Eddy Current

Inspection

NDT

By Jesse Herrin

The Big Deal

about ECA

With the latest instruments and probes, eddy current array strikes a balance in speed, POD, and cost effectiveness on big jobs.

To a qualified and well-equipped nondestructive testing technician, few inspections present an insurmountable technical hurdle. Technicians have a range of testing methods at their disposal, from sophisticated ultrasound and eddy current technologies to manual processes like liquid penetrant.

Often the bigger challenge isn’t the technique but the sheer size of a work area. The scope of any inspection will affect the technician’s approach to speed, flaw detectability, and ultimately cost—all high priorities for a manufacturer or asset owner.

For instance, penetrant testing (PT) is a simple technique to identify surface-breaking defects and discontinuities in metal and other nonporous materials. In a localized area, PT can be affordable and efficient. However, it requires chemicals and extensive surface preparation, including the removal of paint and coatings. The time and cleanup involved are compounded in a big work environment.

Conventional radiography uses X-rays or gamma rays in combination with film to indicate welding flaws and defects. The image quality will depend on ease of access to the test area, and using radiation at the job site is an obvious concern.

With a portable phased array ultrasonic testing (UT) instrument and dual (2D) matrix array probe assemblies, technicians can build efficient scan plans, conduct lateral scans and create three-dimensional representations of the weld, and detect mis-oriented and transverse flaws in lap and butt welds. Covering the entirety of a weld requires multiple beam angles, however, which can add steps to the inspection process. Furthermore, surface-breaking cracks can be difficult for UT to detect and size.

