Compression Testing

Inspection

NDT

By Mark Fridman

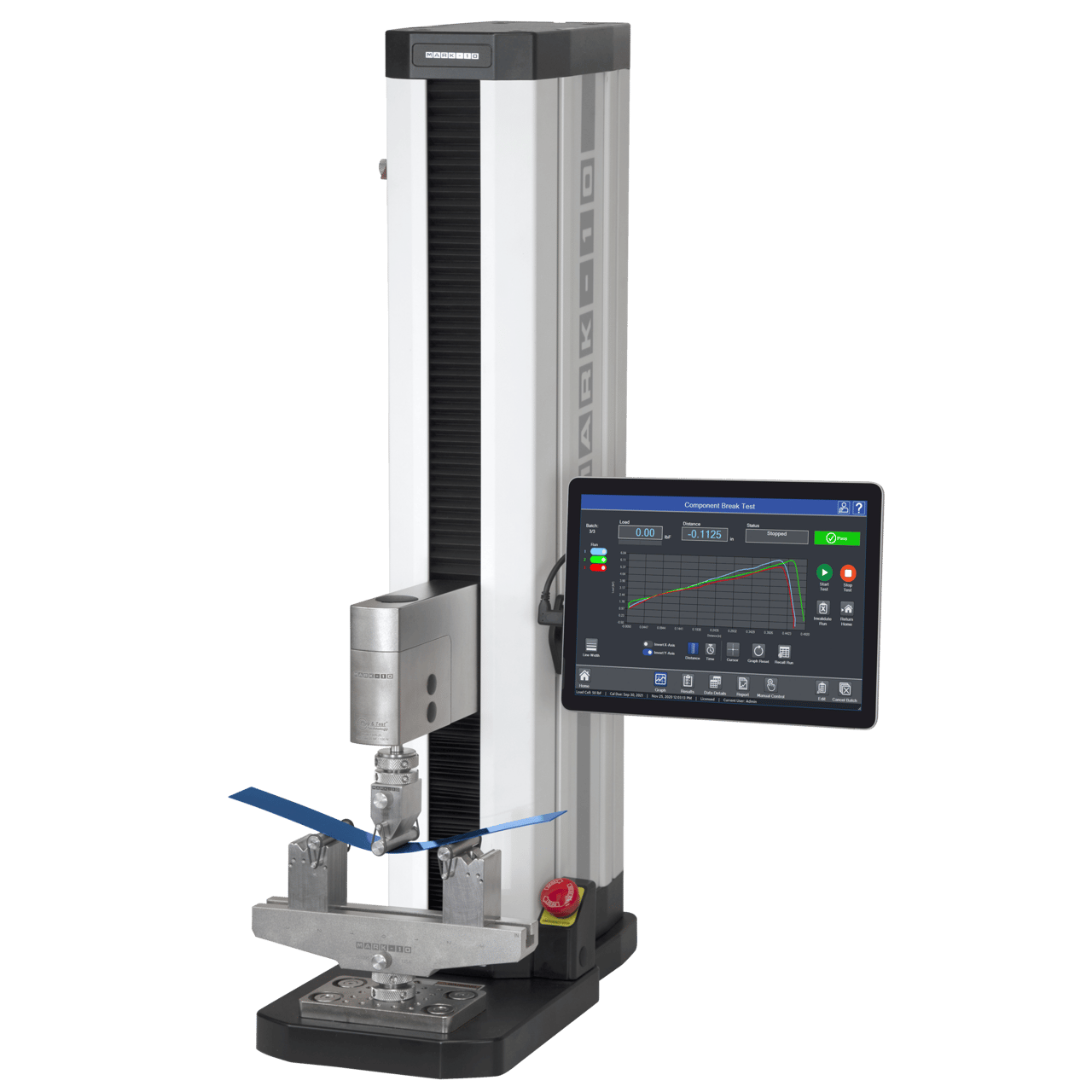

Squeezing the Most Out of Compression Testing

The data derived from compression testers can be helpful throughout the life cycle of a product.

Some of us enjoy watching videos on YouTube of random objects being crushed. Whether it’s an old shoe, a tube of toothpaste, or a cinder block, some enjoy a sense of satisfaction in seeing how something unravels when subjected to crushing compression forces. For manufacturers around the world, breaking stuff can be entertaining, but it’s serious business when it comes to determining the quality of their products.

Under controlled conditions and with appropriate test equipment, compression testing provides quality engineers, inspectors, and research professionals with data they need to determine a material or component’s physical characteristics for quality assurance, design suitability, and customer satisfaction.

When Is Compression Testing Needed?

Besides some of the fun examples above, there are millions of more mundane, and often unseen, applications for compression testing. Here are some examples:

Compression Spring Testing: Springs are essential components in everything from pens to mattress to automobiles. To ensure optimal performance, a compression force is applied to determine corresponding force. Several parameters are often measured, including spring rate, spring force, force at a given deflection, and deflection at a given force. Understanding the mechanical performance of a spring is critical in specifying which spring to use in a product design.

