Products

Showcase/Best in Show

Showcase/Best in Show

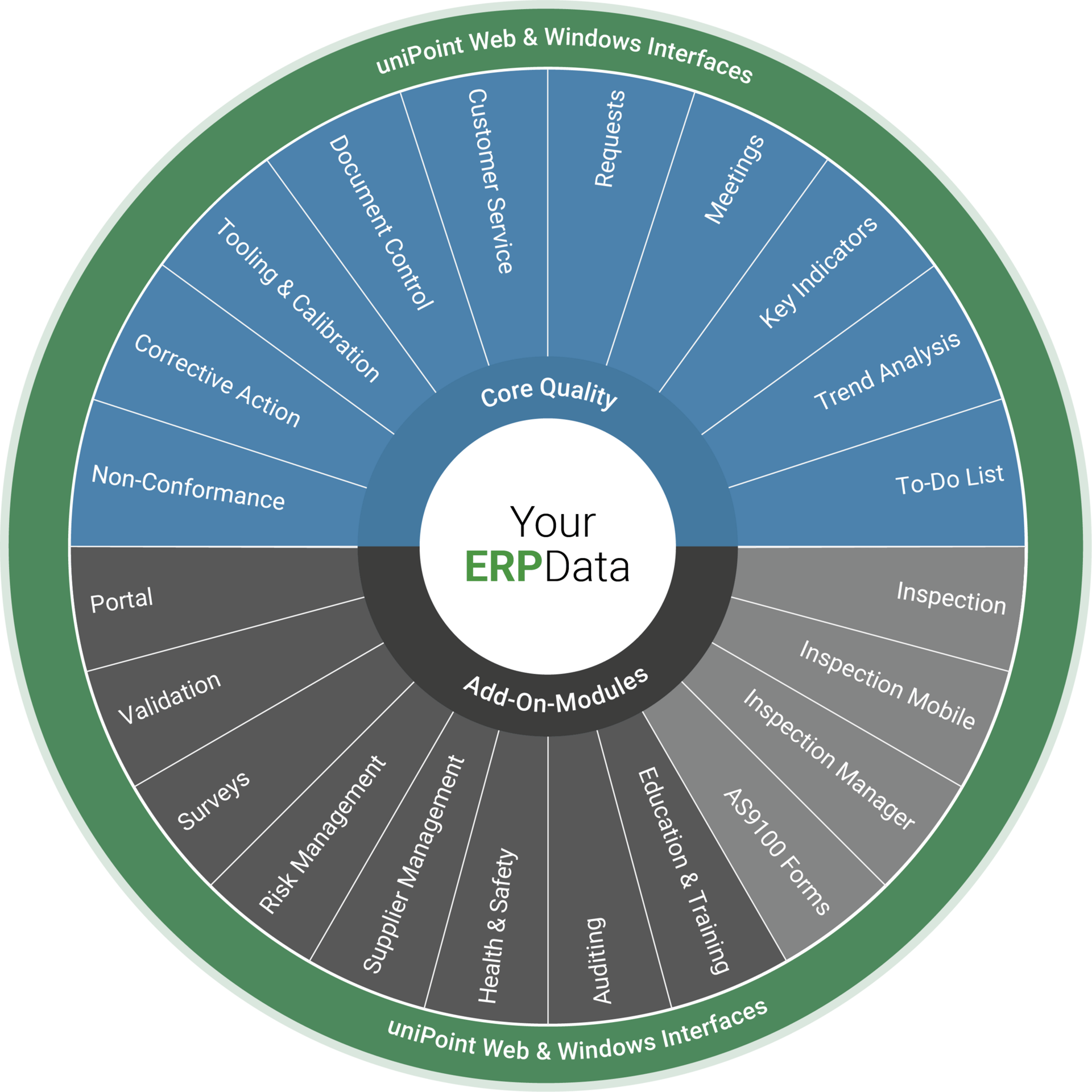

uniPoint Software

uniPoint Software is an Enterprise Quality Management System (EQMS) offering a complete ISO compliance solution for small, medium and large-enterprise manufacturing companies across a broad spectrum of quality-conscious industries. Our 23-module system integrates with over 50 ERP systems and is simple to install, use and implement. Our inspection module includes Bubble Drawing capability with optical character recognition, complete wireless mobility and the option to eliminate all data entry by transferring data automatically from your CMM machine into our inspection records. Never fail an ISO audit again and give your employees the ability to inspect the quality of their own work from the plant floor!

uniPoint Software Inc.

