Quality-related inspection is an essential part of manufacturing. Time and time again, those manufacturers and companies that ignore, or even skirt, the inspection process find themselves at risk of product failure or non-compliance with manufacturing standards, leading to product recalls and irreparable damage to their company’s brand and ability to be competitive—or worse.

Inspection Equipment

To View all Suppliers of Inspection Equipment Click Here

2024 BUYERS GUIDE eBOOK

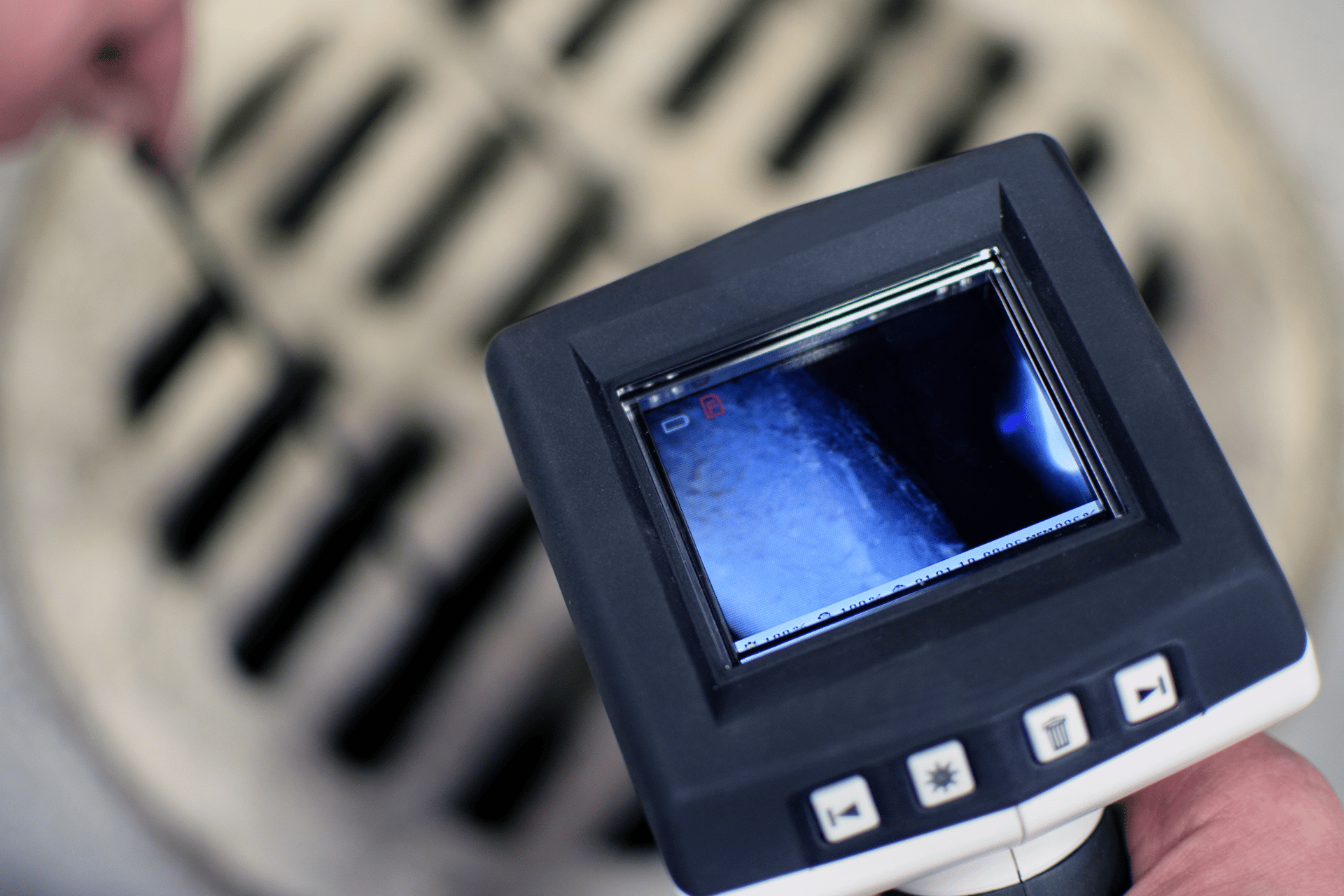

As the manufacturing process has become increasingly faster and more complex, it has become impossible to rely solely on humans to ensure this essential part of manufacturing. Enter inspection equipment. At its heart, the characteristics of what is produced during the manufacturing process is compared with its original design specifications—or against manufacturing standards—to determine whether the requirements have been met, and today’s inspection equipment can do so in astonishingly little time, at incredibly more finite tolerances, and with seemingly little human interaction. Examples of inspection equipment range from common gages, calipers, and micrometers to complex visual inspection systems that can include digital microscopes and laser trackers, just to name a few.