This Case Studies Special Advertising Section features manufacturing companies with real-world challenges using quality equipment, software and services to solve their problems and improve their processes. These problem-solving stories describe myriad manufacturing challenges and how the correct application of a supplier’s product or service made the difference, providing quantitative benefits to quality and manufacturing issues.

The suppliers in this special section present these real-world problems and solutions to help Quality Magazine subscribers who may have similar experiences.

Case Studies

— Special Advertising Section —

AngioDynamics uses GAGEtrak® for FDA Audit Success

Founded in 1988 in Queensbury, N.Y., AngioDynamics is a leader in the design, development and manufacturing of innovative therapeutic devices used for minimally invasive medical treatment and is selling in over 50 markets worldwide.

Prior to 2004, AngioDynamics’ Ben Gleason used Excel to manage his gages and calibrations and that worked fine for a while. However, when his responsibilities grew to tracking nearly 4,000 instruments and performing over 2,000 calibrations annually, he needed a more robust, secure system; that’s when he chose GAGEtrak.

Gleason is most impressed by GAGEtrak’s reporting features and FDA compliance. "It is so much easier to get a list of what is required at any given time and there’s a history of transactions for audits. Overall, [GAGEtrak is] a very good product. Pretty easy to use and the FDA has not been able to find fault with our process since we started using it."

Gleason also uses the GAGEtrak Calibration Label Kit to further streamline his workflow and when asked about his experience with the CyberMetrics support team, Gleason said, "Support has been absolutely fantastic! [The staff is] knowledgeable, courteous, patient and good-humored - a real pleasure to work with."

Making the leap from spreadsheets to GAGEtrak calibration management software was an easy choice for AngioDynamics and has proven invaluable for their FDA audits. It’s no surprise that GAGEtrak is consistently recommended by quality auditors. Contact CyberMetrics today to learn how GAGEtrak will do the same for your company.

1-800-777-7020

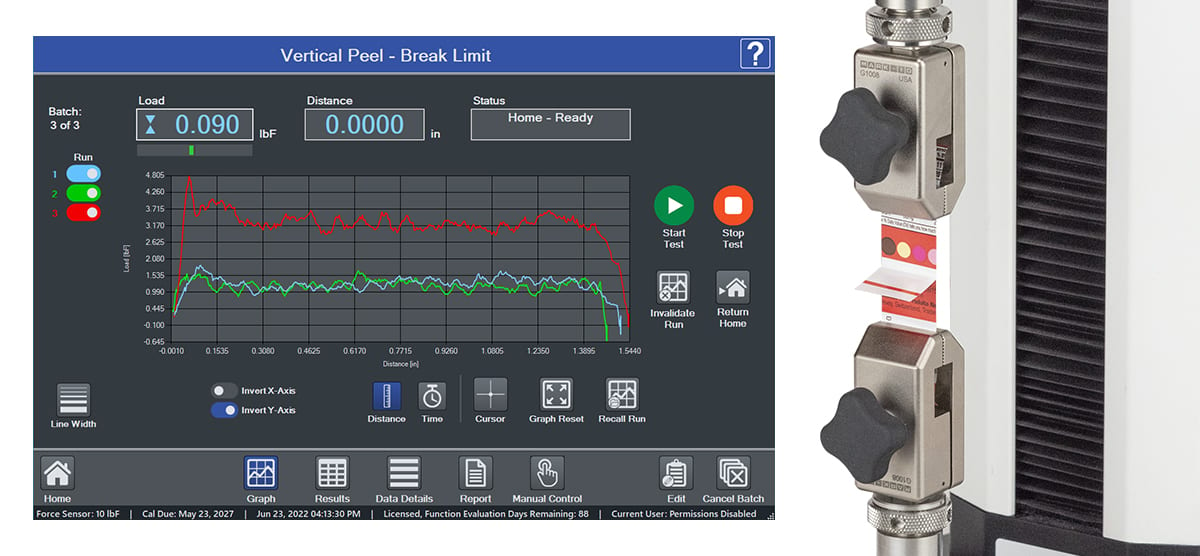

T-Peel Testing for Food Packaging Quality Assurance

A snack food manufacturer needed to test seal strength to ensure package integrity and ease of opening.

