Products

the latest products to help you improve your manufacturing process

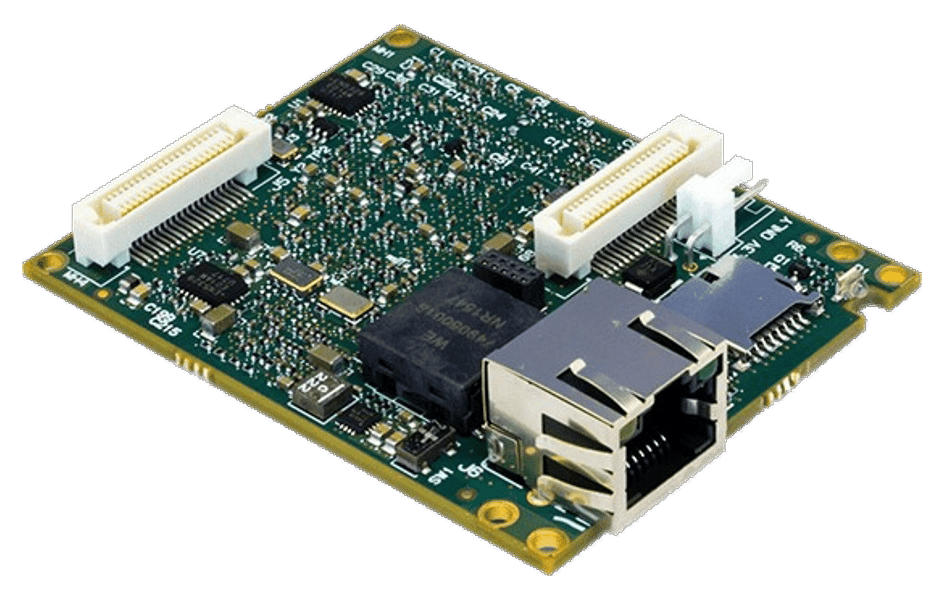

Pleora High-Performance GigE Vision Embedded Interface

Pleora Technologies introduced a new embedded interface that seamlessly transmits low latency GigE Vision video and data at 10 Gbps over flexible Ethernet cabling. Lead customers are now designing the iPORT NTx-Deca embedded interface into X-ray flat panel detectors (FPDs) for medical, dental, and industrial applications, contact image sensors, and high-performance machine vision cameras.

Compared with competing approaches that consume design time and dollars and divert development teams from critical system performance features, the iPORT NTx-Deca provides an off-the-shelf GigE Vision standard compliant solution that ensures interoperability in multi-vendor systems. Connect your sensor to the iPORT NTx-Deca, and the off-the-shelf solution seamlessly handles 10 Gbps video and data transport over flexible Copper Cat 6A Ethernet cabling for distances up to 100 meters. GigE Vision 2.0 compliance streamlines interoperability in multi-vendor imaging systems and applications.

The iPORT NTx-Deca integrates unique Image Management Database features to enhance system reliability. For high-reliability applications, such as medical and dental imaging, end-users can store video frames with associated metadata for patient identification, video replay, and traceability. In the event of a power or network failure, image management allows a user to retrieve data to ensure continuous and reliable inspection. The embedded interface supports IEEE 1588 Precision Time Protocol (PTP) to synchronize image capture and imaging system elements, with programmable logic controller (PLC) integration to seamlessly connect to and control critical manufacturing or inspection system components.

