America Makes continues to fulfill its mission of building an additive manufacturing (AM) talent pipeline across the state of Ohio with the announcement of the Ohio Secondary Education Additive Manufacturing Training Network.

Created in collaboration with and support from the Ohio Development Services Agency (OSDA), this network will provide formal education and training of AM technologies to high school students and their educators to ensure the next generation of Ohio workers are equipped with the skills to fill advanced manufacturing jobs. Initially, 10 high schools statewide, including those in both urban and rural settings and representing public, charter, and career and technical schools are participating in the network. This America Makes Education and Workforce Development (EWD) program is funded through the Fiscal Year 2020-21 State of Ohio operations budget.

According to the 2020 Ohio Manufacturing Report by the Ohio Manufacturing Extension Partnership (MEP) & MAGNET, 57% of Ohio’s manufacturers indicated that the skilled worker shortage is the number one challenge impeding business growth. The Ohio Manufacturing Report aligns with national findings released by a 2021 study from Deloitte and The Manufacturing Institute, which projects that by 2030 more than 2.1M U.S. manufacturing jobs are likely to go unfilled. The reason? The manufacturing skills gap. Eighty-two percent of those national respondents also reported that revenue growth is stagnating because of the inability to find skilled talent.

However, programs like the America Makes’ Ohio Secondary Education Additive Manufacturing Training Network are exactly the types of initiatives that can help to reverse this trend according to the Deloitte and The Manufacturing Institute study. The network significantly expands training opportunities for both Ohio students and educators.

“There’s no question that our state and our nation are facing a significant skilled labor shortage and misalignment of skills and competencies,” said Josh Cramer, America Makes Education & Workforce Development Director. “We need to take action now with K-12 students, with immediate emphasis on focusing on secondary education students and empowering their educators—from teachers to principals and guidance counselors—to help them increase students’ awareness of AM technologies and advanced manufacturing careers. The awareness vacuum around manufacturing career opportunities is an even larger issue than the skills gap. With the creation of the Ohio Secondary Education Additive Manufacturing Training Network, we are building that critically needed additive talent pipeline across the state of Ohio.”

The Ohio Secondary Education Additive Manufacturing Training Network leverages best practices and industry-vetted content/curriculum from America Makes and its membership community; offers industry recognized credentialing and badges; and provides tailored training and coaching to teachers, principals, and counselors. It also includes a middle school toolkit, complete with teacher training, to encourage interest in AM in these students. Each school in the network is also receiving AM technology packages of six Dremel DigiLab 3D45 Advanced Idea Builder 3D Printer bundles with materials and supplies. Additionally, each school will receive support for community engagement activities, open houses, and participation in national AM events like RAPID + TCT 2021.

The 10 Ohio secondary schools participating in the network are:

Grant Career Center

Horizon Science Academy Columbus High School

Apollo Career Center

Ashtabula County Technical and Career Center (A-Tech)

Butler Tech

MCCTC and Valley Stem

The Dayton Regional STEM School

Windham Exempted Village Schools

Theodore Roosevelt High School

Marietta High School

For more information, visit www.americamakes.us.

America Makes Announces the Ohio Secondary Education Additive Manufacturing Training Network to Address State’s Skilled Worker Shortage

East Coast Metrology, LLC announced its immediate expansion into Canada through a partnership with Precitech Metrology, a full-service 3D metrology and precision alignment company based in Montreal, Quebec.

In collaboration with Precitech Metrology, ECM is now able to offer customers in Canada an ISO/IEC 17025 Accredited Calibration Certification for all portable new or pre-owned measuring instruments including laser trackers, laser scanners and portable CMM arms. With the local benefits of Precitech and the long history and experience of the two companies working together in Canada, customers will have a convenient solution while eliminating the challenges often seen when parts and equipment cross the border. “Over the years we have developed a strong working relationship with Precitech Metrology, and we are excited to advance this to the next level. Precitech will be instrumental in our continued expansion of service offerings throughout North America,” Gary Confalone CEO - ECM Global.”