After consulting with Mark-10 product specialists, it was determined that a vertical T-peel test (ASTM D1876) would be used to test the average peel strength, minimum, and maximum peeling loads for each sample. A T-peel test was the best fit for this application because the adhesive bond was between two flexible pieces of packaging material.

Samples were prepared by cutting the packaging material into 1" wide strips with 3/4" of adhesive bond area. The samples were attached to an F305 Advanced Test Frame with a 10 lbF capacity force sensor and pair of film and paper grips.

A break limit test was configured in the system’s integrated IntelliMESUR® control panel, which would test batches of five samples and return the average peel strength, minimum, and maximum peeling loads for each sample. Pass/fail limits were set to ensure that any sample requiring an excessive amount of force to peel would be marked as failing. Similarly, insufficient forces were predictive of premature opening during transportation, potentially exposing the product to the elements.

By adding this test procedure to their quality assurance workflow, the manufacturer was able to start collecting data for a variety of seals used in their packaging. This data was then used to set a standard for seal characteristics and to ensure that all packaging was both secure and easy to open.

631-842-9200

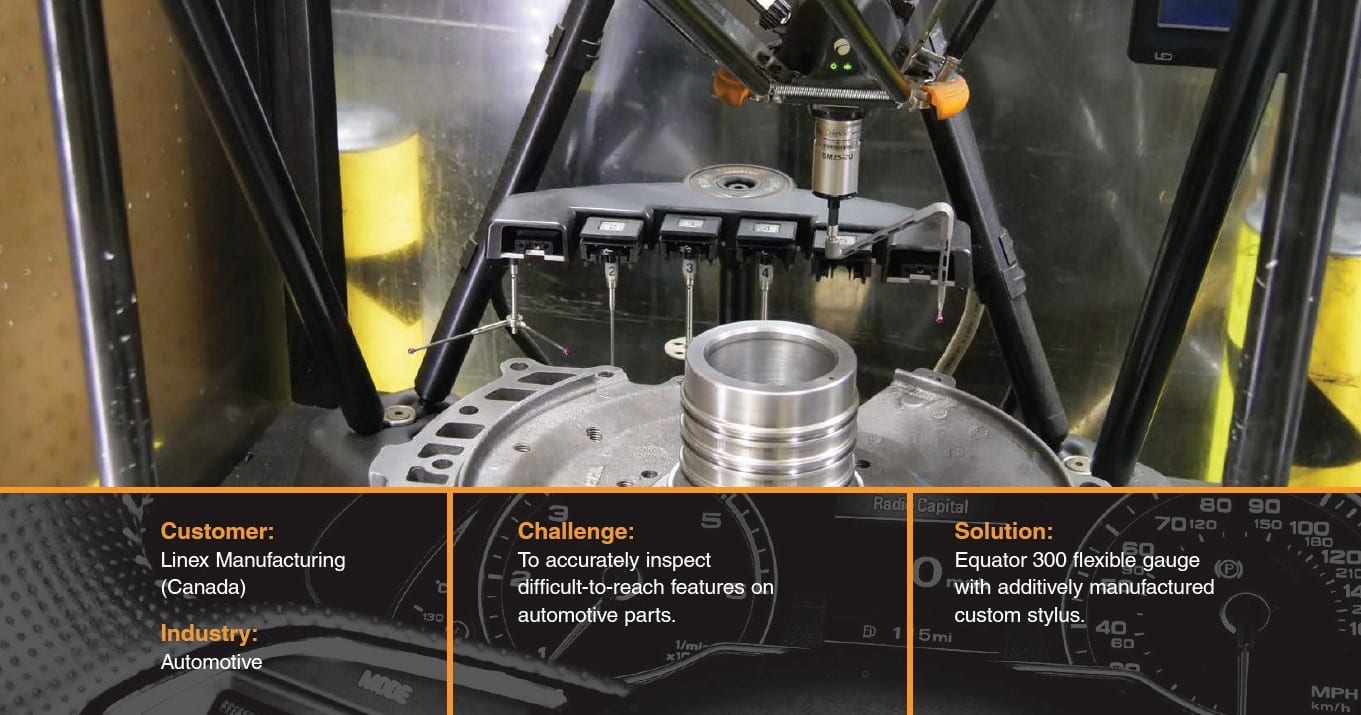

Overcome inspection challenges with our automated gauging systems, customizable styli, and additive solutions

A move to Renishaw's Equator™ 300 automated gauging system gave Linex Manufacturing all the inspection speed and accuracy it needed.

