Products

the latest products to help you improve your manufacturing process

JAI Go-X Series Cameras

JAI announced an expansion of the Go-X Series of small machine vision cameras to include 24 new global shutter camera models featuring the latest Sony Pregius S CMOS sensors. The additional models are divided into two interface groups, with 12 models having CoaXPress 2.0 interfaces and 12 models having GigE Vision (1000BASE-T) interfaces. 12 additional Go-X Series cameras featuring GigE Vision interfaces operating at 5GBASE-T speeds are planned for later this year.

Pregius S sensors feature backside illumination to support smaller pixel sizes without sacrificing sensitivity. JAI has leveraged this technology to provide customers with significantly higher resolution options while still maintaining the compact size of the Go-X Series cameras. While the Go-X Series previously offered resolutions ranging from 2.3 megapixels to 12.3 megapixels, the additional models now extend that range up to 24.5 megapixels. Yet thanks to the 2.74 µm pixel size, even the new 24.5-megapixel Go-X Series cameras have the same 29 mm x 29 mm size as the other models and a 1.2" optical format compatible with C-mount lenses. Camera lengths vary from 51.5 mm to 55 mm depending on the interface.

The specific resolutions of the new cameras are:

- 5.1 megapixels (2472 x 2064 pixels)

- 8.1 megapixels (2856 x 2848 pixels)

- 12.4 megapixels (4128 x 3008 pixels)

- 16.2 megapixels (5328 x 3040 pixels)

- 20.3 megapixels (4512 x 4512 pixels)

- 24.5 megapixels (5328 x 4608 pixels)

Monochrome and color models with two different interfaces are offered at each resolution. Color models provide raw Bayer output and include an in-camera debayering function for RGB output. Formats include 8/10/12-bit monochrome, 8/10/12-bit Bayer, or 24/30/36-bit RGB output.

The 12 models with CoaXPress interfaces add a third interface option to the Go-X Series, which previously offered cameras with either GigE Vision or USB3 Vision interfaces. These CoaXPress cameras are designed for applications requiring increased performance in terms of resolution and frame rate, while still maintaining a small body size and price. They are equipped with a single CXP-6 connector providing 6.25 Gbps of bandwidth and speeds ranging from 24 fps for 24.5-megapixel output, up to 112 fps for the 5.1-megapixel models.

The 12 new GigE Vision models offer the networking capabilities and the grabber-less connections that have made this interface standard so popular in the machine vision industry. They operate at speeds from 4 fps for 24.5-megapixel output to 23 fps for 5.1 megapixels, as dictated by the 1 Gbps limit of the interface. For customers wanting the convenience and flexibility of the GigE Vision standard, but needing higher frame rates, JAI has included a lossless compression function called "Xpress" in the new GigE Vision monochrome models. The Xpress compression algorithm encodes redundant image information to reduce the size of the data being output from the camera while enabling it to be fully reconstructed by software running on the host processor. The amount of compression that can be achieved varies depending on the scene, but size reductions of 30% are common. Such reductions can generate frame rate increases of 40% or more or can be used to allow more cameras to share limited bandwidth.

Both the CoaXPress models and the GigE Vision models can accept power and triggering over the interface or via a separate 6-pin connector.

All of the new models also include a flexible, sub-pixel scaling function called "Xscale." Xscale provides an alternative to traditional binning which is limited to "whole" pixels, such as 2x1, 2x2, 4x4, etc. Instead, Xscale, supports the use of floating-point numbers to create “virtual” pixels that include fractional portions of pixels to help match pixel sizes, optical formats, and resolutions when replacing older cameras. In addition, while traditional binning can only be used on monochrome cameras, Xscale can be used with monochrome, Bayer, or RGB formats. Xscale can independently scale in the horizontal and vertical directions and can scale up to 16x the 2.74 µm base pixel size of the new cameras.

The new cameras join the 24 existing Go-X Series GigE Vision and USB3 Vision cameras to bring the total size of the series up to 48 models. All Go-X cameras feature high shock and vibration ratings of 80G and 10G, respectively, and are designed to optimally dissipate heat to avoid breakdowns in typical industrial environments and under non-stop operating conditions. Like the original models, the new models carry a six-year warranty.