BOOTH 363

www.unipointsoftware.com

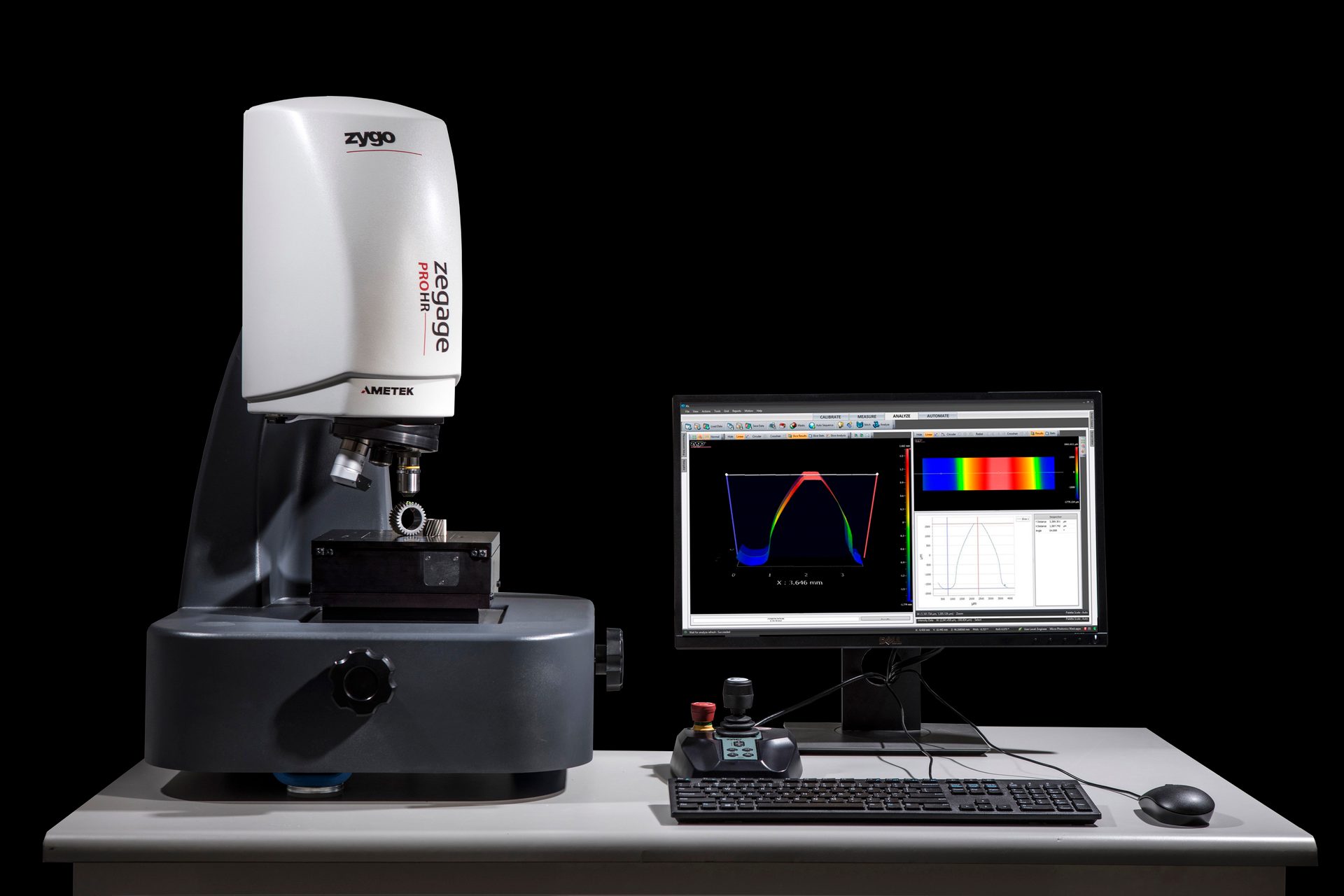

Zygo ZeGage 3D Optical Profiler

Zygo will highlight its 3D Optical Profilers, including the ZeGage Pro. The ZeGage Pro uses Coherence Scanning Interferometry (CSI) for precise, non-contact surface measurements. This well-established method ensures exceptional accuracy in measuring height variations, such as surface roughness.

The system features a compact, benchtop-friendly design and incorporates SureScan™ technology, eliminating the need for expensive vibration isolation tables and system enclosures. It operates with Zygo's Mx™ software, which offers comprehensive tools for surface data visualization, analysis, and reporting. Mx™ provides interactive 3D maps, quantitative topography data, intuitive navigation, and built-in SPC with statistics, control charting, and pass/fail limits.

The ZeGage Pro brings nanometer-scale surface mapping to production environments, offering superior gage capability. Its proprietary non-contact measurement technology, enhanced with SureScan™ technology, ensures low sensitivity to vibration and easy placement within a production facility. The system also includes Zygo's exclusive Part Finder and Smart Setup tools, facilitating fast and easy sample changes to maximize throughput.

Zygo provides tailored optical solutions across industries such as Semiconductor, Life Sciences, Machine Vision, Aerospace and Defense, and Medical Devices. Their strength lies in their consultative approach, advanced engineering, and precision manufacturing. As part of AMETEK’s Ultra Precision Technologies Division, Zygo offers world-class expertise to solve the most complex challenges, setting new standards for quality and innovation in the global market.

Zygo

BOOTH 522

www.zygo.com

Faro Technologies Faro Leap ST Handheld Scanner

Faro® Technologies, Inc., has entered a new category of handheld scanning with the launch of Faro Leap ST®. The new handheld solution expands the company’s product portfolio, making Faro one of the few companies offering customers a complete range of portable 3D metrology devices. It strengthens Faro’s presence across the manufacturing sector, where speed, accuracy, and throughput are key. Faro paired this launch with an update to its Faro CAM2® Software, for a simple and effective way to scan parts.

Leap ST features five powerful operating modes: ultra-fast scanning, hyperfine scanning, deep hole scanning, large area scanning, and photogrammetry. As a metrology-grade tool, it excels in measuring and verifying a variety of surfaces and parts. The design is compact, portable, and suitable for multiple industries and applications.

Additionally, Faro enhanced its 3D metrology software offerings with the update of CAM2. The software now includes five tailored versions that address specific manufacturing measurement requirements. CAM2 now offers options for scanning devices and probing devices, as well as a hybrid approach that integrates probing and scanning for solutions such as the FaroArm with laser line probes.

Faro Technologies, Inc.

