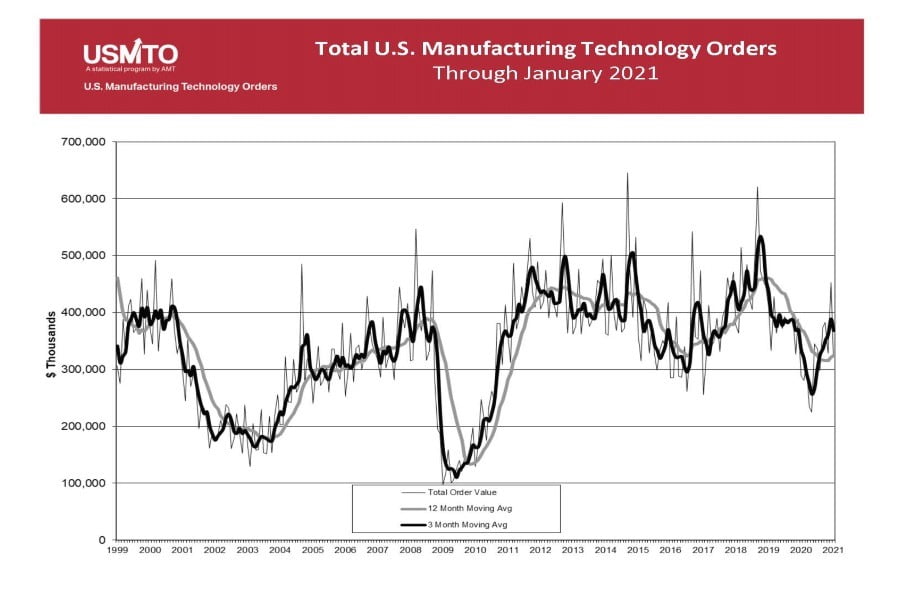

U.S. Manufacturing Technology Orders totaled $322.5 million in January 2021, a 29% decrease from December 2020, but a 12% increase over January 2020, according to the latest U.S. Manufacturing Technology Orders report published by AMT – The Association For Manufacturing Technology. This is the third straight month of year-over-year gains, a trend not seen since late 2018.

US Manufacturing Technology Orders Increase 12% Over January 2020

“It is encouraging to see that January was the third straight month of year-over-year gains in manufacturing technology orders,” said Douglas K. Woods, president of AMT. “The decline from December 2020 was expected, given the unusual strength of that month’s orders. January orders were buoyed by the largest capital equipment investments in forming technology since May 2019. The automotive sector was particularly active, as U.S. auto manufacturers are planning external body styling changes in 2021 that were postponed in 2020 due to the pandemic. The high number of January automotive orders for forming not only reflected orders planned for 2021, but also included orders planned for 2020 that were delayed until 2021.”

“Another bright spot was the mold and die sector, which after nearly a two-year decline in monthly orders, has been increasing capacity steadily since May 2020, reflecting the supply chain shifts to domestic producers. We expect that additional actions to reduce supply chain risks will maintain investment in this sector through 2021 and perhaps even be accelerated with President Biden’s executive orders to have agencies evaluate supply chains critical to manufacturing capacity”.

For more information, visit www.amtonline.org.

MxD announced that former Director of the National Institute of Standards and Technology’s (NIST) Manufacturing Extension Partnership (MEP) Carroll Thomas has joined its Board of Directors.

In her role as Director of the U.S. Department of Commerce’s NIST MEP, Thomas helped U.S. manufacturers compete globally by accessing new technology and strengthening supply chains. With more than 400 manufacturing extension offices located in all 50 states and Puerto Rico, MEP services have a measurable track record of providing manufacturers enhanced growth, improved productivity, and expanded capacity.

With more than 30 years of entrepreneurial and small business development experience, Thomas’s accomplished public and private sector career demonstrates her leadership expertise as a catalyst for creating effective partnerships and advocating economic development by supporting dynamic innovation ecosystems.