JAI

www.jai.com

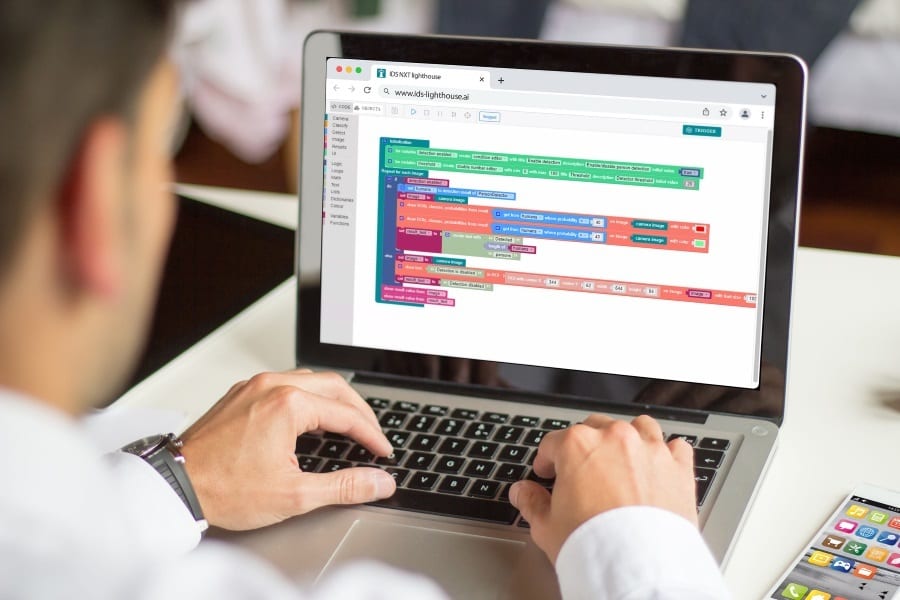

IDS NXT “App Your Camera!” Themed Software

The current software release 2.6 for the AI vision system IDS NXT focuses primarily on simplifying app creation. The initial phase in development is often one of the greatest challenges in the realization of a project. With the help of the new Application Assistant in IDS NXT lighthouse, users configure a complete vision app under guidance in just a few steps, which they can then run directly on an IDS NXT camera. With the Block-based Editor, which is also new, users can configure their own program sequences with AI image processing functions, such as object recognition or classification, without any programming knowledge.

Users create simple sequences in a few minutes with this visual code editor without having to know the syntax of a specific programming language. With the Use Case Assistant, IDS supports users in creating Vision App projects. They simply select the use case that fits their project. With queries and tips, the assistant guides them through the process of creating the Vision App project and creates the code, just like in an interview. It links existing training projects with the vision app project or creates new training projects and data sets in IDS NXT lighthouse if required.

With the combinable blocks and the intuitive user interface of the Block-based Editor, anyone can realize their own projects using AI-based image processing (such as object detection or classification) as an individual vision app without having to know the syntax of a specific programming language. Using the predefined blocks of the code editor, users build their vision app graphically, including processes such as loops and conditional statements.

How this works is demonstrated, for example, in the IDS Vision Channel (www.ids-vision-channel.tech). The session "Build AI vision apps without coding – xciting new easyness" is available for viewing as a recording.

IDS NXT is a comprehensive system with a wide range of workflows and tools for realizing your own AI vision applications. The intelligent IDS NXT cameras can process tasks "OnDevice" and deliver image processing results themselves. The tasks of the cameras are determined by apps that are uploaded to the cameras and executed there. Their functionality can thus be changed at any time. This is supported by software such as IDS NXT lighthouse, with which users can not only train neural networks, but now also create their own vision apps. The system offers both beginners and professionals enormous scope for designing AI vision apps.

