Products

the latest products to help you improve your manufacturing process

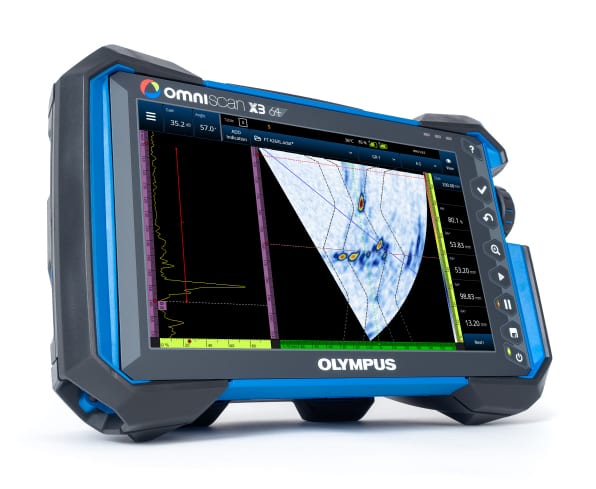

Olympus OmniScan X3 64 Flaw Detector

The new OmniScan™ X3 64 flaw detector delivers improved power and performance to Olympus’ field-proven phased array ultrasonic testing (PAUT) product line. This 64-channel instrument has the pulser capacity to drive phased array (PA) probes with a larger number of elements, increasing the data acquisition speed for total focusing method (TFM) imaging. Users can exploit its increased capabilities to expand and diversify their application portfolio.

The high portability and enhanced performance of the OmniScan X3 64 flaw detector increase inspection productivity. It can process TFM images up to four times as fast as its predecessor,* yet comes in the same rugged and easily transportable box. On job sites with limited or restricted space, users will appreciate that the OmniScan X3 64 unit is compact and less cumbersome than other 64-channel devices. Inspectors can also remain on site longer and perform bigger scanning jobs without transferring data, thanks to the large 1 TB onboard storage.

Facilitating complex and thick part or weld applications, the instrument’s full 64-element aperture PA and 128-element aperture TFM enables users to optimize advanced Dual Linear Array™ (DLA) and Dual Matrix Array™ (DMA) probes. To save time during setup, all models in the OmniScan X3 series have integrated DLA and DMA support.

Smaller defects are easier to distinguish using the OmniScan X3 64 flaw detector’s high-resolution PA and TFM imaging. Accommodating lower frequency probes, the OmniScan X3 64 unit can increase penetration in attenuative materials while reducing signal saturation. These improved detection capabilities assist monitoring for early-stage flaws, such as high-temperature hydrogen attack (HTHA).

When applications require advanced analysis, the entire PA inspection workflow can be performed using Olympus’ WeldSight™ software for greater efficiency. With the WeldSight Remote Connect app installed on the OmniScan X3 64 unit, users can instantly view the acquired data on a PC, exploiting the customizable user interface and software tools that facilitate specialized inspection procedures, including new-fabrication welds in pressure vessels.

* Results obtained using a 64-element probe, compared with an OmniScan X3 32:128 model.