Furthermore, ECM announces the launch of their dedicated Canadian website focused on portable measuring equipment calibrations. Please visit https://EastCoastMetrology.ca to learn more.

“We are very proud to announce this collaboration with ECM. Together we have effectively eliminated a large source of lost time and resources for our current and future Canadian customers. We are excited to be offering our customers certified laser tracker, laser scanner and portable arm calibrations in Canada. We also look forward to future collaborations aimed at improving our customers’ efficiencies,” Paolo Miele, president - Precitech Metrology.

For more information, visit www.Eastcoastmetrology.ca.

ECM Announces Expansion Into Canada

AMT – The Association For Manufacturing Technology, and NCATC, the National Coalition of Advanced Technology Centers, announced that Greg Jones, vice president, Smartforce Development, AMT, was elected to the NCATC board of directors to occupy one of two Strategic Partner seats on the board for a term of two years beginning July 1, 2021.

“I am honored to join the NCATC board of directors,” said Jones. “AMT has been a Strategic Partner of NCATC for about a decade, and I have worked closely with Craig McAtee, CEO and executive director at NCATC, and its members as part of AMT’s strategy in solving the skills gap that exists in U.S. manufacturing. NCATC member schools and all of the NCATC Strategic Partners are pivotal to advancing technology in school programs as well as diversity and inclusion in career and technical education.”

As a leader in the manufacturing technology community, AMT focuses on supporting manufacturers with vital information on technological developments, especially in emerging, transformational technologies, advocating for a next-generation Smartforce, and building dynamic, data-based ecosystems that nurture new manufacturing process innovations. By addressing these areas, AMT maximizes the development of our members as they adapt to new paradigms and business models and contributes to the overall growth of the manufacturing technology industry.

At AMT, Jones leads Smartforce Development, AMT’s effort to build a better-educated and trained workforce for the advanced manufacturing industry. To accomplish this, he forges relationships with industry, education, and governmental organizations to develop and promote workforce programs. Jones is also a member of the executive committee of the board of directors of the National Institute for Metalworking Skills (NIMS) and a board member of The American Precision Museum in Windsor, Vermont. In 2001, Jones was also part of the executive team that launched ToolingU, the manufacturing industry’s leading e-learning platform, which is now owned by SME. Jones volunteers as a judge for the national SkillsUSA Championships for CNC machining, where AMT is a Manufacturing Career Cluster sponsor.

“Greg Jones has it all – subject matter expertise, true collaboration mentality, ego checked at the door, and genuine passion for lifelong learning (K to Gray) – especially in the advanced technology and manufacturing space. I personally have had the honor and pleasure of working with Greg on many CTE and workforce development initiatives over the past two decades, from his start-up leadership at ToolingU in Cleveland to his present role as vice president of Smartforce Development at AMT – The Association for Manufacturing Technology as a key Strategic Partner with our organization since 2010. We are ecstatic that Greg has been elected to serve a two-year term on the NCATC board of directors beginning on July 01, 2021,” said Craig McAtee, CEO and executive director, NCATC.

For more information, visit www.amtonline.com.