BOOTH 537

www.faro.com

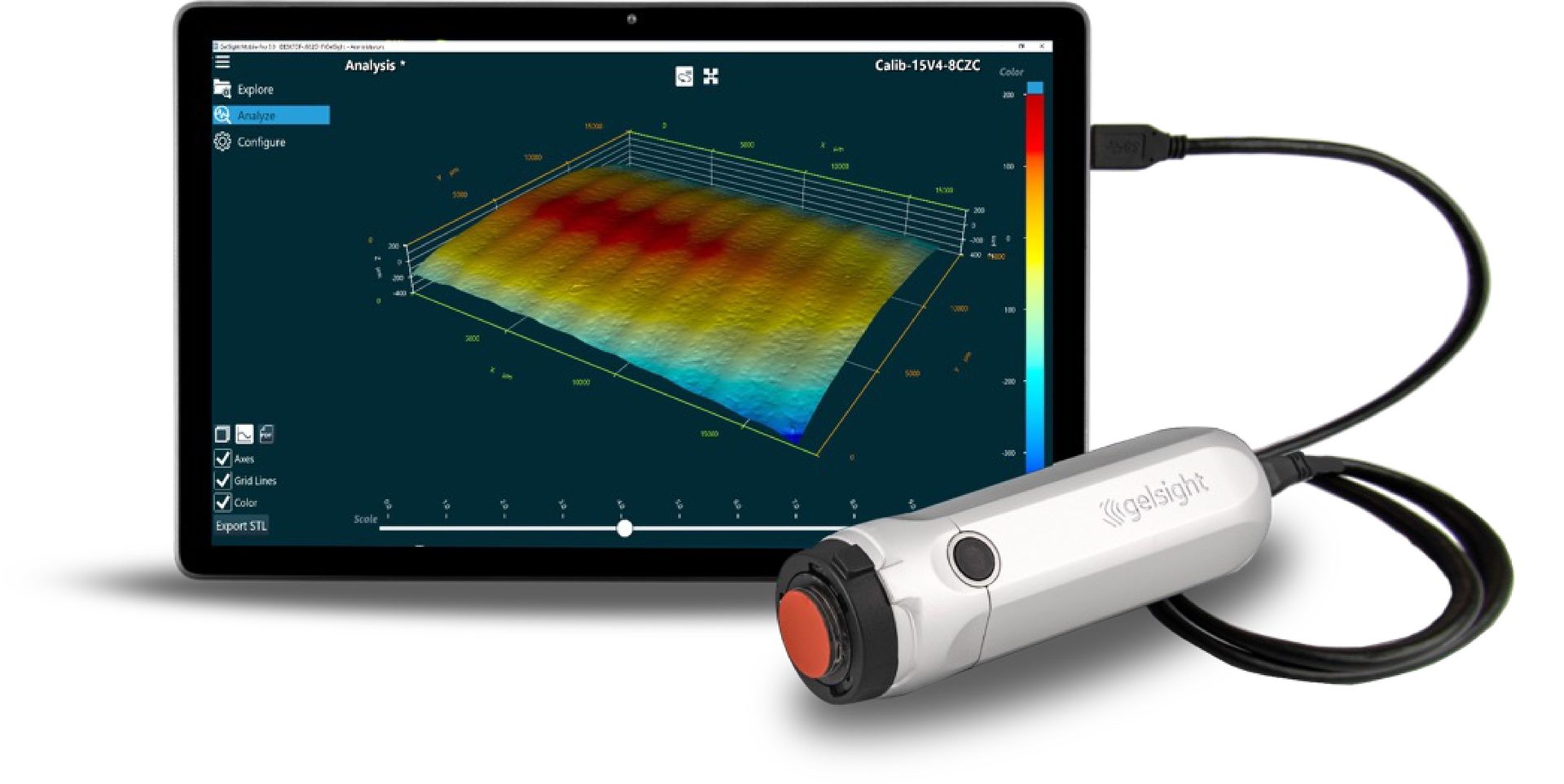

GelSight Mobile 4.0 Software

GelSight Mobile™ is a handheld instrument that precisely visualizes and measures the 3D topography of any surface, revealing microscopic structures that are difficult to detect using traditional inspection techniques. GelSight’s proprietary elastomeric tactile sensor technology enables GelSight Mobile™ to be used on Any Material, Anywhere™—including metal, glass, carbon fiber, or textiles.

In the 4.0 update, GelSight customers’ top requested capabilities for GelSight Mobile are now live. Customers can now easily combine scans to inspect larger surface areas with automated image stitching. GelSight has also taken our existing 2D measurement tools and expanded them to create a dedicated 2D measurement analysis function. These tools enable simplified workflows and deliver significant improvements for routine measurements, inspection cycles, and more.

Some of the key features in the GelSight Mobile™ 4.0 Software include:

- Image Stitching: Combine multiple scans with our simple guided workflow to create larger areas to apply GelSight’s 2D and 3D surface analysis tools with the same accuracy, speed, and ease of use you have come to expect from GelSight. One image is automatically stitched from multiple to enable the analysis of larger surfaces and features, such as scratches spanning multiple centimeters. During early field testing, GelSight was able to detect a scratch an inspector missed on a helicopter blade, and then stitch together multiple scans to determine the length of the defect, on the shop, in seconds! Users can also look at the 3D height maps of stitched images and select the scan from the stitch to execute our traditional 3D measurement analysis. This game-changing tool eliminates the need for additional equipment or manual measurement steps, and therefore significantly increases the speed of delivering critical information for the task at hand.

- 2D Measurements: Measure length, width, and distances, faster and with precision – even on stitched images. This update adds full 2D analysis capabilities to the existing ruler and drawing tools and supports toggling between 2D and 3D measurements in the same scan. Complete routine inspections in real-time on the line, thanks to GelSight Mobile’s portability and one-click reporting to the digital library.

- Rendering Engine: Enhancements to the rendering engine boost 3D image resolution and scanning speed and support the ability to customize color map ranges. Make more informed decisions with the new insights about the topography of surfaces.

GelSight

BOOTH 140

https://gelsight.com/

New Diatest High-Precision Bore Gages

Until now placing an internal bore gage inside a machine was expensive, complicated and slow. Worst of all the accuracy of such gages was limited typically providing a single size or an average based on a series of points. Today that is no longer the case, our new line automated gages mount right next to the rest of your tooling, no special setup. Our system measures the bore with up to .000010” resolution and collects the information including size, runout, min, max and more.

After taking readings we will store the results and perform offsets through your machine controls, we can even shut the machine down and alert staff if the machine will not run good parts. All these actions are performed without human assistance for a truly automated system. Choose between a family of handles that wirelessly communicate bore conditions to our line of interfaces, these gages provided fast readings limiting the reduction in cycle times, they can also be mounted outside the machines if you want to check parts post process.

Those post process readings don’t impact cycle time and can still be used to perform the offsets, sort parts and communicate via I/O modules with existing robots/cobots. The benefits of communication between machine results and staff also continue to exist should you want to run lights out operations and monitor results in real time. Learn more about all the features and checks we can perform at booth 242 where our Automation Team is waiting to show how the systems work and what features beyond bore diameters we can inspect.

Diatest USA

BOOTH 242

Diatestusa.com

Stotz Micro

The Stotz Micro measuring station is the ideal solution for precise and repeatable measurements in quality assurance. It combines user-friendliness, flexibility and maximum accuracy. With a repeatability of up to 0.05 µm and modularly expandable USB measuring boxes that support both pneumatic and inductive technologies, the Stotz Micro can be customized to your requirements.