Thomas currently serves on the boards of the Information Technology Innovation Foundation and the State Department Federal Credit Union. She holds a Bachelor of Science degree from Drexel University in Design and a Master of Business Administration from Johns Hopkins University in International Business. She is now retired.

“I am thrilled to welcome Carroll Thomas to our board to bring a more intimate familiarity with the challenges and strengths of the small and mid-sized manufacturers,” said Chandra Brown, MxD CEO. “Carroll’s leadership will bolster MxD’s efforts to digitize the hundreds of thousands of smaller firms that form the backbone of the nation’s manufacturing economy.”

The addition of Thomas to MxD’s board builds upon the institute’s strong track record of working with MEP to disseminate resources to manufacturers embarking on their digital journey and seeking to improve their cyber posture.

For more information, visit www.mxdusa.org.

Former NIST MEP Director Joins MxD Board

Reshoring in the Age of COVID-19

Harry Moser, founder of the Reshoring Initiative, discusses how the pandemic has affected reshoring, the connection between reshoring and automation, and the quality improvements possible with reshoring.

Perceptron, Inc. announced that Anders Hoberg accepted the appointment for the position of Chief Executive Officer at Perceptron.

Hoberg commented, “I am honored to be appointed as Perceptron’s CEO and excited to mentor, lead, and develop the growth potential of Perceptron in the U.S. Our focus is fully integrating Perceptron into the Atlas Copco culture with a focus on market expansion for all of our machine vision solutions.”

Hoberg Appointed Perceptron CEO

Atlas Copco completed the purchase of Perceptron on December 21, 2020. Since the purchase, Atlas and Perceptron have concentrated on integrating internal systems and cultures. “Perceptron has a rich history in the metrology and machine vision industry. After forming in the early eighties, Perceptron was an independent company for many years. We want to keep their entrepreneurial spirit intact as we provide the necessary support and resources to exceed company growth goals,” said Hoberg. “To support our growth plans, Perceptron is hiring across multiple departments.”

Several job openings are available in Plymouth, including Software Development Engineers, Training Specialists, Technical Support Engineers, and Project Engineers. Visit https://perceptron.com/careers if you are interested in exploring employment opportunities with a growing company.

For more information, visit www.perceptron.com.

Faro® Technologies, Inc. announced two new strategic goals in support of its Environment, Social & Governance (ESG) efforts.

The first new goal is to reduce the company carbon emissions 25% by 2025 through aggressive activities that improve environmental performance. The second new goal is to establish middle and high school partnerships to improve curriculum in Science, Technology, Engineering & Mathematics (STEM) -- especially for minorities and females from low-income and disadvantaged areas. Year-one STEM funding will be $50,000 across the U.S, Canada, Germany, Portugal, the U.K, Singapore, and India.

“Faro is deeply committed to practicing good citizenship and global sustainability and we have a strong history of addressing ESG issues that impact the organization, our customers and the communities we serve around the globe,” said Michael Burger, president & CEO. “Whether reducing our carbon footprint, embracing ethical business practices, supporting diversity in our schools or ensuring oversight of our operations and data, corporate responsibility is a business imperative woven throughout the enterprise.”

Faro has a diverse global workforce and fosters a culture of trust that provides a safe and secure environment. Established ESG programs and policies drive operational excellence and maintain the highest standards possible for accountability, conduct and governance. The company also ensures that supply chain partners adhere to these principles and practices, including the sourcing of raw materials, as outlined in the Faro Supplier Code of Conduct policy.

Faro environmental programs include minimizing facility energy consumption, commercial travel, product transportation routes, and employee commute distance as well as recycling paper products, E-waste, and other materials (metals, plastics, rubber, and carbon fiber). Social responsibility programs include corporate giving, employee volunteerism, providing technology to advance academic research and preserve history, and offering diversity-focused internships and career opportunities to students through Faro University and the New Graduates Development Program. Governance programs include ethical and legal standards of behavior that are required of all employees and business partners and maintaining a rigorous cybersecurity infrastructure to protect sensitive employee and customer data.