However, on a project implemented before the larger Equator™ 500 was available, bolt holes on the extremities of a workpiece lay just outside the gauge's working envelope. When standard styli and stylus extensions could not reach, Renishaw proposed the development of a custom stylus using metal additive manufacturing (AM), also known as metal 3D printing. The stylus was rapidly printed with a high-strength titanium alloy powder on a Renishaw RenAM 500Q metal additive manufacturing system using a process known as metal powder bed fusion, or laser melting.

The introduction of the custom-designed, additively manufactured stylus brought Linex the accuracy and repeatability it needed to inspect component bolt holes outside the Equator 300 gauge's working envelope. Narcis Georgescu (Senior Quality Supervisor at Linex Manufacturing) said, “Thanks to its robust, one-piece design, the titanium AM stylus has enabled us to carry out full component inspections. It brings a combination of lightness and stiffness that we could not achieve.” A few years on and the original AM stylus is still running without any degradation in its performance. Linex purchased a second AM stylus in the exact same design, and the company is now operating six Equator 300 gauges and one larger Equator 500 gauge.

Read the full case study here.

Visit Renishaw at IMTS 2022 this September (booth 135509-industrial metrology solutions and booth 433239-additive manufacturing systems) to learn more about our innovative products and find your perfect fit.

Utah Contract Manufacturer finds CMM solution from Masters Precision

Summit Peak Manufacturing Inc. (an ISO 9001:2015 certified company) was started by father and son Ken and Jordan Curry in the center of the Salt Lake valley. With extensive back grounds in manufacturing. The Father and Son found it a dream to start a machine shop, and started their adventure

Starting out with a Mazak C-600 and a Mazak QTU-250MY. Increase demands led to the purchase of Mazak VC-500C and Mazak C-600 with a 12-pallet Multi-Pallet system.

Key customers, Energy, Mining, Oil and Gas, Semiconductors, Medical, Aerospace, Defense

Summit wanted to insure there the quality of the services, based on years in manufacturing they knew that CMM’s is a necessity with complex parts and the need to perform quick measurements with customer requirements inspection data for parts. They needed a CMM that allows Summit Peak to load a part, let the part be inspected while engaged in other activities.

Creating a scope for their search include

- Inspection Envelope.

- Machine Construction

- Software – Open-source

- Cost

- Ease of use

- Customer Support

An extensive search involving multiple CMM sources, Summit Peak decided to purchase an Emerald 9158. From Masters Precision. This CMM has 900mm X travel, 1500mm Y travel, and 800mm Z travel. Exceeding the required measurement envelope, equipped with a Renishaw indexing heads, using Verisurf software, meeting their accuracy requirements the machine fit all of the needs they had outlined

With the Support of Master Precision, Summit Peak is confident that their Emerald CMM will be inspecting parts for many years to come.

810-223-6315

A universal metrology platform for all measuring devices

AEREM is a French company that designs and manufactures assembly and maintenance tools, as well as mechanical and fluidic test benches, for the aeronautics, aerospace, and pharmaceutical industries. MSL Métrologie is a partner who offers 3D measurement services on industrial sites in France and abroad, based on several years of experience with large aeronautics and aerospace companies. Both companies wanted a single metrology software to control their park of measuring devices.

In 2019, AEREM decided to retrofit their measuring instruments and review the software component. They consulted MSL Métrologie, a user of PolyWorks® Metrology Suite, and chose PolyWorks|Inspector™, a 3D dimensional analysis and quality control software solution. It can control their CMM, laser tracker, and measuring arm through plug-ins provided at no additional cost. “With this solution, we can quickly switch from CMM-based measuring to portable-arm based measuring,” says Vincent Renaud, Methods and Product Quality Control Officer at AEREM. He also appreciates the excellent training and technical support and uses PolyWorks|ReportLoop™ to send data to Excel and PolyWorks|Talisman™ to replicate the PC display on a mobile device.

MSL Métrologie uses PolyWorks to control their laser trackers, arms, and CMMs. They like the user-friendly, and intuitive interface, value its advanced features, and appreciate the follow-up and support provided by PolyWorks Europa, all of which help them offer customized solutions to their clients.

