Industry 4.0

Integrating QC and QA can mitigate product quality risk and empower smarter factories. By David Isaacson

Connected Quality Is the Secret Sauce to the Fulfillment of Industry 4.0

The manufacturing industry has seen major upheaval over the past few years. From supply chain disruption to worker shortages, keeping the pipeline filled with quality products – free of defects – has been no easy challenge.

Because of these issues, the promise of Industry 4.0, or smart manufacturing, has never been more important. Industry 4.0’s factory floor of tomorrow is one that will be operational 24/7/365, self-sufficient, autonomous and driven by advanced technology and automation fueled by real-time data.

The fulfillment of Industry 4.0, as well as any digital transformation goals, are predicated on the ability to collect, analyze, deliver and act upon enterprise-wide data – not just data on the manufacturing floor. It must come from all points in a fully connected and integrated manufacturing ecosystem that extends beyond the shop floor and into the “top floor,” the C-suite. Data residing in product design and engineering departments, finance, human resources, as well as data from suppliers, logistics partners and customers – all play a part in the data ecosystem.

Connected quality across the enterprise facilitates the flow of actionable data across departments and functions to enable faster, more informed decisions.

Connecting the Dots Between QC and QA

The problem is that much of the data continues to be siloed in disconnected systems. And, one of the biggest data gaps is between quality control (QC) and in-process quality assurance (QA).