Pleora Technologies

https://www.pleora.com/machine-vision-automation/iport-ntx-deca/

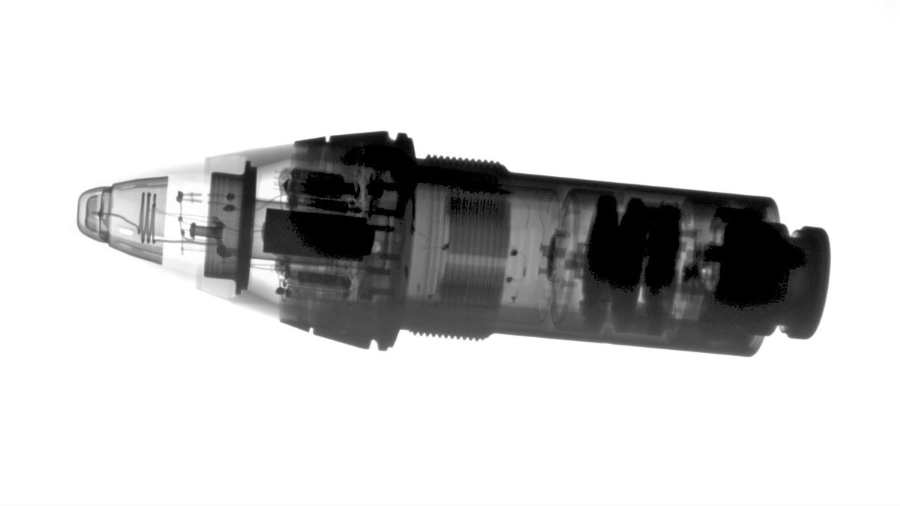

Scanna-MSC Portable X-ray Product Line

Scanna-MSC has launched its latest x-ray product family for the industrial nondestructive testing (NDT) market.

Scanna has designed a comprehensive range of ruggedized, portable digital radiography (DR) systems for NDT applications. By working closely with their customers, Scanna offers tailored solutions to meet specific challenges. Scansilc NDT x-ray systems are a packaged solution including a panel, generator, tablet/PC and software. Ideal for Mobile NDT applications such as pipe weld inspection, inspecting and decommissioning munitions.

For customers with their own generators, Scanna can offer panel-only solutions in a range of sizes from 97 x 233 mm to 860 x 860 mm (active area).

The integrated design of the Scansilc panels means fewer components and enables Scanna to offer smaller, lighter ‘on target’ systems. Scansilc NDT Imagers have near edge-to-edge imaging, and are impact and drop tested. These unique IP67 rated panels are designed for use in all weather conditions and provide protection from dust, mud, rain and even snow without any additional protective cover.

Scansilc NDT x-ray systems offer a best-in-class combination of high image quality and rugged field performance. They are designed to deliver reliable results very quickly, and can operate up to a full day on battery power alone. Scansilc panels are highly sensitive which means they can operate on lower x-ray exposure times without any loss of detail.

The slim form factor of the Scansilc Panels makes them suitable for sliding into tight gaps and can operate via cable or wire-free to allow for fast place and fire operation and full flexibility of movement. Without compromising reliability, Scanna’s portable, high-performance, DR x-ray systems offer durability and robustness which ensures image quality even in the most challenging environments.

Providing portable DR x-ray systems for NDT, Scanna are enabling their customers to keep their assets safe using preventative maintenance and assuring quality in manufacturing, production and in the field.

Scanna-MSC

www.scanna-msc.com.

PiL Sensoren Customized Ultrasonic Angle Sensors

With a new model variant of the proven sensor series P47, PiL Sensoren GmbH underlines its flexibility in the development of customized special solutions. The high-precision ultrasonic sensors are predestined for basic applications such as distance and level measurements in the measuring range up to 5,000mm and ensure reliable detection of even small objects due to their sound intensity. For demanding industrial applications with limited installation space, PiL has now produced a special version of the sensor for distances from 50mm to 500mm at the request of a customer. Instead of the conventional plastic housing, this sensor variant is equipped with a robust M18 stainless steel housing as well as a 90° deflection angle and complete shielding.

The manufacturer offers the ultra sonic device optionally with fixed or customized characteristic curve. The stainless steel distance sensor features a fast response time of 60ms, temperature compensation and a synchronization function for up to ten sensors, which is realized by connecting the HLD/Sync inputs. With the reflector angle screwed on, a significant reduction in the blind zone can be achieved in addition to sound redirection. The new stainless steel version, EMC-shielded according to IEC 61326-2-1 and IEC 61326-2-3, complies with protection class IP65 and withstands operating temperatures from -20°C to +70°C. The sensor head must be protected from direct contact with hot water above 50°C or steam.

PiL offers comprehensive application know-how and responds flexibly to customer requirements at all times. And where application-specific parameterization is not sufficient, the manufacturer is also happy to support its customers on request with individually customized solutions. The development and manufacturing facilities of the specialist for industrial ultrasonic sensor technology are in Germany.

PiL Sensoren GmbH

www.pil.de