Thanks to its compact design and quick changeover options, the measuring station is perfectly suited for dynamic, static and multi-point measurements such as coaxiality, inner and outer diameter and concentricity. The integrated software offers various license models for needs-based evaluations.

Stotz USA

BOOTH 145

www.stotz.com

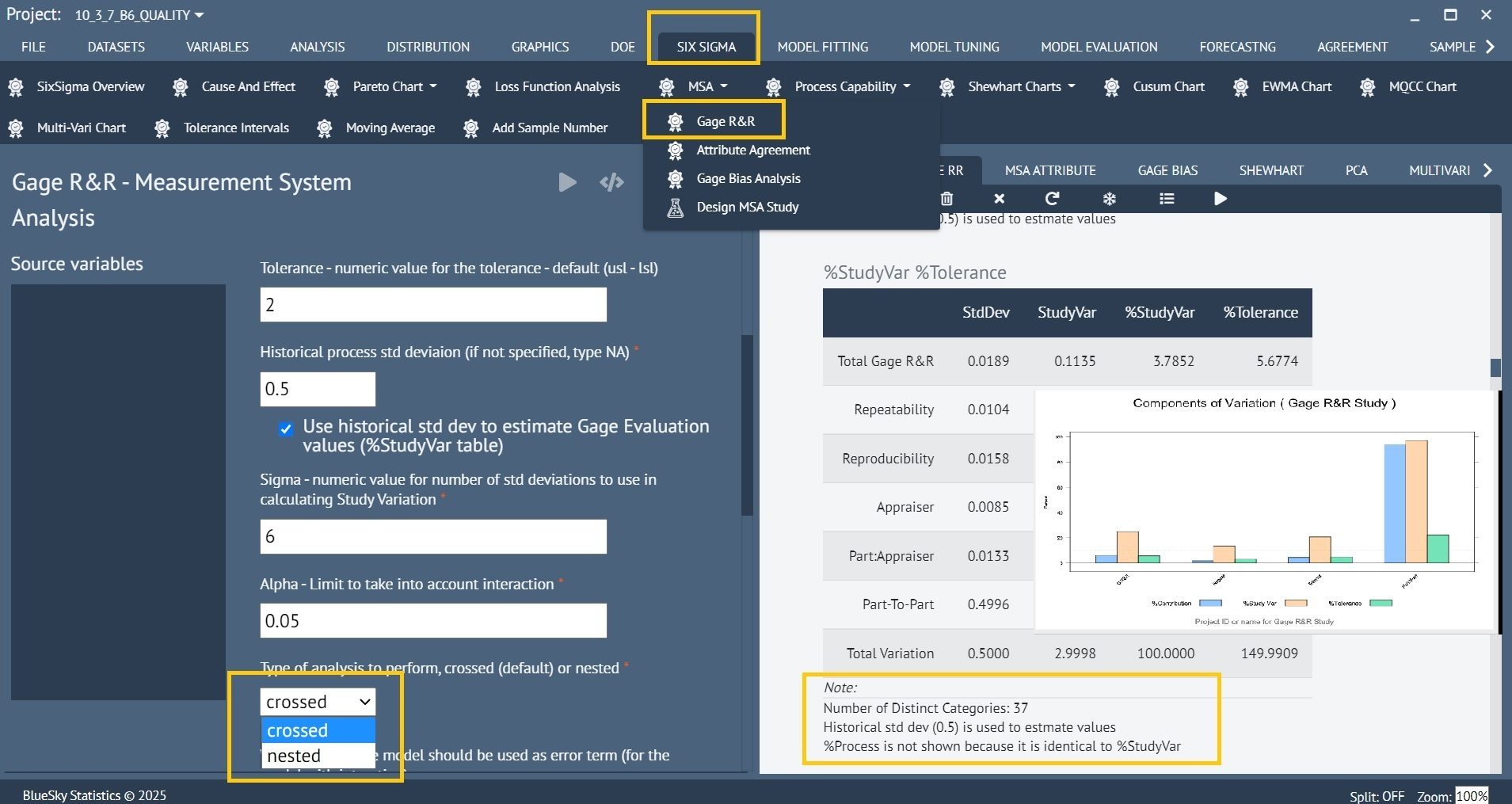

BlueSky Statistics

BlueSky Statistics, a powerful and intuitive statistical analysis software, is revolutionizing quality engineering and process improvement in the manufacturing industry to support all your process and quality improvement initiatives (well-known DMAIC methodology). Designed for professionals seeking robust statistical tools with an easy-to-use interface, BlueSky Statistics delivers a comprehensive suite of capabilities to enhance decision-making, drive operational excellence, and eliminate waste.

BlueSky Statistics leverages R, a widely used statistical software, to provide an unmatched depth and breadth of data analysis capabilities compared to other commercial statistical software in the market. BlueSky Statistics is tailored for engineers, analysts, quality and process improvement specialists, and Six Sigma professionals of all skill levels who rely on data-driven insights to maintain high standards of quality and efficiency.

BlueSky Statistics offers a broad range of statistical tools and analysis techniques essential for manufacturing professionals:

- Measurement System Analysis: Design and conduct Gage R&R studies, Attribute Analysis, Linear Bias assessments, and Design Gage Studies to ensure measurement accuracy.

- Process Capability Analysis: Analyze both normal and non-normal data to assess and optimize process performance.

- Statistical Process Control (SPC) Charts: Plot x-bar, R, S, p, np, c, u, I-MR, Mult-Vari, T-squared, EWMA, Cusum, and more to monitor process stability.

- Descriptive Statistics & Data Preparation: Clean, summarize, and explore data efficiently for in-depth analysis.

- Distribution Fit Analysis: Evaluate normal and non-normal distributions to identify best-fit models.

- And more

BlueSky Statistics

BOOTH 418

www.blueskystatistics.com

Who is TMI?

Started in 1991, Technical Maintenance, Inc. currently has 30 locations across the United States comprised of full service accredited laboratories and resident on-site technical service labs. There are plans to add additional accredited locations as required in the future.

TMI has consistently delivered full service calibration support to its customers in the government and commercial markets. With our comprehensive list of capabilities and our ability to be flexible, TMI has been able to partner with our customers to create customized asset management and calibration service programs to support each customer’s unique requirements.