AMT Exec Appointed to NCATC Board of Directors

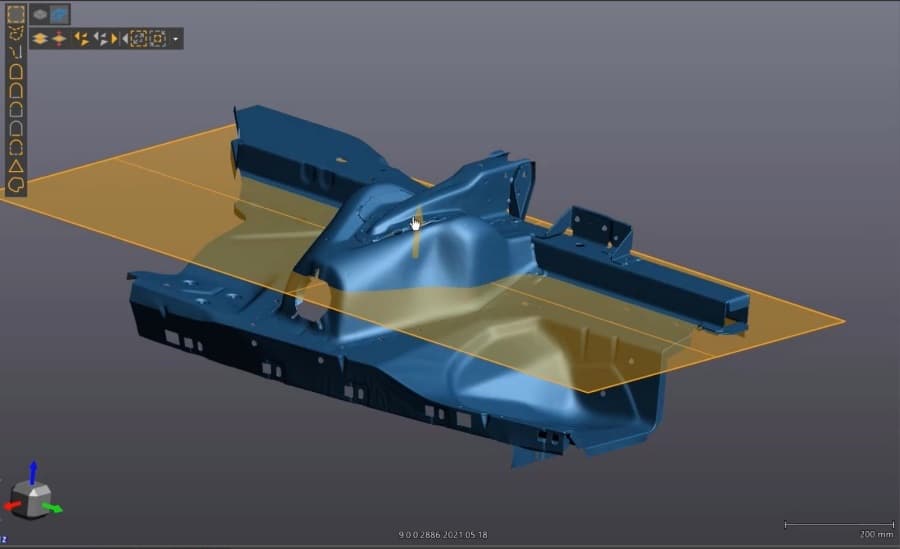

Creaform announced that it became an official partner of BBi Autosport for the 2021 Pikes Peak International Hill Climb (PPIHC) that will take place on June 27, 2021, in Colorado, USA. BBi, specialized in performance aftermarket and safety upgrades for all Porsche platforms as well as engineering services, decided to leverage the power of Creaform’s hardware and software 3D solutions, which proved to be instrumental in meeting the short deadlines that the team was facing, prior to the race.

Known as the “Race to the Clouds” and one of the most reputed and arduous car racing events in the world, PPIHC is one of the hardest events to prepare for, given the unpredictable and brutal nature of the environment. As BBi needed to work quickly on their impressive and updated aerodynamics within three racing classes, they were looking for a way to rapidly and efficiently acquire 3D measurements to collect accurate data about the performance and reliability of many diverse race-car components. They also wanted to reduce their reliance on third-party service providers by getting a fast and versatile solution to generate scan data immediately workable to create new parts.

BBi Autosport decided to gain 3D scanning independence by acquiring Creaform’s Go!SCAN SPARK, the fastest metrology-grade 3D scanner that can be used throughout an entire PLM workflow. Matched with Creaform’s VXelements 3D software platform and application suite, it quickly measured all types of complex geometries and surfaces—all while getting the highly accurate measurements right the first time around. Able to scan wherever and whenever they wanted, the R&D team saved valuable development time and were able to roll out the necessary parts as fast as they needed them.

According to Dmitriy Orlov, COO at BBi Autosport, “Creaform has created a powerful package that not only gathers highly accurate data with unprecedented freedom and ease but also offers a robust software package that handles and processes that data for easy integration into almost any CAD design workflow.” He continued by adding that, “3D scanning is a crucial element to help us in design and validation. In general, 3D scanning means we can do more in virtual, saving time on cutting things up, saving on mistakes and accelerating the creation of needed parts.”

For more information, visit www.creaform3d.com.

BBi Autosport Partners with Creaform for 99th Pikes Peak International Hill Climb

The U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) announced a new competition for awards to support industry-driven consortia in developing technology roadmaps that will address high-priority research challenges to grow the advanced manufacturing sector in the U.S.

NIST’s Manufacturing USA Technology Roadmaps (MfgTech) program anticipates awarding up to eight awards with a period of performance of up to 18 months each, with individual awards of up to $300,000 and no cost-share requirement. The competition is open to all nonfederal U.S. entities, including accredited institutions of higher education; nonprofit organizations; for-profit organizations incorporated in the U.S. (including U.S. territories); and state, local, territorial and tribal governments.

Technology roadmaps are proven, strategic tools to identify barriers and related development steps to achieve grand challenges. Prior roadmap activities have been instrumental in establishing productive consortia and initiatives, including foundational planning for future Manufacturing USA institutes. Benefits of technology roadmaps include:

Addressing major technological barriers that inhibit the growth of advanced manufacturing in the U.S. that no single organization could tackle on its own;

Identifying and prioritizing research projects supporting long-term industrial research needs including but not limited to those identified in the Strategy for American Leadership in Advanced Manufacturing;

Creating new or updating broadly available industry-driven, shared-vision technology roadmaps to support strategic and long-range planning; and

Catalyzing development and supporting the maintenance of a technology infrastructure and American excellence in advanced manufacturing, including identifying technology areas appropriate for potential new Manufacturing USA institutes.