For more information, visit www.Faro.com.

Faro Announces Two New Global Sustainability Goals to Advance ESG Efforts

America Makes, which represents the U.S. additive manufacturing, technology and education ecosystem released the following statement on President Biden’s supply chain executive order. John Wilczynski, executive director of America Makes, said:

“America Makes applauds President Biden's critical executive action to secure and strengthen supply chains vital to America’s continued progress. The administration's order is further validation that America's advanced manufacturing community has played a crucial role in closing supply chain gaps during the pandemic and continues to drive the U.S. innovation ecosystem by supporting U.S. technological competitiveness.

“The pandemic has revealed our untenable overdependence on imports and that the need for the capacity to respond quickly in the face of challenges is paramount for securing our supply chain and ensuring our nation’s continued security, health, and prosperity."

For more information, visit www.americamakes.us.

America Makes Applauds Supply Chain EO

Elementary Robotics recapped a successful 2020 despite the COVID-19 pandemic. The company recently moved into a larger office space in Pasadena, CA, and has significantly grown its customer base and revenues, and plans to double employee headcount in 2021 to meet strong customer demand. Elementary has also rounded out its executive team with the recent appointments of two senior executives with decades of sales, marketing, and engineering expertise who will help steer the company as it continues on its rapid growth trajectory.

Monique Apter, EVP of Sales and Marketing

Monique brings more than 30 years of sales and marketing leadership experience to Elementary. Monique served as VP of Sales and Marketing for Kindred Systems, Inc. which was acquired by Ocado. She also held executive sales positions with Rethink Robotics, and Segway.

“While manufacturers have successfully deployed robotics and other automation technologies to reduce the cost of goods to consumers and accelerate manufacturing times to meet consumer demand, the inspection process has largely remained a manual process,” said Monique Apter. “Our new AI camera system for cloud-based inspection will enable manufacturers to keep an eye on their production lines remotely and deliver top quality goods to their customers.”

Milind Karnik, EVP of Engineering

Prior to joining Elementary, Milind was Senior Vice President of Engineering at Cylance which was acquired by Blackberry at the end of 2018 for $1.4 billion. He has also held senior engineering positions at QLogic, LSI Corporation, Dell and Intel.

“I am thrilled to welcome two new leaders to our executive team,” said Arye Barnehama, founder and CEO of Elementary Robotics. Both Milind and Monique have proven track records and bring the leadership philosophy that will be invaluable as we continue to grow the organization and provide our customers with the advanced level of automation and precision to manufacturing inspection they deserve.”

For more information, visit https://www.elementaryrobotics.com.

Elementary Robotics Appoints New EVP of Sales and Marketing, EVP of Engineering

Korea also leading the pack, but Germany falters

Rubber and plastics machinery sector gains new significance in the light of the pandemic

Semiconductors and electronics machinery sector emerges virtually unscathed

Manufacturing Industry Output (MIO) 2020 Contraction Lower Than Expected; Driven by Growth in China

The latest quarterly update to the Manufacturing Industry Output (MIO) Tracker from Interact Analysis reveals unexpectedly strong overall global manufacturing performance. This is an upward revision on the previous MIO updates. At our most pessimistic point, we forecast a -4% contraction in industrial output for China. But the country’s rigorous suppression of the virus meant that production was back on track by May 2020, and the region is now posting 1.9% growth.

The Chinese recovery has had a significant impact on global growth, but it still represents considerable overall lost growth, putting China among the four global loss-leaders, along with India, Japan, and the USA, who have together racked up in excess of $200bn in lost MIO potential. Korea’s track-and-trace strategy has been hugely effective, and the country has seen strong growth in the electronics and components sectors resulting in overall negative growth of only -2.4% for 2020.