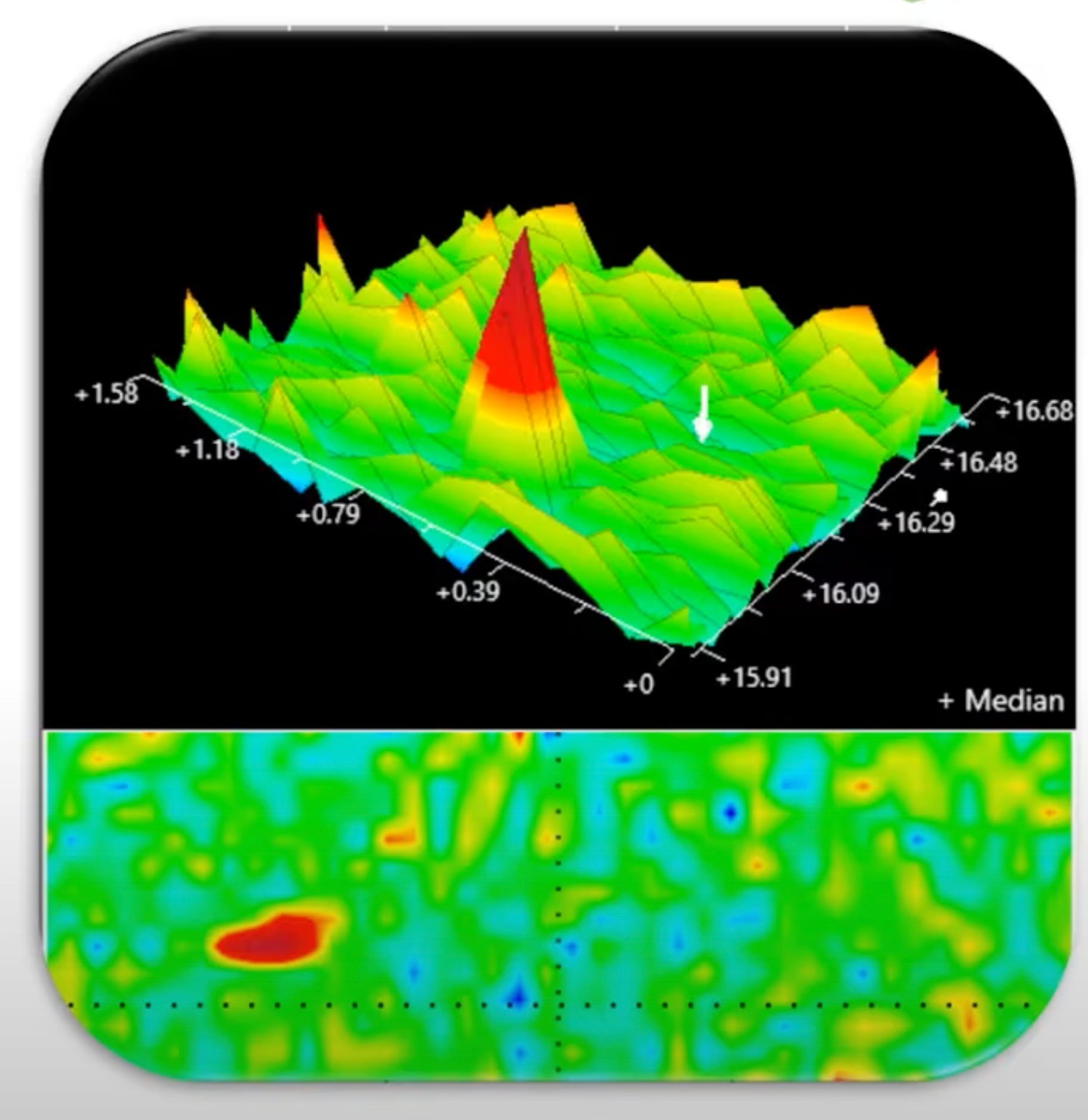

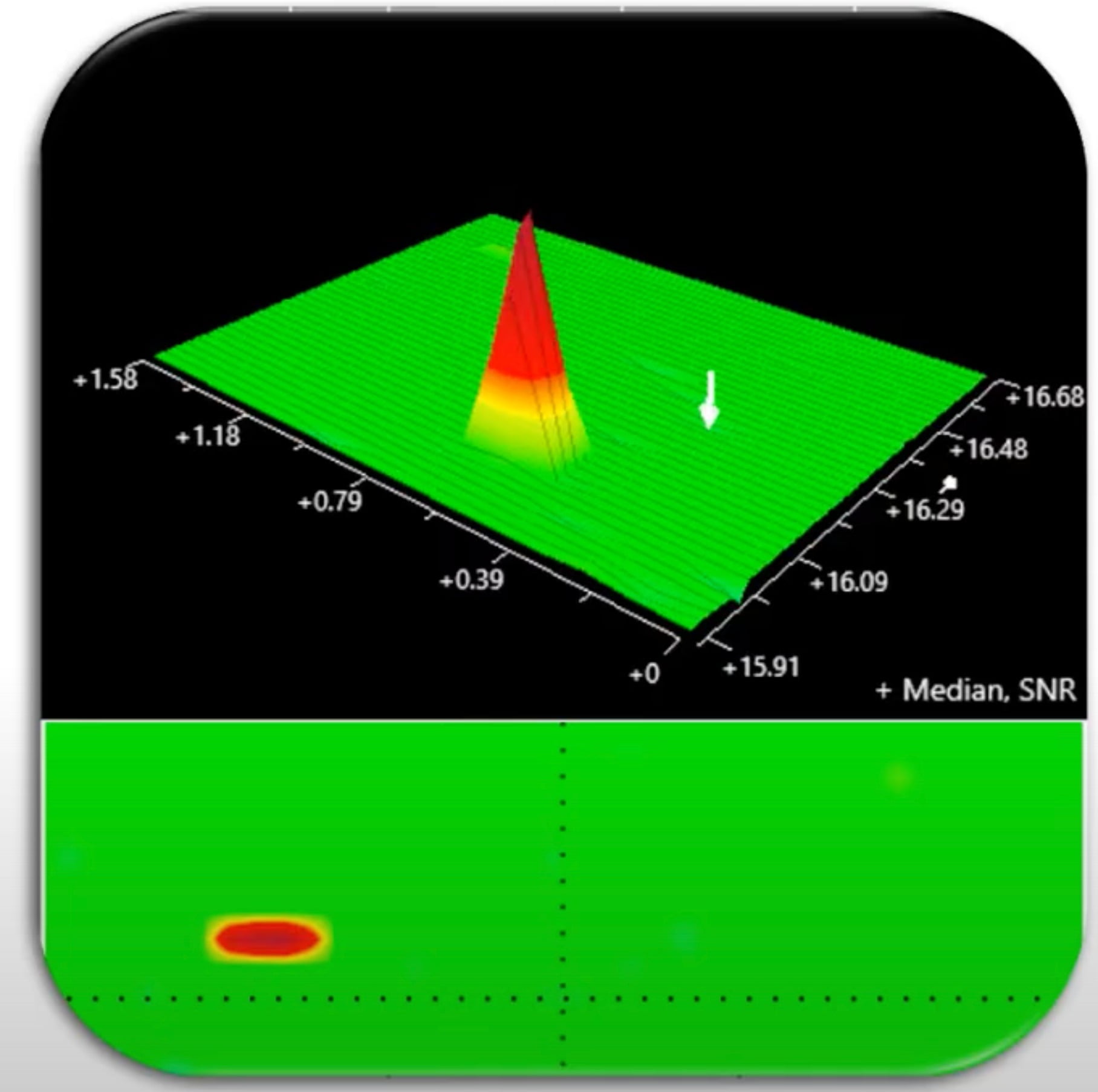

These are examples of low and high SNR in an eddy current C-Scan. Source: Zetec