Olympus

www.Olympus-IMS.com/phasedarray/OmniScan-X3

www.Olympus-IMS.com/WeldSight/

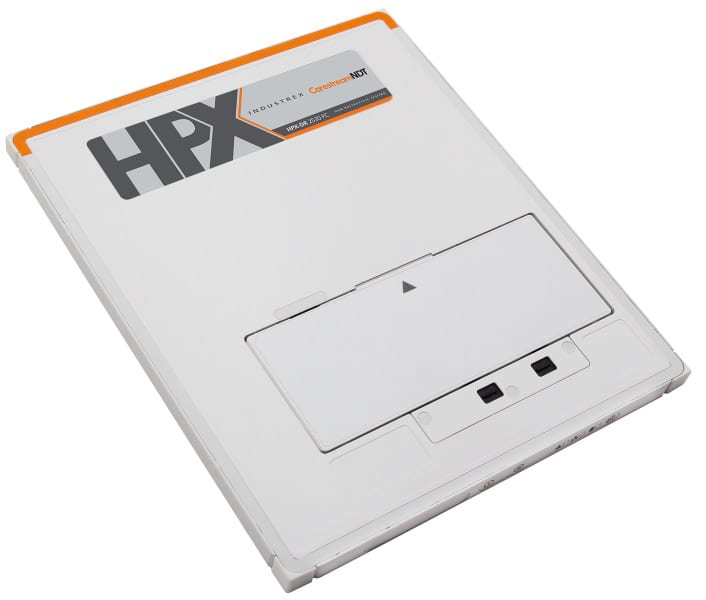

Carestream NDT Non-Glass Compact Detector

Carestream’s Non-Destructive Testing (NDT) group has released the HPX-DR 2530 PC, a non-glass detector that enables faster throughput for imaging, as well as rapid analysis and reporting. The durable non-glass design is built for the tough conditions of NDT work, especially portable radiography.

With a 145 μm resolution, the HPX-DR 2530 PC provides highly detailed imaging for analyses and reporting. Its compact size of 250 x 300 mm and thin profile at 14.7 mm allow the detector to fit in smaller spaces, enabling imaging in confined areas. The non-glass design virtually eliminates expensive and time-consuming repairs while increasing utilization, uptime and productivity. The detector comes with tungsten shielding allowing a higher cumulative dose while preserving image quality, increasing panel life and usage. With the HPX-DR 2530 PC detector, critical defects can be evaluated and reported with confidence while increased processing speed and productivity help perform more inspections in less time.

The HPX-DR 2530 PC detector works with Carestream’s INDUSTREX Digital Viewing Software. The INDUSTREX software suite operates seamlessly across all Carestream NDT computed radiography (CR) and digital radiography (DR) modalities. Customers can easily add the new detector to their tool set of imaging equipment without having to purchase and learn new modules.

Carestream NDT

http://www.carestream.com/nondestructivetesting.html

Teledyne Flir 12MP Blackfly S with On-Sensor Polarimetry

Teledyne Flir introduced the latest addition to its polarized Blackfly S GigE camera lineup – the BFS-PGE-123S6P-C.

This new 12MP model is well suited for applications dealing with reflective and/or challenging lighting conditions. Ideal for use cases like traffic systems, UAS (unmanned aerial systems), inspection lines with transparent or reflective parts, and other uncontrolled lighting environments.

The camera pairs the new Sony IMX253 MZR sensor with an easy-to-use glare reduction feature built into the Spinnaker SDK, making application development and deployment fast and easy. These new GigE cameras with Power over Ethernet (PoE) also take advantage of the new Lossless Compression feature, delivering up to 14 FPS at full resolution without compromising on image quality. Weighing in at just 36 grams, it is significantly lighter and more compact than competing offerings in the market.

Detailed specs include:

- 12 MP Global Shutter CMOS featuring on-sensor polarimetry

- Delivers resolution of 4096 x 3000 @ 10 FPS (up to 14 FPS with Lossless Compression enabled)

- Smallest and lightest: 29 x 29 x 30mm, 36 grams

- Spinnaker SDK can dynamically reduce reflections from non-metallic surfaces

- Long distance cable options for unique application setups

- Features Power over Ethernet (PoE – GigE)

Teledyne Flir

https://www.flir.com/

Xiris' New CellView Camera

Xiris Automation Inc. has released the Xiris CellView camera that provides a wide-angle view of automated or manual welding cells, allowing welders and supervisors to remotely monitor the welding status during set-up or while in progress to help improve the productivity of each welding cell.

When used in combination with Xiris open-arc weld monitoring cameras, the CellView camera can be particularly useful for remote welder instruction, supervision and training. The instructor can review both the trainee’s form and up-close weld parameters to ensure the trainee is achieving optimal quality welds. Additionally, the camera can be used by the instructor to record their own welding form and the details of a weld demonstration to playback to students.

These are just a few of the many benefits that the Xiris CellView camera can provide by being able to capture a wide-angle view of the welding cell as a result of features such as low-level light sensitivity, auxiliary lighting, adjustable zoom, robust housing and compatibility with the Xiris WeldStudio™ software.

Xiris Automation Inc.

www.xiris.com