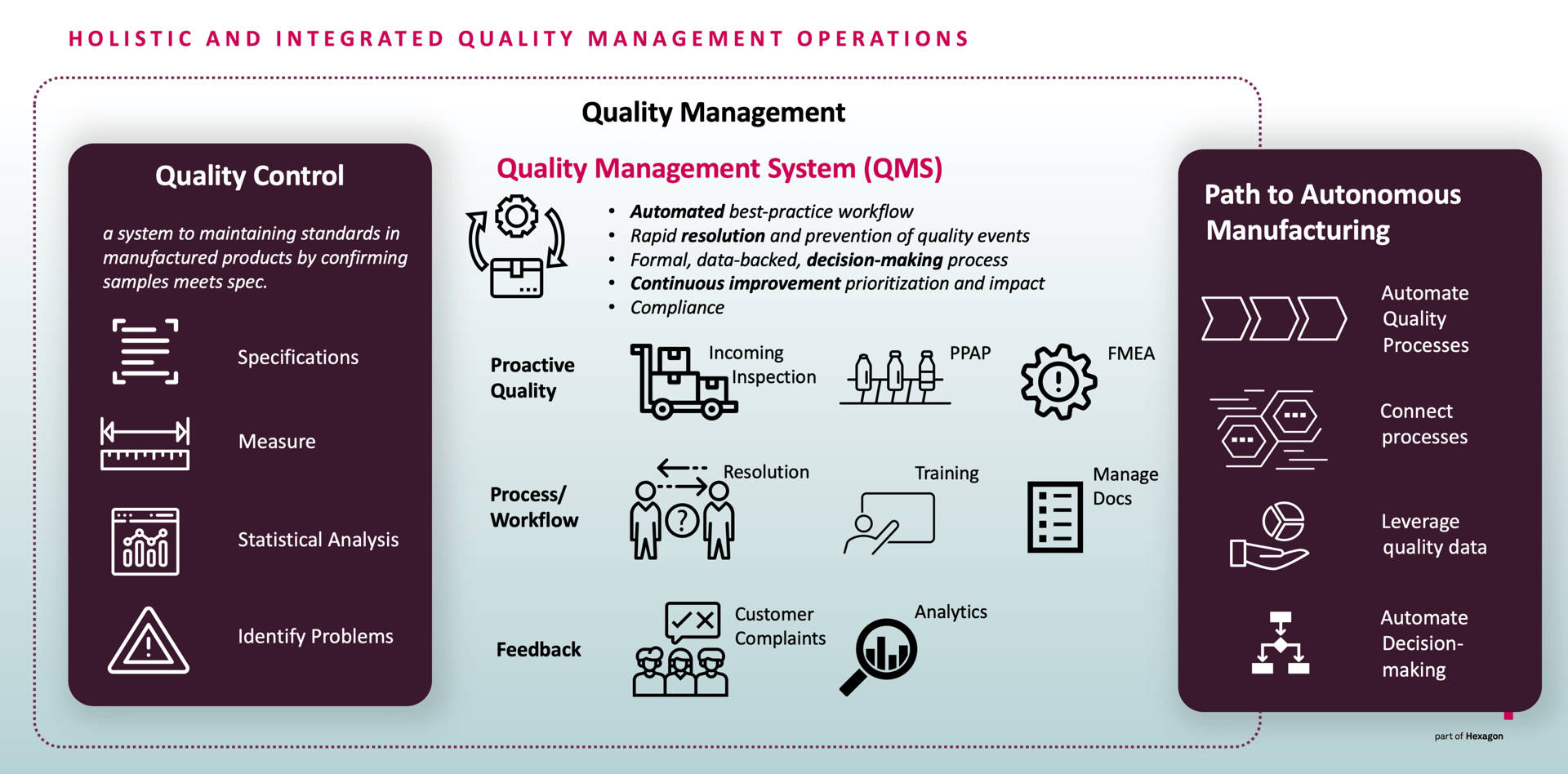

While both are focused on quality, there are distinct differences between QA and QC. Quality control is often focused on the shop floor and involves specific protocols for measuring, testing and inspections to ensure that a manufactured product adheres to specifications and a defined set of quality criteria. It addresses quality at the machine level, operator level and product level. Quality assurance, on the other hand, involves every step in the process to identify and proactively mitigate quality issues and risk across the enterprise and externally with suppliers. However, both have the same ultimate goal – deliver quality products to customers.

To truly empower Industry 4.0, there must be an integrated digital connection between QA and QC so that quality is addressed at every step of the product lifecycle – from design to manufacturing and delivery. The challenge lies in the fact that while QC and QA data reside across the enterprise, often existing systems are not scalable and they aren’t integrated so they can’t share data with other systems, limiting feedback and the ability to quickly react to quality issues as they arise. And too often, a “checklist” mindset to quality has arisen in which companies do just enough to stay ahead of increasing regulatory burdens.