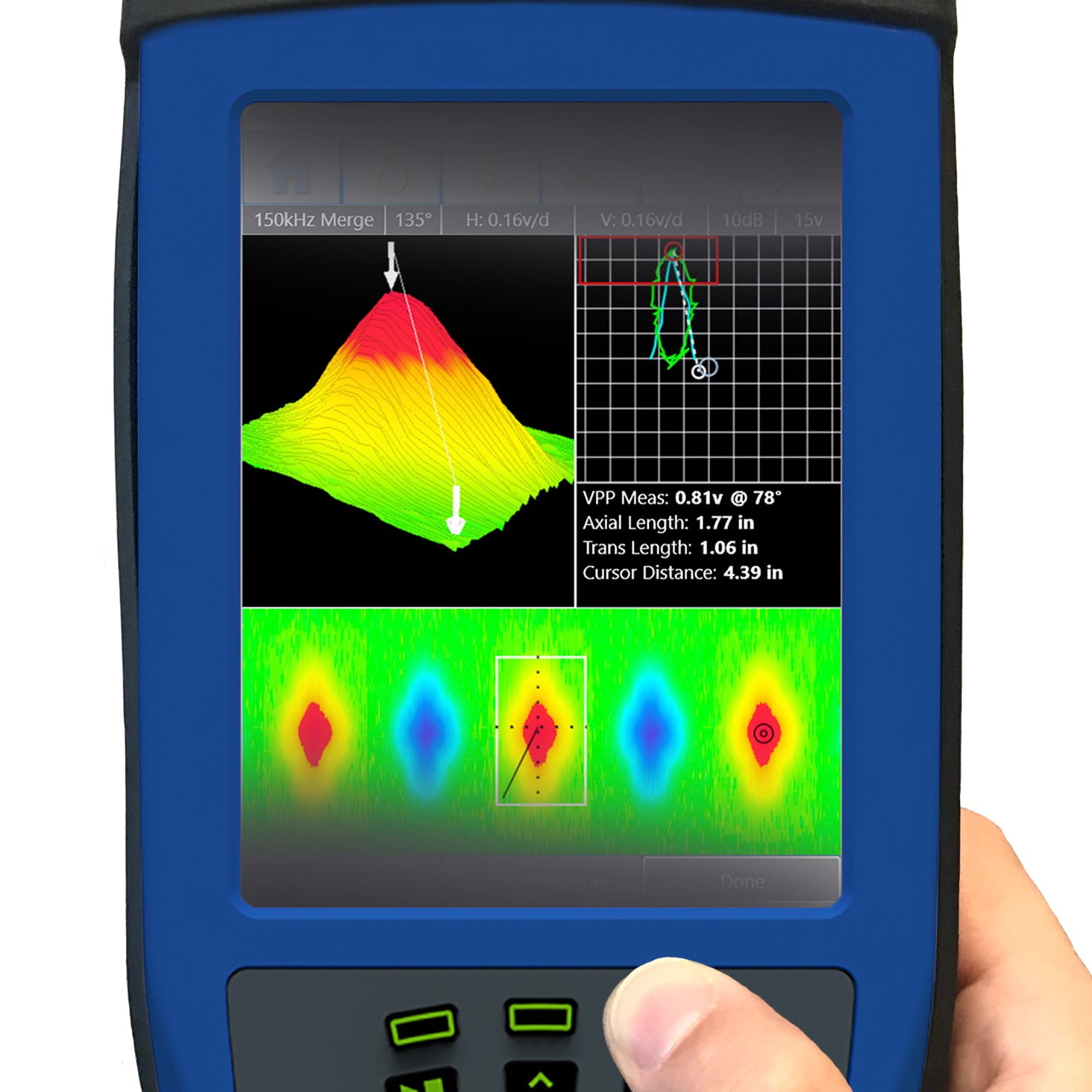

The C-Scan capability of the latest handheld ECA tools provides instant visual feedback to the technician. Source: Zetec