“For the InnovMetric group, service is an essential element,” says Thibault Hehlen, Commercial Manager of PolyWorks Europa. Together with its network of partners, InnovMetric has a technical support team with extensive experience in industrial metrology, product engineering, and manufacturing that includes over 150 application specialists directly supporting users in 43 countries.

“At MSL Métrologie, we believe PolyWorks is set to become the must-have software in the field of 3D metrology,” says Benoît Rotereau, company founder.

InnovMetric Software Inc

info@innovmetric.com

1‑888‑688‑2061

www.innovmetric.com

Taking Automotive Performance to the Next Level

with the Absolute Arm

With its headquarters and manufacturing facilities in Corona, California, advanced FLOW engineering (aFe Power) is a premier designer and manufacturer of automotive performance upgrade systems and components. With a product line of over 3,000 applications, aFe POWER designers and engineers turn to the state-of-the-art Absolute Arm to deliver the highest quality performance products in the industry.

“When we were using previous methods, I remember printing some parts three or four times before achieving the fit we wanted. With the Absolute Arm, we now print only one or two times before going to tooling. It was very important for me to get a good scanner that provides accurate data.” said Christian Landel, Design Engineer.

aFe POWER deploys two Absolute Arm 7-Axis systems, utilizing both the laser scanner and tube probe capabilities. Full engine compartment and underbody scans are made easy, thanks in part to the ultra-wide scan line on the laser scanner.

“It’s the best tool to scan the environment that we’re working with. Thanks to the durability of the Absolute Arm, we were able to place it right in the production area where we need it most. We prefer scanning the engine compartment rather than scanning a factory piece we’re going to replace because we want to start from scratch and not limit our creativity by starting with an existing part.”

The intuitive nature of the Absolute Arm allows aFe POWER to switch seamlessly between scanning, tactile, and tube probing, making it ideally suited for their needs.

Hexagon Manufacturing Intelligence

250 Circuit Drive

North Kingstown, Rhode Island, 02852

800.274.9433 | HexagonMI.com

Morgan Cars: Building on a Heritage of Classic Design

Recent evolution of Morgan cars has relied on technology advancements in metrology. Graham Chapman, Technology Manager, has deployed new measurement and inspection software to ‘digitise’ and preserve certain key characterises of Morgan chassis and body structures. “We needed a solution that was easy to use but provided high-end model-based functionality to meet our exacting engineering standards here at Morgan Cars. Morgan is a tradional methods car builder but that does not mean we reject new technologies to achieve our goals of a ‘British Classic,” said Graham.

Verisurf Software was selected as the measurement, inspection, and reverse engineering software of choice along with a portable CMM scanning arm. The software/hardware combination provides Morgan with a user-friendly digital route from hand-built components and assemblies to the CAD engineering team. The engineers can then produce up to date CAD designs of tradional legacy car platforms. This provides great insight into the current build process and gives a planning method for repeatability.

Model-Based Workflow Maintains Digital Continuity

Verisurf software is based on a CAD platform and supports Model-Based Definition (MBD) workflow, which is key to maintainng data integraty and relavance as part of the overall design and manufacturing process. When using MBD, the CAD model is the nominal to which all parts are measured and inspected against, keeping the all-important digital thread intact - from design to manufacturing to inspection and quality reporting. Everything that defines the part exists in a single digital archive, including how to manufacture and inspect the part. Based on its CAD platform and MBD functionality, the software is well suited for scan-to-CAD reverse engineering, inspection, tool building, and assembly guidance.

See Verisurf at IMTS booth #133345 for solutions in Quality Inspection, Reverse Engineering, and Tool Making.