“The Manufacturing USA institutes have demonstrated that consortia can play a key role in developing and transitioning new manufacturing technologies critical to America’s future competitiveness,” said Mike Molnar, director of NIST’s Office of Advanced Manufacturing. “These roadmaps can help ensure that we have a clear vision of what challenges are before us to ensure U.S. manufacturing is competitive.”

Organizations that submit MfgTech proposals are encouraged to develop partnerships across an industry ecosystem to bring together expertise in facilities, supply chain, or specialized goods and services to produce a valuable roadmap that takes all of these elements into consideration.

Proposals are due by Aug. 16, 2021. Details about the competition, including eligibility, selection criteria, legal requirements and the mechanism for submitting proposals are found in the Notice of Federal Funding Opportunity posted at Grants.gov under funding opportunity number 2021-NIST-MfgTech-01.

NIST will host a webinar on June 25 at 2 p.m. EST to share more information on the program and preparing proposals. For more about webinar details, including how to register, visit https://www.nist.gov/oam/manufacturing-usa-technology-roadmap-mfgtech-program.

The Manufacturing USA institutes and their sponsors — the U.S. Departments of Commerce, Defense or Energy — connect more than 2,000 organizations across hundreds of major projects to quickly move technology from laboratory prototypes to industrial capabilities and provide thousands of people with advanced manufacturing knowledge and skills. For more information, visit www.ManufacturingUSA.com or www.NIST.gov.

NIST Launches New Manufacturing USA Technology Roadmap Grant Competition

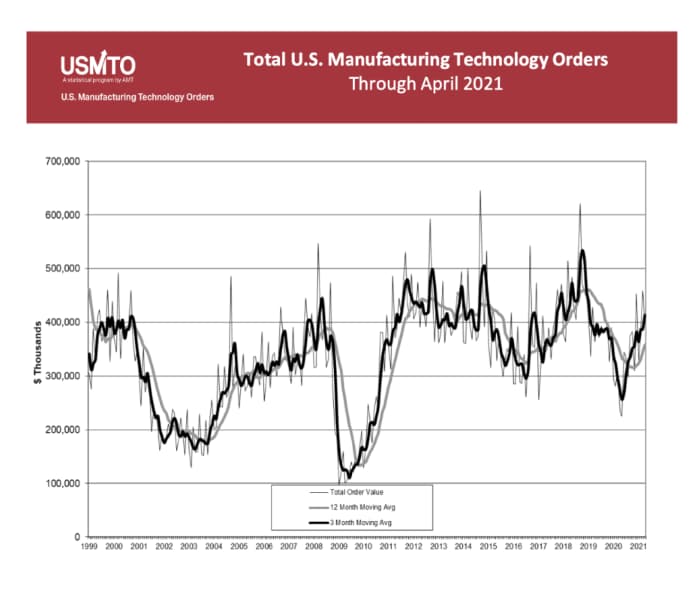

U.S. Manufacturing Technology Orders totaled $404.6 million in April 2021, a decline of 12% from March 2021 but an increase of 72% from April 2020, according to the latest U.S. Manufacturing Technology Orders report published by AMT – The Association For Manufacturing Technology. Total orders for 2021 reached $1.57 billion YTD, an increase of 40% over orders placed in the first four months of 2020.

“April 2020 had the lowest orders in a decade, but the previous three months were business as usual, so to be 40% up over the previous year shows the real strength of the industry in 2021,” said Douglas K. Woods, president of AMT. “Parts that would normally go to job shops are now being produced in-house by larger manufacturers with the means to increase their production capacity. This is not to say production is shifting away from job shops; they are still operating at near capacity and increasing machine orders month over month, but increased consumer demand has necessitated more capacity, and confidence in the sustainability of that demand has justified the capital expenditure by large OEMs. As a result, our members have seen a resurgence of multi-machine orders near 2018 levels.