ECA advantages

Eddy current array (ECA) is an effective technique for detecting surface and subsurface indications in ferrous and non-ferrous materials, including cracks, pits, corrosion, and damage due to impact or fatigue, and requires no surface preparation or handling of chemicals.

The newest generation of portable eddy current tools has dramatically increased test speed, accuracy, and repeatability, especially on long weld runs and large inspection areas. These handheld instruments have the processing power, software, and battery life to perform inspections virtually anywhere. Their C-Scan capability provides instant visual feedback to the technician, and they produce digital records of inspection that can be stored, analyzed, and compared against a history of results.

One practical limitation of ECA technology is that as the operator moves the probe across the surface under test, the excitation coils need to be close to the material for accurate flaw detection and signal quality. A flexible probe can conform and adapt to different surfaces and contours while keeping the excitation coils and sensing devices closely and properly aligned as the technician slides it over the surface.

Understanding SNR

The signal to noise ratio or SNR compares the level of a desired signal to the level of background noise in the scan. A low SNR limits the ability to detect the very small flaws and loss of material that can occur in friction stir welds and multi-layer structures.

With ECA, there is a direct relationship between scan speed and SNR. As scan speed increases, the SNR decreases; conversely, slower scan speeds are more likely to raise the SNR and produce the required probability of detection (POD). Bolt-hole data is notorious for noise, which can come from many sources, such as the motor of the scanner, out-of-round holes, or holes that are not clean.

The question becomes how to balance an efficient scan speed that will produce the required POD while completing the inspection in a cost-effective manner compared to other nondestructive testing methods.