TMI continues to maintain the highest level of Quality under our ISO/IEC 17025 accreditation which is written in a language relevant to the laboratory operations, meeting the principals of ISO 9001 and aligned with its pertinent requirements. All calibrations are fully traceable to the National Institute of Standards & Technology (NIST) and compliant to ISO 10012. TMI is accredited by ANAB to ISO/IEC 17025:2017, ANSI/NCSL Z540-1-1994 and ANSI/NCSL Z540.3-2006 with a broad scope of capabilities. TMI has a mastery of standard requirements in our customers’ industrial sectors (ISO 10012, ISO 9001, ISO 17025, and NADCAP).

Technical Maintenance, Inc.

BOOTH 504

tmicalibration.com

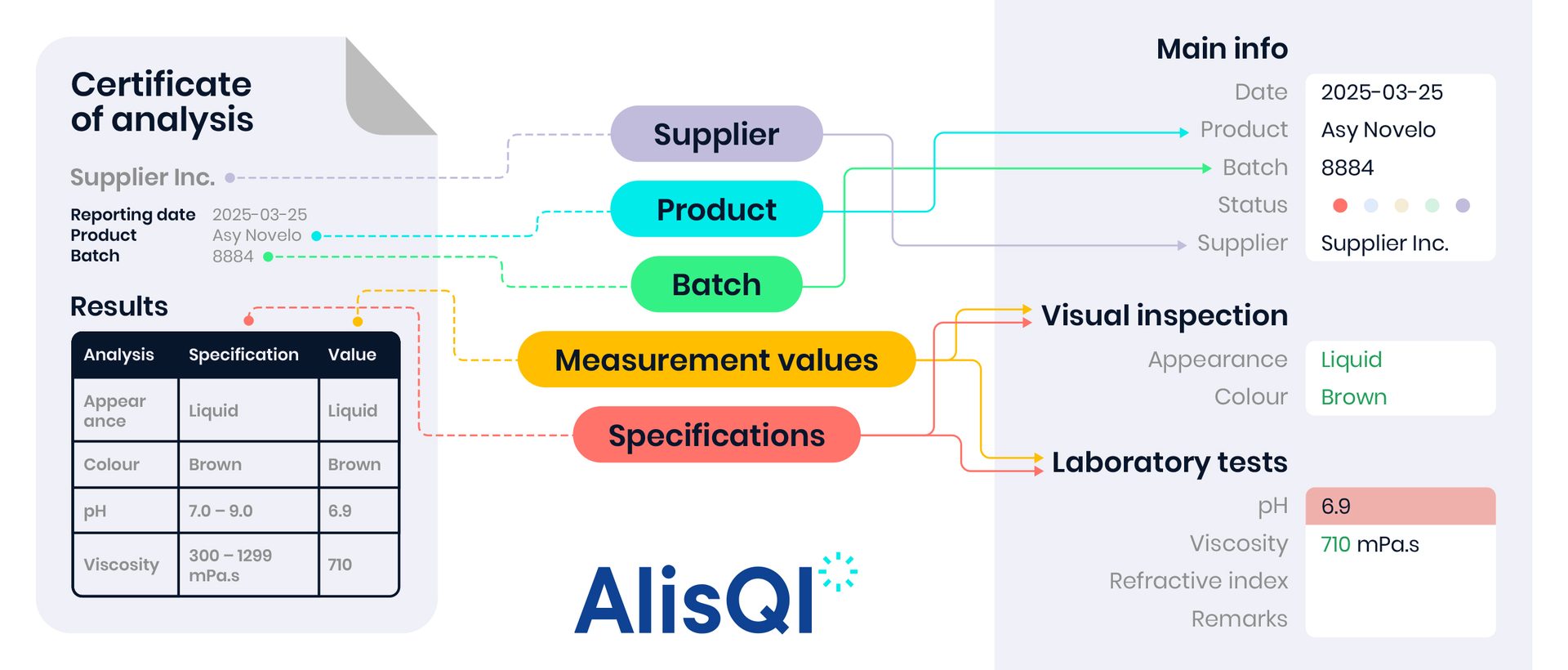

AlisQI Automatic PDF CoA Extraction Feature

Creating and managing Certificates of Analysis (CoA) must be one of the most tedious tasks within your quality team, so AlisQI proudly announces its automatic PDF CoA extraction feature. The big advantage for you as a user is that you do not need to define any parsing rules. You only need to specify the parameters that you want to extract, and our tool just delivers these parameters and their tolerances as documented on the COA.

This will help manufacturers take the leap towards the smart factory and it will improve quality professionals’ lives.

This modern technology allows for automated document handling, where incoming Certificates of Analysis are received and parsed automatically. This means you no longer have to manually assess incoming CoAs or retype quality results. It also translates into time savings and error-proof reports that can be generated with a few simple clicks.

How does parsing work? Well, all Quality Managers need to do is tell the system which data should be extracted from the PDF. But they do not tell the system where to find it, or how to extract it. That is what this technology solves for us. The measurement values and specifications will be extracted automatically, and stored into AlisQI so automatic non-conformity detection is triggered.

Through no-code platform you will be able to tailor your specific needs without requiring IT expertise. We provide you with a plug-and-play solution to enhance your understanding of supplier quality performance and save valuable time by automatically extracting data from incoming certificates of analysis.

Recap of features:

- Certificates of Analysis (CoA) are used to report the quality of products.

- Both the issuing of outgoing CoAs and the receiving and reviewing of incoming CoAs is traditionally time-consuming and complicated.

- With the smart QMS from AlisQI, manufacturers enjoy the advances of automation.

- The new automatic PDF CoA extraction feature is the world’s first.

- It eliminates the need for manual work, saves time, and promptly informs manufacturers of the quality of incoming goods.

AlisQI

BOOTH 244

https://www.alisqi.com/

Keyence Microscopes, Metrology Equipment

Keyence is a distinguished world-wide developer and producer of quality inspection equipment that includes digital microscopes and metrology systems. Our innovative products meet customer requirements in every manufacturing and research industry. Stop by our booth #237 for live demonstrations and to learn more!

Keyence Corporation of America

BOOTH 237

www.keyence.com

QI Macros for Excel

Automate Quality Improvement and SPC with QI Macros® Wizards and Templates. QI Macros is the fastest to learn and easiest to use. Just select your data, click a Wizard and that’s it!