In Europe, Germany’s economy in particular has suffered, and recovery will be sluggish. Key factors here are the country’s huge reliance on export markets in Eastern Europe and globally, notably in the automotive and metals sectors which have both fared badly in the pandemic.

Where industrial machinery is concerned, one of the biggest casualties globally has been the machine tools sector, which has been hit hard by the major slow-down in the transportation industries. In Germany, machine tools is down 30% and this is reflected in weak performance in other European countries too, such as the UK where we also predict the machine tools market to be down over 30%. And Europe is not alone: few of the major regions are likely to return to 2019 levels in the next 6 years.

COVID-19 has driven, and will continue to drive, the demand for plastic and rubber medical supplies and personal protective equipment. However, the rubber and plastics machinery sector did experience a decline in demand in 2020 with Korea, India and the UK seeing contractions of the order of -15.8%, -13.9% and -13.4% respectively. However, all the top 10 regions are expected to recover to 2019 levels by 2023 at the latest. Strong APAC performance will bolster a growth that will see production values rise from $49.6bn in 2020 to $53.4bn in 2021.

Adrian Lloyd, CEO at Interact Analysis, says: “The Semiconductor and electronics machinery sector is one of the few sectors to have come through the pandemic untouched. Most major regions are forecast to grow past 2019 levels in 2020, with global growth forecast at 9.9%. The few who don’t will be back up and running at a stronger level than 2019 by 2021. Growth will likely be slightly slower in 2022 and 2023 but will remain positive. APAC is the leading producer of semiconductor and electronics machinery. We forecast a 5-year CAGR for Korea of 9.1%. It’s a good sector to be in. But some regions really need to play catch-up.”

For more information, visit www.InteractAnalysis.com.

Applied Automation Technologies Joins Andretti Autosport as Official Metrology Solution

Andretti Autosport announced that Applied Automation Technologies (AAT3D) will serve as the team’s official metrology solution. AAT3D began in 1987 as a CAD-based dimensional measurement software and developed into a global leader of software solutions for metrology, quality control and manufacturing systems.

"For over 30 years, Applied Automation Technologies (AAT3D) has been an industry leader in on-machine metrology to improve precision manufacturing processes and quality standards," said Ray Karadayi, CEO, Applied Automation Technologies. "We are excited to partner with Andretti Autosport as a technical sponsor and provide our expertise. The Andretti name is legendary in autosport and we look forward to being a part of the team."

Over the years, AAT3D has been able to create on and offline programs for their software including the CAPPSNC software. AAT3D’s CAPPSNC software allows measurement programs the ability to develop offline while directly running the program software on CNC machine tools. The AAT3D measurement software works with Andretti Autosport’s Siemens NX CAD software and DMG MORI machine tools, improving quality and efficiency in the manufacturing process. With the transition of dimensional inspection process to the CNC machine, a closed-loop feedback system is created allowing to yield higher accuracy, fewer defects and reduced post inspection time.

"We’re very excited to establish a relationship with Applied Automation Technologies," said Scott Graves, engineering manager at Andretti Autosport. "Their innovative metrology automation software will help us achieve a new level with our manufacturing processes and bring better parts to the racetrack. AAT3D will be a valuable addition to our family of technical partners."

Using AAT3D’s software amongst Andretti Autosport’s machinery will allow the team to focus on quality control in dimensional measurements and the overall machining process.

For more information, visit www.AAT3D.com.

America Makes announced a new Rapid Innovation Call (RIC) worth $185K in total funding from the Air Force Research Laboratory (AFRL), Materials and Manufacturing Directorate, Manufacturing and Industrial Base Technology Division, to advance qualification and certification (Q&C) of additive manufacturing (AM) materials, processes, and products throughout the supply chain.

“We have been encouraging our membership community to submit topic ideas for subsequent RICs,” said Brandon D. Ribic, Ph.D., America Makes technology director. “We received tremendous support evidence by the high number of quality suggestions. While today’s RIC announcement encompasses three topics with unique technical focuses, they share a unified goal of advancing qualification and certification as a means to removing a recognized industry barrier to the broader adoption of additive manufacturing technologies.”

