The most powerful tool a company has is the ability to follow a component failure back to the batch of material it was made from. By Casey Willis

Important Considerations for

Tensile Testing

Equipment in Aerospace Applications

Test & INspection

The most powerful tool a company has is the ability to follow a component failure back to the batch of material it was made from. By Casey Willis

Test & INspection

H2 - Deck info goes here

By Paragraph Style Bolded

The aerospace materials market is growing rapidly, with an expected CAGR of 8.8% from 2021 to 2026¹. As material production ramps up, the demand for tensile testing will increase in every segment of the market, from the OEM level to the tier three suppliers. With demand rising for aerospace products, material testing companies are challenged to match the developmental pace of the industry.

To prepare for the coming boom in the aerospace industry, companies are urgently reskilling large sections of their workforce to fill the demands of the materials market. Because aerospace materials are subject to extremely harsh conditions, they also have some of the most meticulous testing requirements, meaning that starting a test lab or qualifying a new piece of equipment is a significant undertaking. Therefore, whether you are an OEM testing an airframe or a third tier supplier testing high strength alloys, it is crucial to use a reliable tensile testing system that can produce repeatable results.

Nadcap and Other Standards

The National Aerospace Defense Contractors Accreditation Program, or Nadcap, is an industry-wide program that assures laboratory conformity in the aerospace industry. When purchasing a tensile tester it is crucial to ensure that there is a service organization in your area accredited to ISO 17025 by NVLAP to perform calibrations and accreditations. ISO 17025 is pivotal to ensuring traceable audits of laboratory equipment, which in turn verifies the quality and integrity of the results. Tensile testers that are being used for an aerospace application should be put on a regular calibration schedule in order to ensure the accuracy of the strain, speed, displacement, and force readings of the equipment.

Contracting Out Testing

Testing is occasionally contracted out to Nadcap compliant test labs. This is a convenient solution for labs where test volume is low, or if the lab lacks equipment to perform the test. The cost of contracting out testing is dependent on the number of specimens that are being tested and the complexity of the test. The turnaround time can be quick, though the additional lead time of shipping needs to be factored in. Contracting testing is something high-throughput laboratories want to avoid due to the cumulative financial and logistical costs. However, if in-house testing is adopted, it is important that the test systems be proactively maintained in order to avoid costly system downtime. Many tensile testing companies offer modernizations or retrofit packages that will extend the lifetime of your equipment by replacing the at-risk components of your frame.

Picking the Right Tensile Tester

When introducing a new piece of equipment to your lab it is important to evaluate all available options. In addition to establishing your required testing capacity and fixturing, it is also important to ensure that the system you choose is designed to be robust, with high stiffness. Another thing to consider is the nature of the material that you plan to test and how your material might affect the testing system. For example, if you are testing carbon fiber specimens in tension, small particles will be expelled during break, which can be damaging to the system’s electronics. Therefore, the system should be designed in such a way as to keep debris away from its sensitive hardware. If your lab is planning on testing at the higher end of the system’s capacity, ask your supplier how they combat shock loads. If your lab is going to do high throughput temperature tensile testing, consider purchasing two systems or a dual-mounted furnace setup. It may take up to an hour for a specimen to get up to temperature, so having the ability to soak one specimen while testing another can save your lab valuable time. Additionally, purchasing dual furnaces is more cost effective than buying a second system.