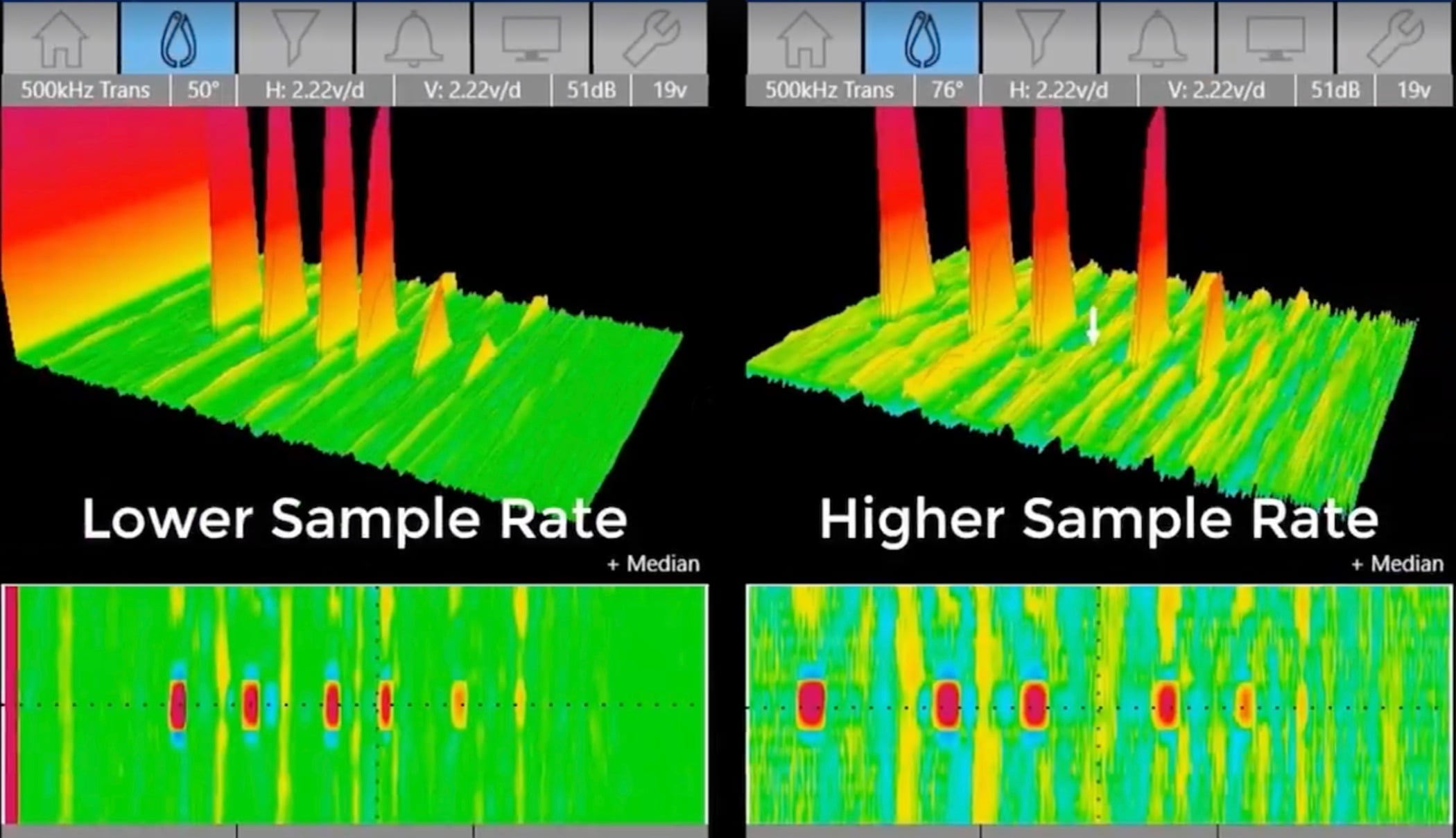

The theoretical maximum scan speed for an ECA probe is the time-slot rate (TSR) divided by the product of the spatial resolution (SPR) and number of time-slots (TS). A common SPR is 2 samples/mm. The theoretical maximum scan speed is not practical for ECA applications that demand high signal quality because the processing time of the eddy current signal is not long enough to reject noise that is present.

Practical sample rate (SR) for ECA applications is much lower than the theoretical maximum to allow enough processing time to produce lower noise signal. This makes high SR superfluous for ECA.

The SNR of the array probe data is an inverse function of the SR. The maximum SR will result in the worst SNR. Slowing down the SR will achieve better SNR by stretching the periods of the TS to average more samples. This will improve the detectability of small flaws. The SNR will improve by 3 dB each time that the sampling rate is cut in half. For example, a scan speed of 200 mm/sec will have an SNR that is 3 dB better than a 400 mm/sec scan speed. Slowing the scan speed down to 100 mm/sec (one-fourth) will produce an SNR that is better by 6 dB.

With higher noise levels, there is a greater chance of missing small flaws. Therefore, a high sample rate isn’t necessarily a good thing. What is more desirable is a high signal to noise ratio. Source: Zetec

SNR filtering

Software that supports single- and dual-frequency eddy current, rotating scanners, and conductivity with the viewing tools of impedance, sweep, waterfall, and C-Scans can help maximize an instrument’s ability to manage SNR and deliver an accurate, detailed inspection result.

Another software feature, SNR filtering, allows the technician to filter off low-level voltage signals and retain data above a specified range. This filter looks for and reduces the noise in the data without attenuating the real signals of interest—essentially, it lowers the “N” or noise part of the ratio without affecting the “S” or signal part. This differs from a threshold filter, which will remove everything below a certain point, including signals of interest. An SNR filter can be activated while acquiring data or, importantly, after acquisition for further analysis.

Conventional NDT methods can be time consuming, and fabricators value inspections that are quick to set up and complete while delivering a high probability of detection. For big jobs, a portable handheld ECA instrument and surface array probe can provide the right balance of inspection speed, detection capability, and cost effectiveness.

All Images Source: Zetec

Ian R. Lazarus is president and CEO of Creato Performance Solutions, providing leadership development, training, and solutions to support operational excellence.

Jesse Herrin is a mechanical design engineer and software developer who has spent 12 years working in product management and engineering roles at Zetec, a provider of NDT technology and eddy current solutions.

Jim L. Smith has more than 45 years of industry experience in operations, engineering, research & development and quality management.