This RIC will address the needs of the membership in three topic domains:

Topic 1: Characterization of Metal AM Process Surface Features

The technical focus of this project is the development and demonstration of in-situ process monitoring for metal AM surface features. The goal is to expand the industry understanding of metal AM and establish a quantitative data set to refine best practices, which will subsequently contribute to Q&C standards. As this is a Member Driven RIC, there is no cost share requirement for this project call.

Topic 2: AM Part Families for Product Qualification & Certification (Q&C)

The technical focus is to leverage existing AM data to create AM part families to increase the amount validated AM data within the public domain and develop Q&C standards. The goal is to drive broader adoption of AM in such specific industries as aerospace, medical, and aviation where Q&C of AM parts is critically needed. As this is a Government Driven RIC, this call has a cost share requirement of 25 percent.

Topic 3: Development of Test Artifacts for the Characterization of AM In-situ Process Monitoring Systems

The technical focus of this project is to use test artifacts or geometric feature sets to evaluate the performance of in-situ process monitoring in metals-based AM commercial systems. The goal is to increase AM fabrication and AM parts quality in real-time instead of quality analysis after fabrication. As this is a Government Driven RIC, this call has a cost share requirement of 25 percent.

For more information, visit www.americamakes.us/project-calls.

America Makes Announces New Rapid Innovation Call Totaling $185K in Funding

The Manufacturing Leadership Council, a division of the National Association of Manufacturers, has announced the election of Mary Beth Heydrick, vice president of operations for Dow’s performance materials and coatings business segment and operations in North America and a member of Dow’s operations leadership team, to the MLC’s Board of Governors. The MLC is the nation’s foremost executive leadership organization dedicated to driving transformational growth for manufacturing companies along their digital journey to Manufacturing 4.0.

In addition to Heydrick’s appointment, MLC Co-Founder, Vice President and Executive Director David R. Brousell was officially appointed to the MLC Board of Governors as the MLC’s direct representative. The Board of Governors also reelected John Fleming, former executive vice president of global manufacturing and labor affairs at Ford, and Mike Packer, director of production strategy at Lockheed Martin Aeronautics, as MLC Board chair and vice chair, respectively, for another year.

The MLC Board of Governors approved Heydrick’s nomination in a unanimous vote. With this appointment, the MLC Board consists of 19 industry thought leaders who represent the full ecosystem of the manufacturing industry, which includes large global enterprises, small and medium-sized manufacturers, leading academic institutions and influential industry analysts.

As an advisory body, the MLC Board of Governors provides guidance to the MLC on its “critical issues” agenda, research studies and programs and services for the MLC membership. Dow has been a committed and highly engaged MLC member for many years.

“I am delighted to welcome Mary Beth to the Board,” said Fleming. “We look forward to working with her and benefiting from her extensive manufacturing industry experience and insights.”

“The role manufacturing plays in driving both economic and social prosperity is a true passion of mine,” stated Heydrick. “The MLC provides a critical voice as companies navigate the ever-changing landscape facing all manufacturers. I look forward to being part of the MLC Board of Governors and providing my insight and expertise now and in the future.”

Heydrick first joined Dow in 1989 and has held a variety of roles of increasing responsibility in both the U.S. and Europe. As vice president of operations for one of Dow’s business segments and geographic regional areas, she is accountable for operations at many of Dow’s locations across the globe. In addition to her day-to-day responsibilities, Heydrick serves as the Asian Diversity Network North America sponsor, is a strong supporter of Dow’s Women’s Innovation Network, is a council member for Dow’s Global African American Network and is a member of the Society of Women Engineers. She holds a degree in chemical engineering from Michigan State University, is a certified Six Sigma Black Belt and is a recipient of The Manufacturing Institute’s STEP Ahead Award, which recognizes women in science, technology, engineering and production careers who exemplify leadership within their companies.