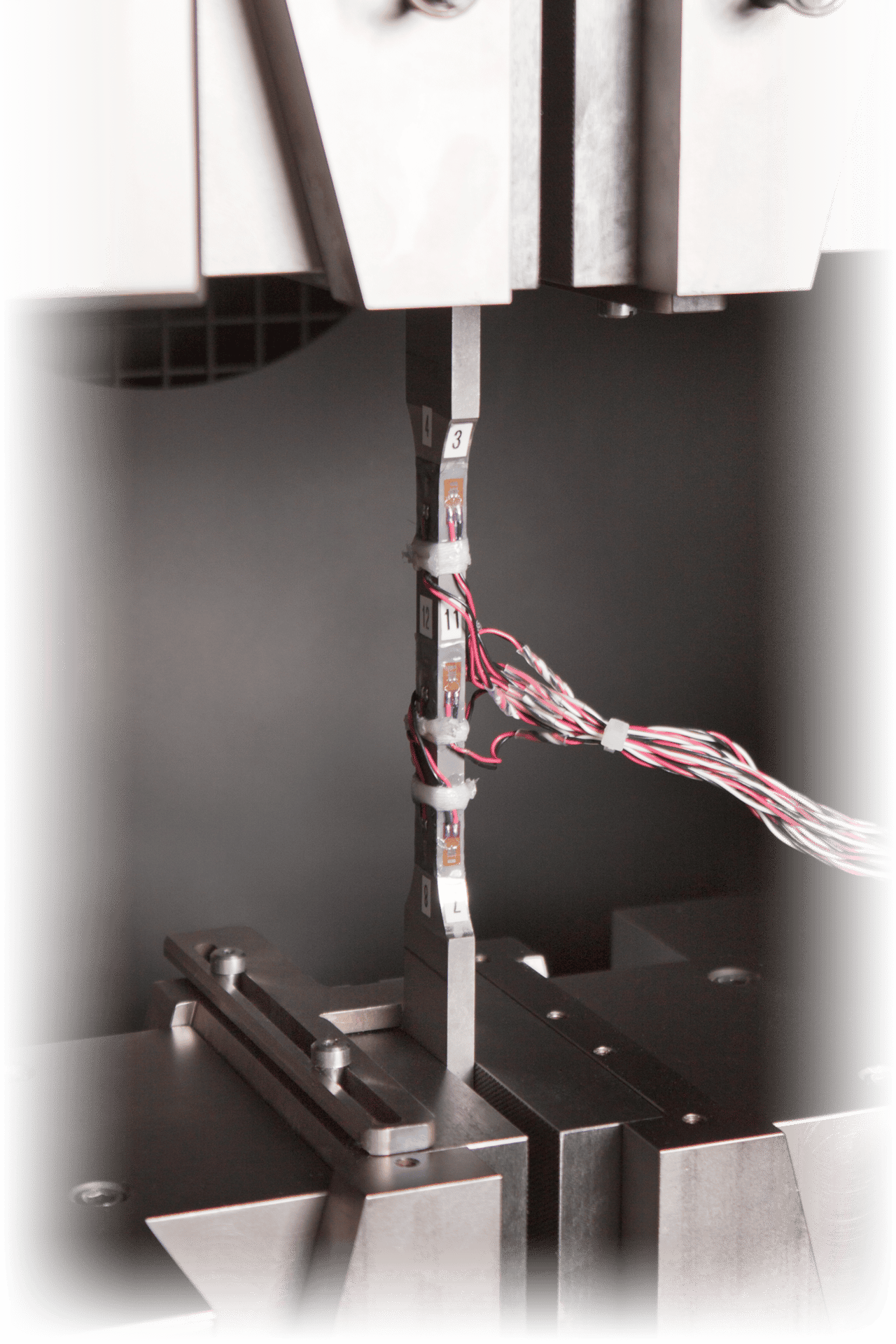

Materials testing companies will highlight the load string configurations that they offer in accordance with Nadcap. These will likely include their most compliant grips and fixtures. Commonly recommended grips have a moving body design with a high stiffness; these grips have jaw faces that clamp onto the specimen horizontally, which makes it easier to guide the specimen into place and reduces variability. Grips should also be symmetrical, because an asymmetrical grip is more likely to deform under load affecting testing results. Another recommended accessory is specimen stops, which ensure the specimen is sitting in the grips at the same spot in every test.

Verifying that your load string is set up to minimize bending is key to getting accurate and repeatable data. If the bending strain falls outside the allowable limit, the load string will need to be adjusted. This can be done manually by making tweaks to load string attachment points (e.g. loosening, tightening, adding shims, etc.). This is a method of trial and error until the data falls within the allowable limits. Manufacturers of tensile testers have identified this issue and provided a simple solution: an alignment kit can be added which allows fine adjustments to the angular and axial direction of the load string. Pairing this kit with a strain gaged specimen provides live read-outs of the bending strain.

Traceability is Key

When the end use for a material is a commercial application, it is imperative that no box is left unchecked in terms of data reliability and security. From the moment a raw material is produced to its integration into an aircraft, all steps in its development process need to be tracked, meaning that both internal and external audits of these organizations are critical. To be prepared for an audit, keep documentation of the calibrations of your tensile testing system. Many service organizations can produce this documentation for you as evidence of compliance.

The most powerful tool a company has is the ability to follow a component failure back to the batch of material it was made from, and keeping documentation of changes is a part of every audit. The advancement of testing software technology has made it easy for highly regulated industries to leave a clear audit trail. Modern testing software is a powerful tool for traceability and allows lab managers to have full administrative control over their operators’ access. Operator profiles can be configured to restrict users from changing methods if the administrator so chooses, preventing unwanted changes that might bring your testing out of compliance. If it is necessary to grant operators access to change methods, any changes can be saved in an event log. This revision history can be referenced to ensure that a person with the proper training is making accurate and approved changes. Revision history should include the time and date of the change, the user who made the change, the value saved, and a record of the old value. In some scenarios, labs require any changes that are made to be signed off on by another user, such as the lab manager. It is now possible to track those electronic signatures with testing software, allowing labs to verify that any changes were reviewed before being implemented.

As the aerospace industry continues to expand, advancements in materials testing technology allow laboratories to keep up with this increased demand. Innovations in system design and testing software allow for more efficient and secure testing as volume increases. The key to the success of your program is choosing a solutions provider who can not only provide you with the most appropriate testing equipment for your specific needs but can also partner with you to achieve and maintain Nadcap accreditation status in order to ensure you meet your testing goals.