Materials Testing

Inspection

NDT

Explained

Extensometry

An extensometer is a device used to measure changes in the length of an object, or sample in the materials testing world.

By Erik Schmidt-Staubach

Extensometry has been a major part of materials testing for almost 150 years, with only one major development coming in the early 1990’s. Wind tunnels, smart phones and Formula 1 are about to change all that.

An extensometer is a device that is used to measure changes in the length of an object, or sample in the materials testing world, such as stress-strain measurements and tensile tests.

The name comes from “extension-meter” which was invented to test strain on metal by Charles Huston, who described his device in an article in the Journal of the Franklin Institute in 1879.

To all intents and purposes this technology has been in use ever since. Today these devices are known as clip on contact extensometers, although more recent advances in automated testing have seen them largely replaced by a digital ‘sensor arm’ variety.

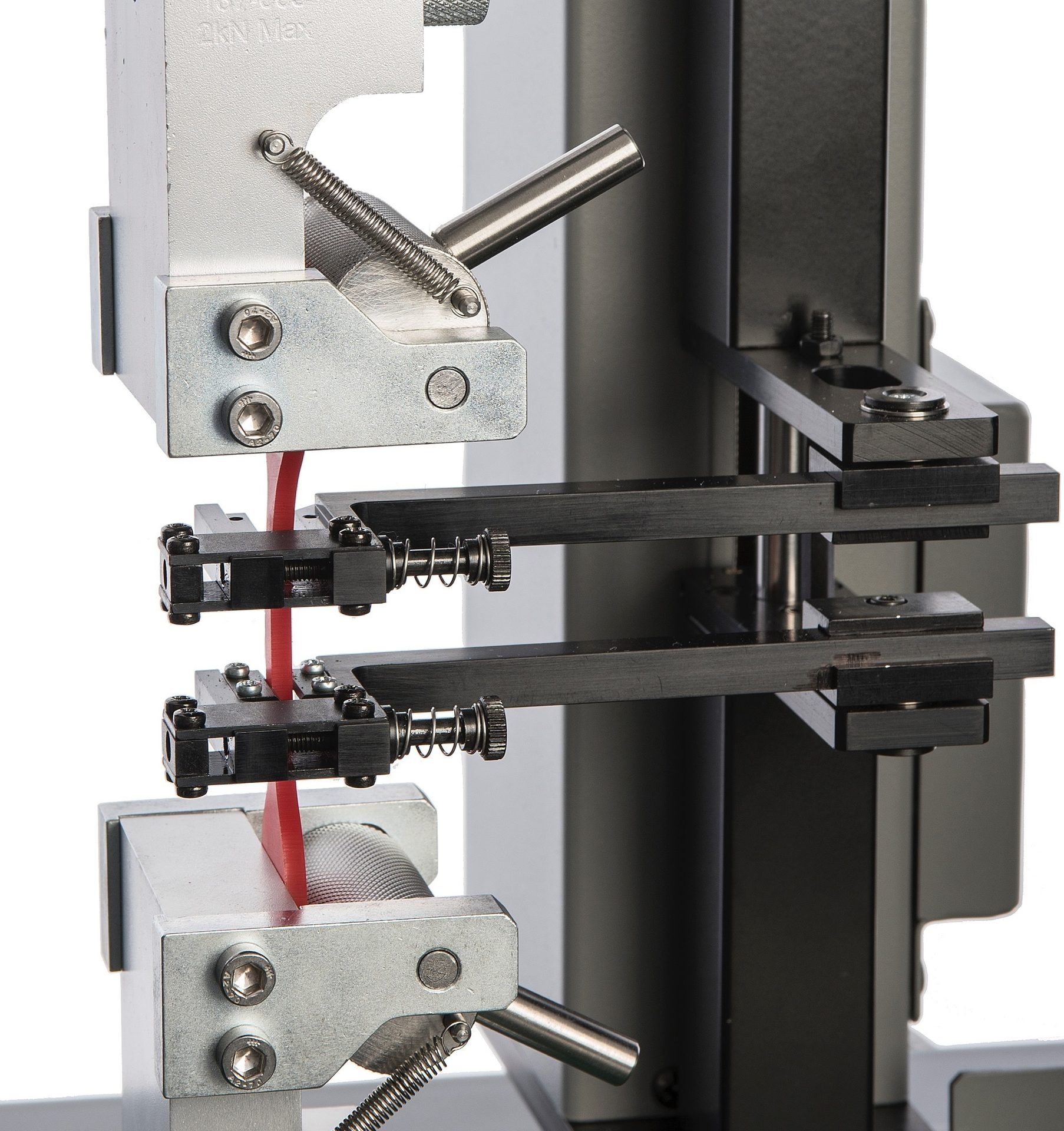

“Traditional ‘clip on’ extensometers are used for applications where high precision strain measurement is required, as in most ASTM-based tests,” explains Shawn Byrd, technical manager at Tinius Olsen and member of four ASTM committees.

“They come in many configurations and can measure displacements from very small to relatively large (less than 1mm to over 100mm). They have the advantage of lower cost and ease of use; however they can influence small or delicate specimens during a test.”

“The now more common sensor arm type can be applied to the specimen automatically by a motorized system and produce much more repeatable results than the traditional clip-on devices. They are counterbalanced and so have a negligible effect on the specimen, hence their popularity. But to all intents and purposes, the principle of this type of extensometer has remained unchanged for 150 years.”