QI Macros creates charts and improvement projects automatically. Download a free 30-day trial: www.qimacros.com/trial

QI Macros for Excel

Booth 409

www.qimacros.com

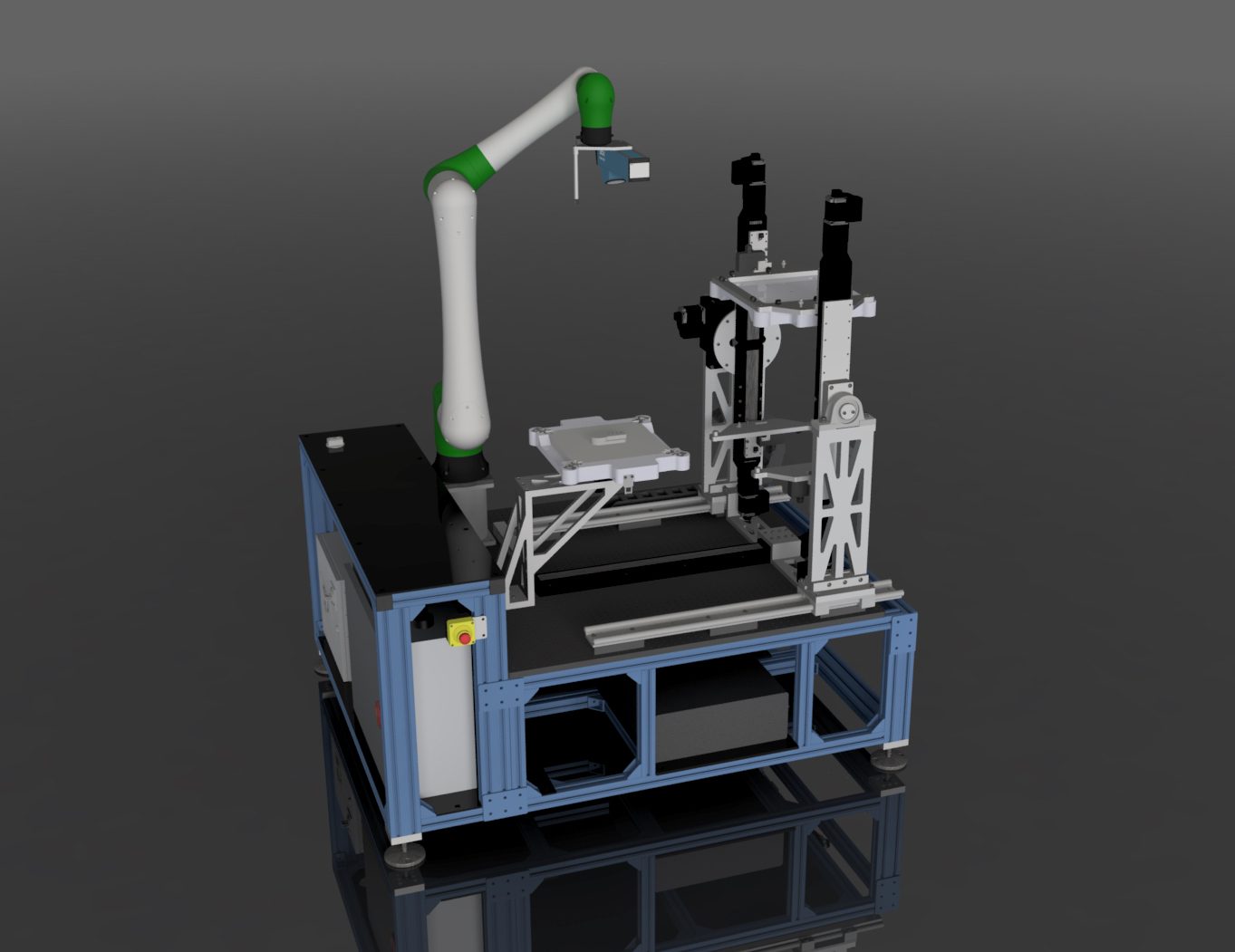

EZ Automation Systems PIQuE AI-Driven Inspection

EZ Automation Systems’ AI-driven inspection and robotic vision technologies. With a presence spanning the USA, Australia, Japan, India, Germany, Ireland, Switzerland, and the Czech Republic, the company is at the forefront of innovation in automated vision and industrial inspection.

EZ Automation Systems introduced PIQuE, a true 360° full-coverage AI-driven high-accuracy inspection system. Equipped with pre-trained models for rapid deployment, PIQuE is designed to flag all product defects with adaptive learning and intelligent customization, ensuring superior quality control across industries.

PIQuE's advanced AI capabilities allow it to continuously improve by learning from past defects and adapting to surface variations, ensuring unmatched precision and reliability. With seamless integration and scalability, PIQuE generates customized new product recipes, with minimum downtime for changeovers—a game-changer for high-speed manufacturing. Fully equipped with an AI agent to suggest quality metrics and inspection criteria based on the industry and the inspection history of the part, first of its kind in the market.