Top Load Testing: Top load testing is popular for packaging, beverage, and consumer products manufacturers. Bottles, containers, cans, and cartons are required to resist compression loads that could damage them. In top load testing, a compression force is applied until it deforms by a specified amount or collapses. An example of such testing is measuring the top load on a common water cooler bottle. Such measurements must meet minimum standards to prevent damage to the bottle or its contents during transportation or customer handling. The results of a top load test can identify failures in the molding process or in the formulation of the material.

Bend Testing: Bend testing subjects plastics, wood, carbon fiber, and other materials to compression forces at three or four points. The resulting deflection and compression forces are measured, and used to quantify strength, elasticity, and other characteristics. This information helps materials producers meet specifications and assist other manufacturers in specifying materials in their designs.

A compression force tester can determine bending characteristics via a 3- or 4-point bend test.

How to Perform a Compression Test

Compression testing may be done by benchtop force measurement systems. Most systems are universal, capable of both tension and compression testing, and consist of a few main components:

Test frame

Force sensor

Machine control and data collection software

Grips and fixtures

The first step in configuring a compression tester is identifying the test objective. Then, determine the expected maximum force, maximum sample dimensions, and maximum sample deformation or extension. This information will aid in selecting the required components of a complete system:

Test frame: Test frames, whether motorized or manual, produce the force necessary for the test. With motorized frames, the speed may be preset to ensure that tests are performed consistently.

Compression spring testing yields important data for spring manufacturers and the design engineers who specify their use in a product.

Select a test frame capacity appropriate to the expected maximum force. Single-column electromechanical test frames are normally offered in many increments, such as 100 lbF (500 N), 300 lbF (1.5 kN), 500 lbF (2.2 kN), 750 lbF (3.4 k), and 1,500 lbF (6.7 kN). Higher capacities are often configured as double-column systems and may be hydraulically driven. Dual-column test frames also offer the advantage of unlimited depth clearance, ideal for oddly shaped or oversized samples.

Force sensor: A force sensor, or load cell, measures tension and compression forces, and is available in many force capacities. Choosing the correct capacity optimizes accuracy and measurement resolution. Ideally, a force sensor should be used at no less than 5-10% of its range. For example, a compression spring requiring 36 lbF is best served by a 50 lbF force sensor with 0.02 lbF resolution. Using a 1,000 lbF sensor with 0.5 lbF resolution would result in lower accuracy as a percentage of the reading.

Grips and fixtures: Catalogs full of generalized and application-specific grips are offered by compression tester manufacturers and grip specialists. For example, 3- / 4-point bend fixtures allow the user to position anvils at specific positions to achieve the desired bend. Compression plates of various sizes engage springs, bottles, and other objects. In some cases, users source their own custom solutions, which could be 3D printed, machined, or fabricated via other means.

A multi-step test editor allows the user to customize a series of motion control and data collection steps particular to the application.

A variety of results are calculated in compression testing software, such as maximum load, load at maximum distance, delta distance, height, and others.

Squeezing the Most Out of Software

Recent advancements in force measurement software provide powerful tools for creating test procedures and analyzing data, while simultaneously being more integrated with the test frame and force sensor.

Using some of the above application examples, newer advanced software allows users to create custom test executions without any programming knowledge. Here are two examples:

Compression Spring Test to Multiple Heights: Springs may be compressed to a height to determine the resulting force and spring rate. For example, a test procedure might call for measuring the free (original) height, followed by one or more heights, as follows:

Prompt the operator to enter a lot number

Touch the top of the spring – pre-load of 0.2 lbF

Measure the free height

Compress to 4 in. height

Record the force

Compress to 3 in. height

Record the force

Return to home position

Fatigue Test of Plastic Material

Plastics are employed liberally in products we take for granted, with newer formulations taking the place of more traditional materials like wood and metal. To determine suitability of a material for a given application, a complex test procedure can be helpful, such as the following:

Prompt the operator with instructions and an image of the testing setup

Touch the top of the material – pre-load of 0.2 lbF

Zero the travel display

Compress by 0.5 in.

Record the force

Return to home position

Compress by 1 in.

Record the force

Return to home position

Repeat steps 2 through 9, 50 times

The results generated by these tests are displayed in tabular format directly within the machine control software. Selected results and operator prompt responses correspond to run numbers (for example, 10 runs in a batch). Statistics may be applied to the results of multiple runs to determine trends. Results can be output to a .csv file or used to generate a report for further analysis and record keeping. Previous runs can also be viewed on the graph simultaneously, to more easily compare the behavior of multiple samples.

To avoid buckling or rupture in the field, plastic water bottles are subjected to a top load compression test.

Summary

Compression testing gives manufacturers confidence that their products meet specifications, customer expectations, and are safe. The data derived from compression testers can be helpful throughout the life cycle of a product, from the design process to prototype analysis, to ongoing production inspection. Effective compression testing can not only ensure compliance with standards and regulations, but can buoy a company’s reputation in the eyes of their stakeholders. And sometimes, it’s even fun to watch.

All Images Source: Mark-10 Corp. Video source Getty Images

Ian R. Lazarus is president and CEO of Creato Performance Solutions, providing leadership development, training, and solutions to support operational excellence.

Mark Fridman is the president of Mark-10 Corp. For more information, call (888) MARK-TEN, e-mail mf@mark-10.com or visit www.mark-10.com.

Jim L. Smith has more than 45 years of industry experience in operations, engineering, research & development and quality management.