume are a thing of the past with SMART-Spray. "The handy device, which is designed for over 1,000 sprays per helium filling, replaces a remote control and combines its functions with those of a manual helium spray gun," says Product Manager Markus Schwambera, summarising the advantages. Equipped with an illuminated colour display, it makes leak detection on complex semiconductor systems with many test points and potential leaks easier. These applications are characterised by limit leak rates of less than 1 x 10-9 mbar x l/s. In these applications, the battery-operated, portable device makes leak testing more flexible, simpler and more efficient.

With the signal processing filter I·BOOST software update, INFICON accelerates the leak rate signal. This shortens the response and test times, especially for the UL3000 Fab and UL6000 Fab series, because the test points can be sprayed at shorter intervals. "The bottom line is that this results in a time saving up to 50 % in leak detection in all measuring ranges," says Product Manager Markus Schwambera, outlining the leap in efficiency. "Users who purchase the licence achieve faster and more precise measurement results for different chamber volumes," assures Schwambera. The benefits of I·BOOST are also particularly effective in complex semiconductor systems. "The lower the limit leakage rates, the longer the test cycles usually take – and this is where the higher sensitivity and time savings of I·BOOST have the greatest impact," argues Schwambera.

With the SPRAY-Check, INFICON offers an easy-to-install test leak. "The tool is based on quartz windows that are only permeable to light gases such as helium and hydrogen. This increases safety and extends the functionality of leak detection," explains Markus Schwambera. SPRAY-Check allows the measurement set-up and test method to be checked in the relevant leak rate range. It can also be attached directly to the system to carry out dead-time checks. "Sometimes a certain amount of time elapses between the spray shot and the indication on the display," says Schwambera. This allows users to better estimate how long the pause between spraying points should last so that potential leaks can be clearly assigned. The exclusion procedure applies: If there is no indication after the dead time has elapsed, there is no leak. "Because SPRAY-Check is impermeable to gases that are harmful to the process, such as water or oxygen, it can also remain mounted on the semiconductor system," explains the product manager. Important areas of application are systems with limit leakage rates below 10-9 mbar x l/s.

SMART-Spray, I·BOOST and SPRAY-Check are suitable for all mobile INFICON helium leak detectors of the UL family, whereby I·BOOST is limited to the latest generation of UL devices (UL3000 Fab/UL6000 Fab series). The UL6000 Fab is the most powerful and best device on the market for larger test volumes in modern semiconductor factories and coating systems with very large chamber volumes. It offers the fastest response times and shortest test times in all measuring ranges. Its compact design makes it easy to maneuver even in tight spaces. The UL3000 Fab series was also developed for leak detection in semiconductor factories. "It is characterized by flexibility, mobility, fast commissioning and high sensitivity. Users also receive their precise test results very quickly and are the standard in modern semiconductor factories," emphasizes Product Manager Schwambera. The UL3000 Fab also requires only a small footprint and can be easily and maneuvered through narrow spaces. The UL1000 Fab series covers a wide range of applications when it comes to economical helium vacuum leak tests in industrial or semiconductor environments - especially for smaller chamber volumes. The main advantages: The device is very powerful, robust and inexpensive to purchase.

DÜRR NDT Portable Digital X-ray Detectors

With the new D-DR series of robust flat panel detectors for industrial radiography, DÜRR NDT aims to continue to offer the best possible DR technology. This new product line has a uniform and functional design and covers a wide range of RT applications.

The basic spatial resolution (SRb) is at the highest possible: 80 µm for the small and medium detectors and 100 µm for the bendable and large detectors. Due to weights ranging from 2 to 6 kg, the detectors are among the lightest in their class and are easy to handle.

Further advantages of the D-DR series are long battery runtime, hot-swap functionality and IP 67 protection class. In addition to wireless operation, all detectors can also be operated by wired data transmission and power supply.

The D-DR 1025B detector has an innovative bending mechanism and due to its high resolution is perfectly suited for testing circumferential weld seams in accordance with DIN EN ISO 17636-2 (Class B).

Thanks to the integrated shielding, the detectors are suitable for X-ray sources up to 450 kV and depending on the model, for gamma sources, with a maximum frame time of 180 seconds.

Like all digital X-ray systems from DÜRR NDT, the D-DR detectors are used with D-Tect X inspection software. Special functions such as multi-gain calibration ensure the highest possible image quality. Powerful and intelligent tools, such as one-click wall thickness analysis and image optimization filters, make image evaluation simple and efficient.

DÜRR NDT

https://www.duerr-ndt.com

Instron Autoinjector Testing System

Instron announced the release of the next generation Autoinjector Testing System for full functionality testing of pen and autoinjectors to ISO 11608. Developed in close partnership with pharmaceutical companies and CDMOs, this system measures a variety of essential performance requirements, including cap removal, dose accuracy, activation force, injection time, needle depth, and needle guard lockout.

The ability to perform a complete sequence of tests on one system, rather than multiple systems, simplifies testing, data consolidation, and the validation process, and streamlines tech transfer to production sites.