EZ Automation Systems

BOOTH 554

ezsystemsllc.com

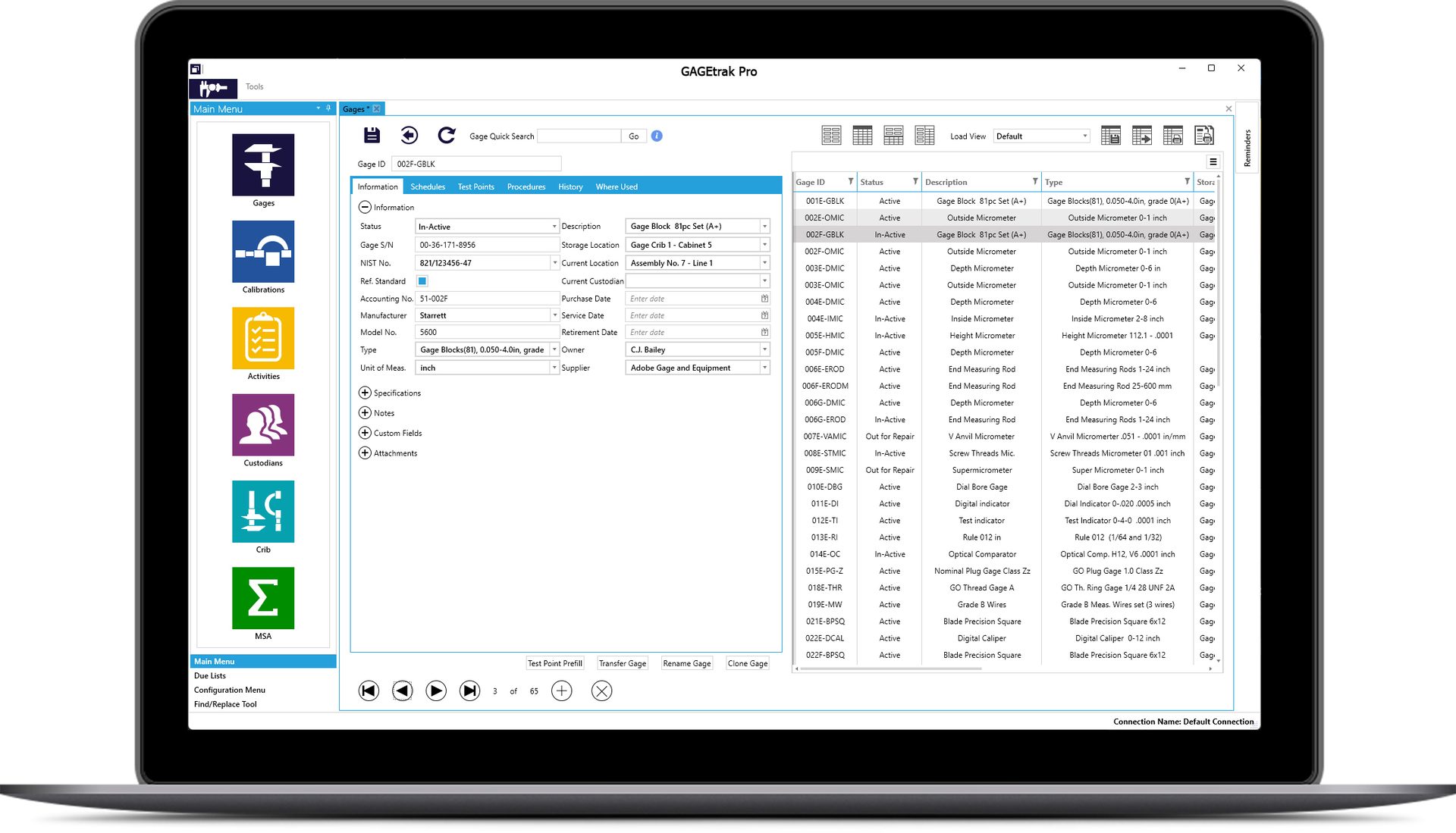

GAGEtrak by CyberMetrics

GAGEtrak continues to be the world standard for calibration management software, not only for its versatility, longevity and countless auditor recommendations, but also for remaining on the cutting edge of technology.

For over 35 years, GAGEtrak has developed a stellar reputation among auditors for its commitment to standards compliance. Among quality professionals, it is revered for its ability to suit every need and budget with its Pro and Lite versions, which offer different levels of calibration management.

GAGEtrak Pro’s feature set is quite extensive, from management of gages, staff, tools, suppliers, parts and service requests to monitoring scheduled and unscheduled calibrations, conducting gage R&R analysis (MSA 4th Edition) and so much more. Alternatively, GAGEtrak Lite’s feature set is more compact. It provides effective gage, calibration and procedure management as well as streamlined reporting, all within a simplified interface.

For organizations seeking to achieve Industry 4.0 readiness, GAGEtrak Pro and GAGEtrak Lite now have IIOT (Industry Internet of Things) and REST API capabilities, which can help align your calibration efforts with your organization’s technology goals. Now and well into the future, GAGEtrak is here to help you take your calibration management to the next level.