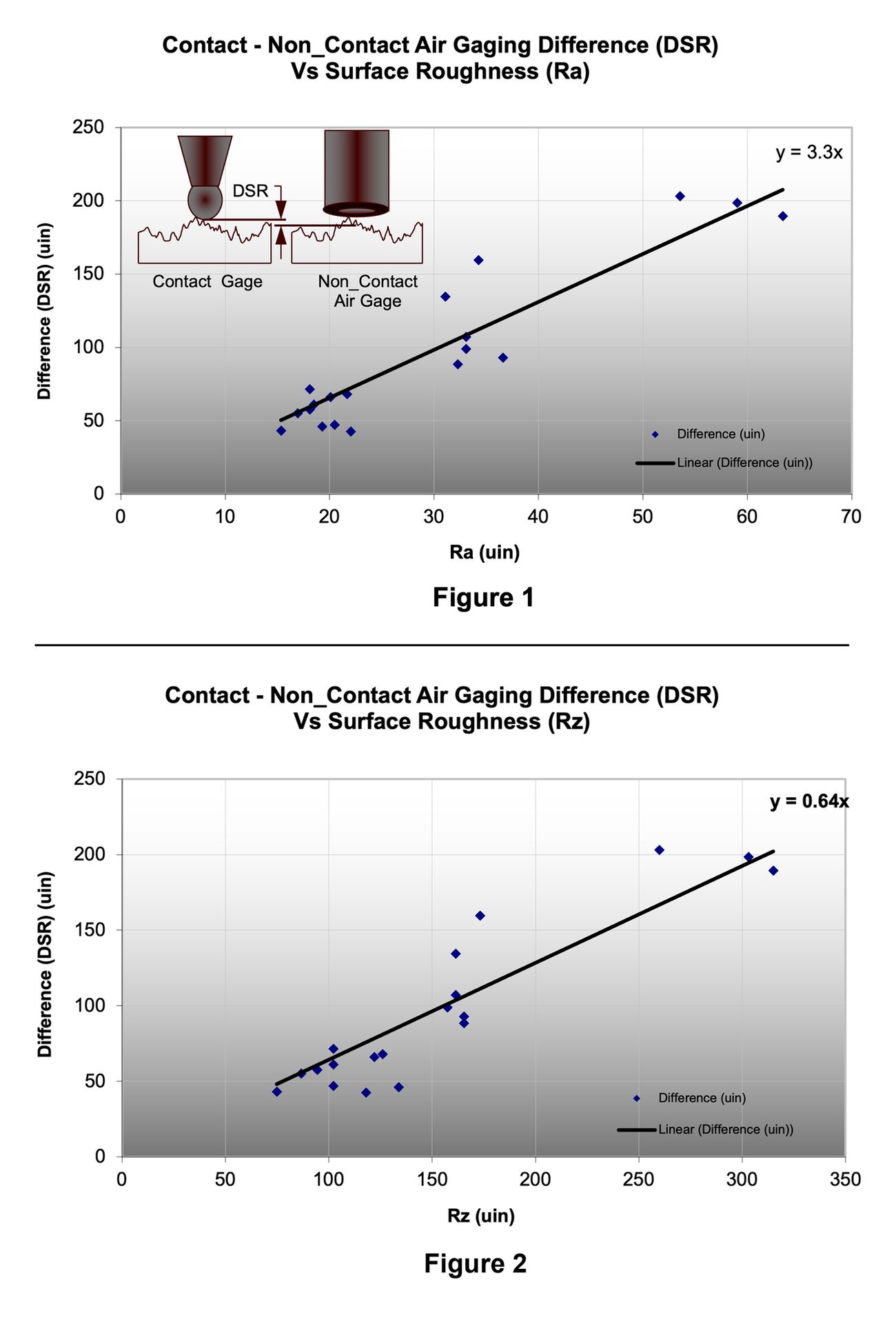

The Effect of Surface Roughness on Air Gaging Compared to Contact Gaging

When comparing contact gaging (stylus, probes) to non_contact methods (air gaging) the measurement difference due to the roughness of the workpiece surface must be taken into account. Where a perfectly smooth surface will show no difference in measurements, a rough surface will cause a reporting difference between the two methods. The stylus on a contact gage will tend to ride along the peaks of the surface and will therefore report the size based on the highest contact point, whereas in air gaging the air will disperse about the peaks and the valleys, resulting in a size that is approximately the centerline average of the high and low points of the surface. Thus air gaging will naturally report smaller for OD measurements and larger for ID measurements compared to contact gaging methods.

Below are the results of a study the quantifies the difference between a stylus gage (contact) and an air gage (non-contact) over a range of surface roughness. The surface roughness of 19 cylindrical OD parts 30.0065 mm (1.181358 inch) in nominal diameter were measured for surface roughness by Ra and Rz methods. These parts were also measure by contact gaging and air gaging methods. The air gage reported diameters smaller than the contact gage across the entire range of surface roughness, as expected for OD measurement. A graphical representation of gaging method difference vs Surface Roughness for both Ra and Rz are illustrated above in figures 1 and 2 respectively.