The addition of simple autoinjector test methods to Instron’s Bluehill Universal software empowers users to easily develop and change test methods. The user simply selects which tests (cap removal, injection, and/or needle guard lock out check or defeat force) are to be run and sets the desired parameters. The system then automatically runs through the test sequence and provides results including cap removal and activation forces, injection time, needle depth measurements at the start and end of injection, click detection, delivered volume, and safety check results.

Bluehill Universal for autoinjectors also improves compliance with Good Manufacturing Practices (GMP) by integrating system suitability testing (SST) into its workflow. SST prompts users to perform daily verification checks on the load cell, machine vision camera, and scale. The system only allows device testing to proceed once these checks have been successfully completed. SST details are recorded in the Traceability module’s audit log, offering a robust and searchable record.

To simplify tech transfer, Instron’s Bluehill Central lab management software can be added to streamline management and transfer of both device and SST test methods between testing systems in the same lab and other sites around the world.

Instron also offers services, including on-site calibrations and IQOQ services, to help testing labs accelerate their validation process.

Instron

www.instron.com

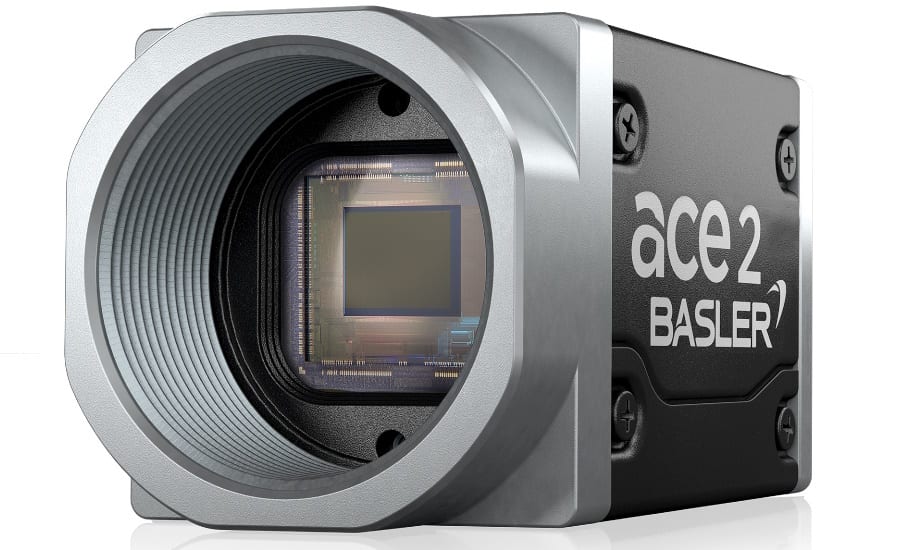

Basler High-Resolution ace 2 X visSWIR Cameras

With the new ace 2 X visSWIR models, Basler AG presents compact, cost-effective SWIR cameras with high resolutions and excellent image quality. The international manufacturer of high-quality machine vision hardware and software also offers all relevant components for SWIR vision systems.

Basler AG is expanding its ace 2 X visSWIR camera family with four high-resolution models. The models (optionally with USB 3.0 or GigE interface) are equipped with Sony's latest SenSWIR sensors IMX992 and IMX993 with 5 MP and 3 MP resolution. They complement the models already available with the IMX990 (1.3 MP) and IMX991 (VGA) sensors. Thanks to firmware features, all SWIR cameras deliver high image quality in the visible and short-wave infrared spectrum, from 0.4 µm to 1.7 µm. With a design of 29 mm x 29 mm, they are compact and also inexpensive, making them suitable for applications for which conventional SWIR cameras are too large or too expensive.

Thanks to innovative firmware features, Basler is able to dispense with cooling for the ace 2 X visSWIR cameras and still offer high image quality in a small size at an attractive price.

The Pixel Correction Beyond feature detects the pixel defects typical of InGaAs sensors in every image during use. It then corrects them in real time directly in the camera without distorting the image content. The Line Noise Reduction feature, implemented in SWIR cameras with the already established IMX990 and IMX991 sensors, reduces the background noise typical of these sensors in the form of horizontal bars in the image and ensures a more homogeneous image background.

In addition to the cameras, Basler provides a comprehensive range of visSWIR accessories, including special SWIR lenses, illumination, and filters. Matching PC cards and the proven pylon software for image acquisition complete the portfolio, allowing a complete visSWIR vision system to be set up from a single source.

"SWIR cameras with InGaAs sensors are often equipped with cooling to counteract pixel defects. However, this has a detrimental effect on the size and price of the cameras. All our visSWIR cameras, including the new high-resolution models, do not require cooling. The firmware features, in particular the dynamic defect pixel correction (Pixel Correction Beyond), enable us to offer the cameras in a compact design at an attractive price," emphasizes Dr. Melanie Gräsel, Product Manager at Basler.

Basler AG

www.baslerweb.com