“There has been strong demand for metal cutting technologies in 2021, and orders for new forming technologies have more than doubled where they were at this point in 2020. Cosmetic automobile design changes drove increases in forming technologies and helped spur demand for cutting technologies from the mold and die industry. April orders were further strengthened by energy exploration and mining expanding out of Texas into nearby regions in response to increased market prices. Industries related to consumer products also increased orders in April, such as off-road vehicle manufacturing, electrical equipment manufacturing, and commercial and service industry machinery.

“Another optimistic sign for the industry is the number of open houses our members report having over the past few weeks where attendance has exceeded their expectations. This signals a renewed comfort with in-person sales calls and a pickup in regular maintenance as opposed to emergency visits. However, supply constraints have meant new orders are being added to an already growing backlog. The demand for manufacturing technology is there, and the suppliers who can deliver on orders will be in a position to one-up their competition in the near term.”

For more information, visit www.amtonline.org.

US Manufacturing Technology Orders Up 72% Year-Over-Year

The U.S. Department of Energy (DOE) announced the latest cohorts in its Lab-Embedded Entrepreneurship Program (LEEP). The 22 selected innovators will join an extensive network of mentors and experts at U.S. national laboratories to develop the next-generation technologies that will help pave the way to a clean-energy future.

The program is a two-year fellowship that places some of the nation’s brightest scientists and engineers with national laboratories. During the fellowship, they will perform critical research and development that will ultimately bring their technologies from lab to market. The program also helps these innovators develop their entrepreneurial acumen, preparing them to launch successful energy and manufacturing businesses.

“The Lab-Embedded Entrepreneurship Program helps promising scientists and engineers overcome what can often be their most difficult challenge in clean-energy innovation: moving their technologies out of the lab and into the marketplace,” said Acting Assistant Secretary for Energy Efficiency and Renewable Energy Kelly Speakes-Backman. “We are eager to support these entrepreneurs through this mentorship program, which will help to bring new technologies to market, and accelerate the decarbonization of our economy, and launch new careers in clean energy.”

This year’s selected innovators will focus on developing technologies to increase energy and material efficiency in U.S. manufacturing, which in turn will help decarbonize the industrial sector. The cohorts will participate in the following DOE programs:

Chain Reaction Innovations at Argonne National Laboratory in Lemont, Illinois: The Chain Reaction Innovations program’s latest cohort includes five innovators working on technologies in decarbonization, water treatment, lightweight composites, and additive manufacturing.

Cyclotron Road at Lawrence Berkeley National Laboratory in Berkeley, California: The Cyclotron Road program’s cohort will include 11 innovators working on technologies in additive manufacturing, energy storage, and plastics.

Innovation Crossroads at Oak Ridge National Laboratory in Oak Ridge, Tennessee: The Innovation Crossroads program’s cohort will include six innovators working on hydrogen storage, batteries, water treatment, building material, cybersecurity, and additive manufacturing.

The LEEP is primarily funded by EERE’s Advanced Manufacturing Office (AMO). The Building Technologies Office within DOE, along with Defense Advanced Research Projects Agency, Tennessee Valley Authority, and several philanthropic organizations will also fund innovators this year.

Since the program’s inception in 2015, AMO has awarded more than $40 million to innovators running 79 start-ups. As of May 2021, program participants have gone on to attract nearly $320 million in additional federal funding and follow-on private funding from philanthropy, angel investors, venture capital, and strategic investors.

For more information, visit https://www.energy.gov/eere/amo/lab-embedded-entrepreneurship-program.

Twenty-Two Innovators Selected for DoE’s Lab-Embedded Entrepreneurship Program

Scroll Down

Scroll Down