GAGEtrak by CyberMetrics Corporation

BOOTH 462

https://gagetrak.com

https://gagetrak.com/quality-show/

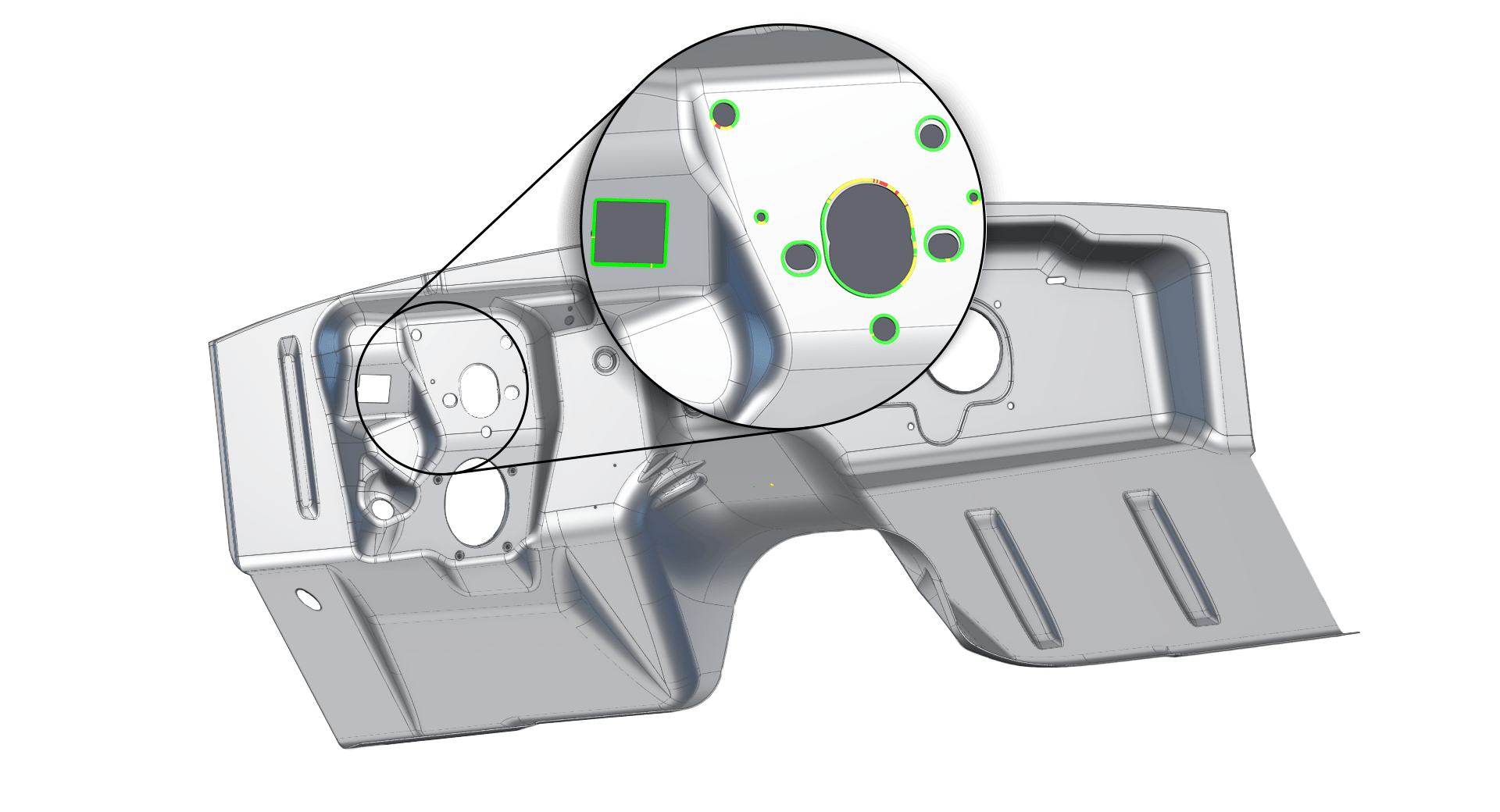

Creaform Metrology Suite

Creaform, a business of AMETEK, Inc., will showcase the new Sheet Metal Add-on as part of the recently released Creaform Metrology Suite. Designed to address industry specific needs, it tackles the many challenges of sheet metal inspection in the metalworking, automotive and aerospace industries. Providing measurements of sheet metal parts with never-before-seen accuracy and repeatability for 3D laser scanners, this software solution gives Quality Control (QC) and Quality Assurance (QA) professionals a higher confidence level in their 3D scan data, while empowering manufacturers to fully trust their inspection reports.

Previously a challenging endeavor, measuring thin sheet metal parts using 3D scanners used to be highly dependent on the users and the resolution settings. Now, however, the results generated by the new Sheet Metal Add-on are user independent. It quickly provides accurate and repeatable information on all sheet metal features, such as edges, holes, slots, rectangles, and trimmed edges. This specialized add-on provides the most flexible, complete, and simple measurement method, working in perfect synergy with the HandySCAN 3D|BLACK Series and all handheld MetraSCAN BLACK scanners.

It offers powerful new features and significant benefits, including:

- Accuracy and repeatability: Powered by advanced image algorithms, the Sheet Metal Add-on enables accurate and repeatable measurements that are independent from operator skills.

- Simplicity & flexibility: The measurement process is straightforward, requiring no additional hardware accessories and eliminating the need to navigate complex or overwhelming software parameters.

- Speed: The measurement process of the new Sheet Metal Add-on is up to 5 times faster than CMM processes.

- Intuitive interface: Includes a new visualization tool that allows users to validate that their data acquisition is ready for inspection before proceeding, saving time by removing unnecessary steps.

- Value for money: It offers a cost-effective alternative to expensive and time-consuming CMM solutions, ensuring a quick return on investment.

Creaform

BOOTH 429

creaform3d.com

PolyWorks by InnovMetric

PolyWorks® by InnovMetric enables manufacturers to scale up the use of 3D measurement data enterprisewide by lowering operating costs. InnovMetric, the independent software development company that empowers manufacturers of every size to digitally transform their 3D measurement processes, invites you to discover PolyWorks. This enterprise solution sets up a digital thread that lowers the cost of scaling up the use of 3D measurement data by deploying a universal 3D metrology platform and delivering 3D measurement data to engineering and manufacturing teams in real-time. The PolyWorks digital ecosystem accelerates the design, development, and validation of products and manufacturing processes. It also controls the quality of individual pieces and assembled products, and helps resolve manufacturing issues as soon as they occur.

PolyWorks significantly lowers the costs related to learning and operating 3D metrology software, managing large point cloud data files, and leveraging 3D measurement data within third-party reporting and analysis solutions:

- The user interfaces of the PolyWorks universal 3D metrology platform have been reengineered to let users perform inspection tasks and discover new tools intuitively, access frequently used tools more directly, and quickly find the functionalities that apply to selected objects. PolyWorks allows new users to learn and master basic workflows more easily, while seasoned users can strengthen their skills by exploring new tools at their fingertips.

- PolyWorks can manage vast amounts of 3D measurement data efficiently by using cloud storage, which is cost effective and delivers benefits such as instantaneous storage space increase and data file replication across multiple data centers.

- PolyWorks now offers plug-ins that interconnect its data management system to the Excel and Power BI industry-standard reporting and analysis solutions from Microsoft. Manufacturing organizations will appreciate the simplicity of being able to rapidly inject smart 3D inspection data into their favorite reporting tool, instead of having to train their internal experts at considerable cost on a third-party solution.

The PolyWorks|Inspector™ solution helps reduce time-to-market by measuring, controlling, and analyzing 3D dimensions at every stage of the manufacturing process. With this version, InnovMetric delivers major gains in efficiency through its re-engineered user interfaces. Users can now:

- Perform inspection tasks and discover new tools intuitively, thanks to a new ribbon menu and an improved interface widget organization that offers a more logical workflow

- Access frequently used tools more directly, thereby reducing mouse movements and clicks

- Quickly find the functionalities that apply to selected objects by accessing a contextual tab or a simplified contextual menu

PolyWorks|Inspector also offers new high-value tools and workflows:

- Surface datum features within datum reference frames

- Contextual control views to analyze surface deviations in multiple alignments and inspect dimensional controls in multiple coordinate systems

- CADless inspection workflows on CNC CMMs

InnovMetric

BOOTH 437

innovmetric.com