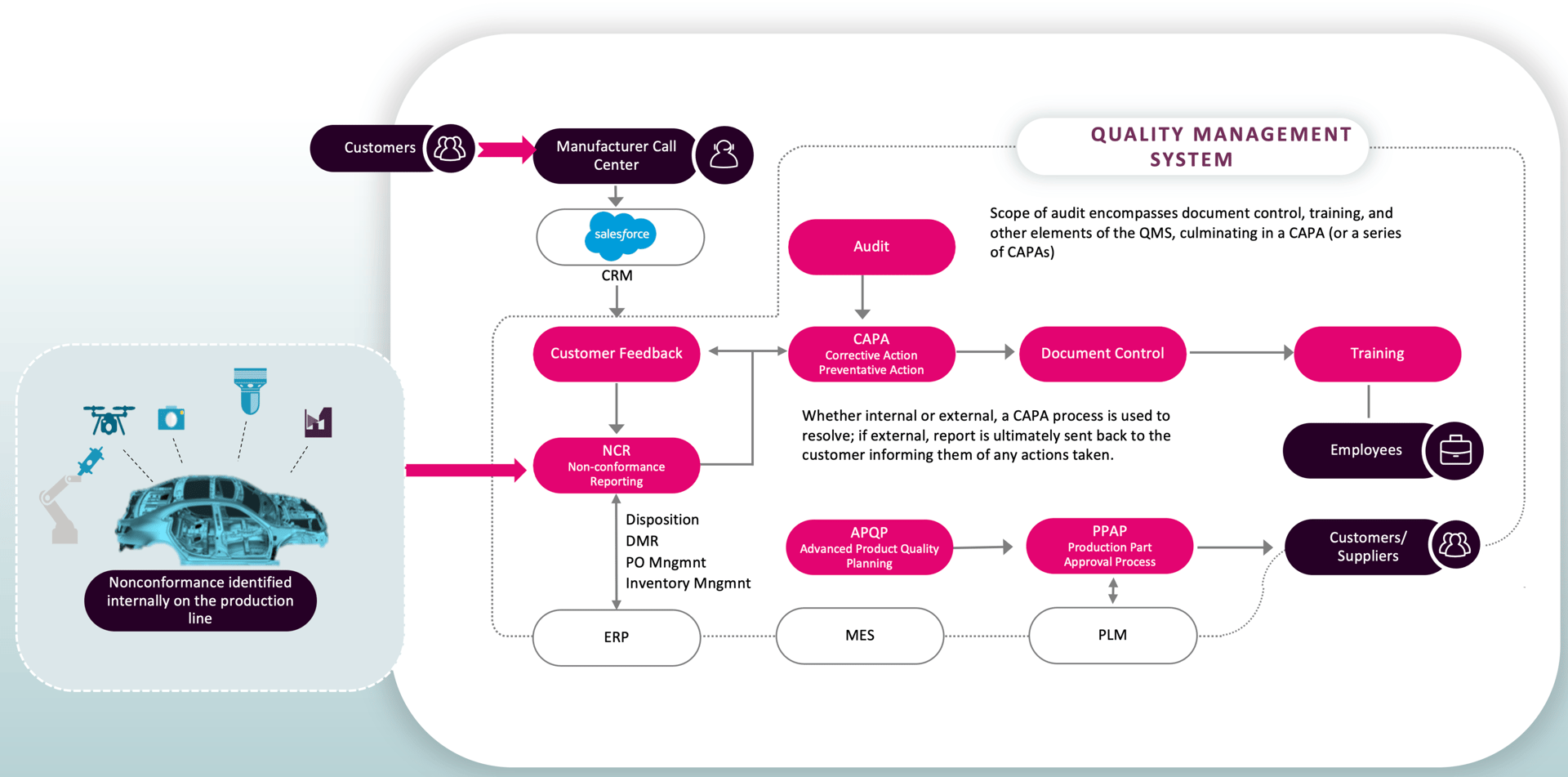

With all the different systems in use from design to delivery, it can seem like an insurmountable task to share data and derive insights. The goal of connected quality is to enable improved decision-making for both autonomous and manual manufacturing. Integrating the QMS with systems used on the shop floor and other enterprise systems (such as ERP) facilitates the flow of data and the ability to make more informed and even automated decisions.

Enterprise-wide quality can be more effectively addressed by delivering QC data to a comprehensive QA software platform (the quality management system). This type of integration can catalyze a virtuous cycle of continuous improvement, addressing quality concerns earlier in the manufacturing process.

Connected quality can have significant benefits. QC tools can identify a quality event or non-conformance that if not caught can present itself across the product lifecycle. The quality management system (QMS) manages and accelerates the disposition process, including notifying other key systems, such as an ERP. Issues can be captured in one place to perform root-cause analyses across a diverse and comprehensive data set. Regardless of where a problem originates, all quality issues need to come into one place to determine if they are one-time or systemic issues, identifying a common root cause.

Connected quality across the enterprise facilitates the flow of actionable data across departments and functions to enable faster, more informed decisions.

Wabtec Sees the Big Picture with Quality Integration

To bring the importance of integrated QC and QMS to life, consider the case with Wabtec, a leader in rail technology. The company initially had a problem with a disconnect between QC and QA data. It struggled with multiple, disparate quality management systems across more than 60 locations. The siloed information made it difficult to promptly and accurately address quality issues across the company, as well as its complex supply chain.

Leveraging a unified QMS, Wabtec consolidated multiple applications into one, providing insights to production staff and business leaders, allowing them to gain a unified view of enterprise-wide quality data. It also enabled the company to more effectively identify the source of product defects and comply with regulatory standards and frameworks.

Before Wabtec connected QC and QA, it had limited visibility into how much rework was occurring and how exactly rework decisions were being made. Defects slipped through the cracks because of a lack of traceability, and Wabtec was unsure when and where in the process problems occurred. In addition, some nonconformances were subjectively and manually entered into the system, which opened the door to human error.

By integrating QA and QC, Wabtec has greater insight into quality data, can easily launch a nonconformance report, and by avoiding the need for manual data entry, they have streamlined issue resolution tracking, and eliminated the potential for human error. The resulting financial benefits have exceeded all expectations, with a $30M improvement in cost of quality and 25% reduction in defects.

Manufacturers rely on their shop floor QC data, along with the process and workflow data contained within their QA systems, to mitigate quality risk and identify problems. Integrating QC with QA provides a complete quality picture – from design through delivery. Only through connected quality will manufacturers gain the data-driven insights that will allow them to truly realize their digital transformation goals and the promise of Industry 4.0