The twin cameras of the new system cross correlate creating a 3D measurement volume, which is pre-calibrated and moves wherever you move or translate the head

A New Way of Doing Things

The early 1990’s saw the first real step change in this testing technology, with the development and introduction of the video extensometer (VE). These ‘non-contact’ instruments have several benefits over the contact variety, giving users more flexibility and the best available accuracy over a wide range of applications.

Benefits include no influence on the test specimen, negating errors due to worn or damaged parts or inertia from moving parts and no damage as a result of energy release at failure.

“A video extensometer is a non-contact strain measurement device that has no contributing influence on the specimen being tested,” continues Byrd.

“It works by measuring the strain on material samples. Specimens are often provided with lines, dots or various patterns of black-and-white marks. Sensors and software algorithms within the video extensometer detect the motion of these marks and thus the change in length and displacement during the test. It was groundbreaking in its day and is very much the preferred option when testing composite materials.”

VE technology’s biggest advantage is its versatility; it is very easy to use. One camera can be utilized for both longitudinal and transverse strain measurement, with just a simple alignment and adjustment of the test axis.

The groundbreaking Vector extensometer has a stereoscopic and volumetric system, with completely unique algorithms that allow measurements as fine as half a micron.

The technology enables numerous fields of view, in addition to multiple material and strain tests and real-time viewing and analysis. As no load is introduced into a sample, break and slippage from knife-edge engagement is not an issue.

“VE also solves many of the problems that can occur when a specimen has relatively soft edges, like a thermoplastic, or has features that can rupture or break, causing damage to a clip-on extensometer. Overall, VE provides users with a high-performance, high-accuracy and reliable solution for a host of test and measurement applications.”

Video extensometers are obviously the way ahead for the testing industry. Twenty years ago, 90% of extensometer applications were of the contact type. Today, it’s about 70% and, as the industry moves forward, it’s expected to drop down to about 20-30%.

In essence, the best choice for a particular material or application might not be the right choice for another. Keeping that in mind, and given recent improvements in both hardware and software, extensometer users need to seriously consider video extensometers based on their flexibility, versatility, reliability and cost-effectiveness over a wide range of materials and applications.

So, having established where extensometer technology is currently at, is this as far as its development can go or is there something out there that will take the instrument into the next 150 years? Let’s take a look.

The Future

The use of video cameras, allied to some very clever algorithms, tracks movement using digital image correlation (or DIC as it’s known in the industry) and has been around for some time.

These systems can be produced with bespoke measurement heads, integrated cameras, lenses and sometimes lights. Variations of these include single camera systems with integrated lighting and lens, as well as dual camera systems that work exactly the same way as your eyes. Both cameras cross correlate, creating a 3D measurement volume.

“This volume is pre-calibrated and obviously moves wherever you move or translate the head. It stays a fixed distance in front of it and enables you to measure a wide variety of things,” continued Byrd.

“This technology has been used to instrument wind tunnels, being used by the likes of Formula 1 teams as well as the aerospace industry. Typically, in these applications, they measure developmental designs of about a meter and a half in size in all three dimensions achieving micron level accuracy.”

For a wind tunnel operator this is hugely beneficial, enabling them to see how the car or plane is moving through six degrees of freedom in real time, with a very high capture frequency. Using multiple measurement heads, sharing a single coordinate frame, it can also isolate component movement from movement of the whole structure as it moves in 3D space. For example, deflection of a wing tip relative to the fuselage, even when the whole aircraft model is rotating.

Ever increasing demand for new and improved technologies within optics and video capture, such as those in mobile phones, enabled huge improvements to be made by massively simplifying the onboard processing and ease of use, as well as reducing the physical size of each unit.

“This extensometer has a stereoscopic and volumetric system, with algorithms that allow measurements as fine as half a micron. It has a very quick and concise alignment process with lasers that allows for a finite view of the sample in the volumetric window that the device captures,” explained Byrd.

“The technology is not strictly speaking digital image correlation (DIC) but it falls under the same general umbrella. It is the same principle in as much as it is tracking movement of a portion of the specimen by using DIC techniques, which is basically pattern recognition, recognizing the pattern frame by frame and tracking it.”

“DIC systems have a sort of stress or strain map that looks a little bit like an FEA plot but this adaptation has an actual point to point measurement between two points on the specimen. So, as I said, it’s not strictly speaking DIC but it’s a very similar technology.”

“As an example, elongation tells us a lot about a material but there are a lot of things that can affect this such as the speed of testing, the specimen, geometry, some different heat elements that may be generated, the surface finish of the sample that is being tested and the alignment of the device.”

“As such, this step change in extensometry has integrated a very quick and concise alignment process, with lasers, that achieves a finite view of the sample in the volumetric window that the device captures.”

‘But one of the biggest step forwards with this technology is the speed of use. It takes away the need for time-consuming setting up and calibration of existing clip on extensometers,” says Byrd. “It really is a case of simply plugging in and testing.”

Image source: Tinius Olsen

Ian R. Lazarus is president and CEO of Creato Performance Solutions, providing leadership development, training, and solutions to support operational excellence.

Jim L. Smith has more than 45 years of industry experience in operations, engineering, research & development and quality management.