Heydrick replaces former Dow MLC board member David Mongrue, who served on the MLC Board since 2017 and is now retired.

For more information, visit www.manufacturingleadershipcouncil.com.

Dow VP Mary Beth Heydrick Joins the Manufacturing Leadership Council’s Board of Governors

The Manufacturing Institute’s Center for Manufacturing Research and national CPA and advisory firm BKD released results from their first survey of small and medium-sized manufacturers. Manufacturing leaders were asked to describe the “new normal” for operations in the wake of the COVID-19 pandemic.

Key survey findings include the following:

More than 77% expect to continue struggling to identify talent in 2021 and beyond.

Nearly 64% had reevaluated what work could be done remotely where possible.

More than 83% had enhanced workplace safety measures and requirements.

“It may seem like a paradox, but even with pandemic-induced unemployment, manufacturers are still facing challenges finding the workers they need. With about half a million jobs open in manufacturing, that need is great—perhaps even greater than before the pandemic,” said Center for Manufacturing Research Director and National Association of Manufacturers Chief Economist Chad Moutray. “These findings continue to demonstrate the importance of The Manufacturing Institute’s efforts to reduce the skills gap and get more people onto modern manufacturing career paths—including through its Creators Wanted campaign with the National Association of Manufacturers.

“The survey also reveals the diverse ways that small and medium-sized manufacturers have adapted to the pandemic—and what they expect in the coming months. It captures manufacturers, in their own words, describing the future of everything from virtual work and flexible schedules to new product lines and price pressures.”

“BKD is proud to partner with The Manufacturing Institute on this survey. It is clear the pandemic has had a significant impact on small and medium-sized manufacturers,” said BKD CPAs & Advisors National Industry Partner John Mather. “Not all the impacts are the same, and the results show a variety of concerns. With that in mind, The Manufacturing Institute continues to play an important role is assisting these businesses with their challenges. Creators Wanted is a great example of how The Manufacturing Institute is making an impact.”

View the full survey at https://www.themanufacturinginstitute.org/research/the-manufacturing-institute-bkd-small-and-medium-sized-manufacturers-survey/.

New Survey Details “New Normal” for Small and Medium-Sized Manufacturers Amid Pandemic

Completing a 21-year career at Brunson Instrument Company, General Manager Richard Powell will retire later this year. The company has initiated a vigorous search for Powell’s replacement, and he will continue in his current capacity until the position is filled.

Powell to Retire from Brunson Instrument in 2021

“Many of our manufacturing and operational innovations are a result of Richard’s vision and perseverance—providing us the ability to best serve our growing customer base,” said Deighton Brunson, the company’s CEO. “Richard’s accomplishments at Brunson have transformed us into a modern company.”

Powell began working with Brunson in 1998 as a management consultant, and, soon after joining the company full-time in January of 2000, accepted the challenge of re-organizing the manufacturer’s multiple-line production processes. Under his guidance Brunson became ISO-compliant in 2008 and has successfully applied Lean production management processes and the Theory of Constraints.

“The Brunson brand is recognized by metrology professionals around the world, and Richard has worked hard to help guide the company to this position,” said Brunson Board Member David J. Morse, former SVP, managing director—Americas at FARO Technologies, Inc. “Richard’s retirement will be well-earned, and the board will be diligently seeking a company president to fill his shoes,” he added.

“Attracting a ‘President’-level leader makes sense for Brunson,” said Mike Tracy, HR consultant and Brunson Board Member. “And our search will focus on candidates with a strong background in business development and market expansion,” he added. Powell will continue on the company’s Board of Directors after the transition.

“I have always said that I want to leave the company better off and ensure that it is positioned to grow to the next level,” said Powell in an announcement to Brunson’s employees. “Brunson has given me fantastic opportunities and experiences over the last twenty years,” he added, “I am very grateful and appreciative.”

For more information, visit http://www.brunson.us.