IDS NXT

www.ids-nxt.com

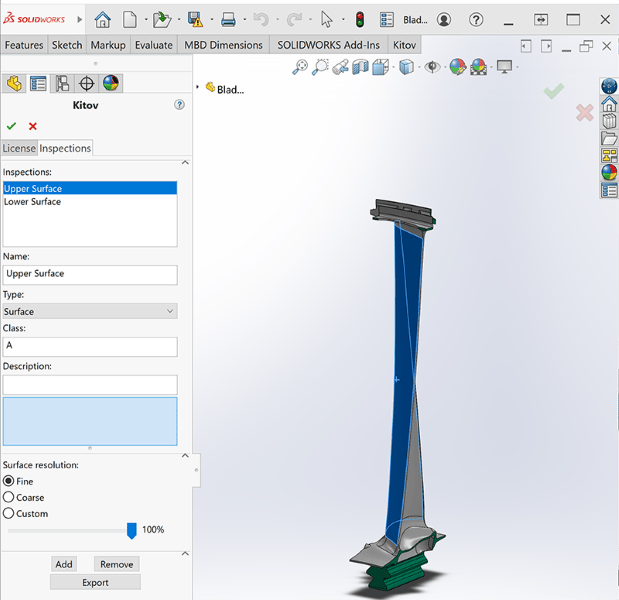

Kitov.ai CAD2SCAN Automated Inspection Planning Tool

Israel-based smart visual inspection company Kitov.ai has significantly simplified the setup of robotic vision inspection systems with CAD2SCAN, a CAD-based automated inspection planning tool.

CAD2SCAN is the latest feature of the Kitov Smart Planner. By combining CAD2SCAN with Kitov’s smart visual inspection and Review Station, customers can automate inspection solutions that are too difficult and time-consuming to manually program and deploy.

The planner captures multiple inspection points in a single image when possible, reducing the cycle time.

Semantic information extracted from the CAD is passed on to Kitov semantic detectors, which use the information for better inspection. For example, in surface inspection, information on material properties, such as surface reflectance, is used to determine the best illumination angles. Information on screw type and dimensions can enhance screw inspection. Other Kitov semantic detectors, such as labels, barcodes, and connectors, benefit from the relevant semantic information extracted from the CAD model.

Automatic CAD-based inspection planning is a game-changer for industries that manufacture complex parts and products. For example, CAD2SCAN technology improves the inspection of single-material parts with complex 3D geometric shapes, such as turbine engines, blades, wheels, and metal molding; CNC parts, where it is very hard and time-consuming to carry out full inspection manually; and custom-made or other low-volume parts (such as medical implants or 3D-printed parts), where it is extremely hard and not economical to automate inspection in any other way.

CAD2SCAN technology is implemented as a plugin to common CAD software systems (currently available for SolidWorks and Creo). It also supports the evolving QIF (quality information framework) ISO standard and can parse visual inspection requirements embedded into it.

Kitov.ai

www.kitov.ai

Cal Test Electronics CT4432 High-Voltage Oscilloscope Probe

Cal Test Electronics introduces the CT4432 High-Voltage Oscilloscope Probe. The CT4432 has a 10 kV maximum voltage input rating and is cTUVus listed.

The CT4432 High-Voltage Probe features:

- Bandwidth of 40 MHz 1

- Up to 10 kV input (DC + ACpeak)

- cTUVus safety certified

- Improved dual-resistor design

- Attenuation factor of 1000x

- Compensation range of 5 pF - 50 pF

- Replaceable tips

- Insulated BNC connection

- Can be used with your DMM by employing BNC Converter CT3197B

- RoHS 2 Compliant

- Two-year warranty

Because an oscilloscope has limits to the input voltage it can accept, measuring higher voltages may sometimes require the use of an attenuating high-voltage probe. The CT4432, with an improved dual-resistor design, can accurately and safely step-down higher voltages to an acceptable level. It offers 1000x attenuation and features a compensation range of 5 pF to 50 pF for a wide range of oscilloscope capacitance matching.

The CT4432 High-Voltage Oscilloscope Probe enables you to safely measure voltage levels up to 10 kV. With the Cal Test Electronics name and certification by cTUVus, you can be confident this test accessory is both reliable and safe. The CT4432 is covered by a two-year warranty.

This probe is compatible with oscilloscopes (of 1 MΩ input) from all major manufacturers.

The CT4432 High-Voltage Probe is ideal for:

- High-Voltage non-category rated measurements

- Lab environments

- Extended bandwidth measurements 1

1 Please note: Max voltage decreases as frequency increases

Cal Test Electronics

https://www.caltestelectronics.com/